Full-automatic electric rice cooker

An electric rice machine, fully automatic technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of rice flour residue, difficult to disassemble and scrub the rice washing device, rice flour odor, etc., to reduce space, reduce disinfection and spray washing The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

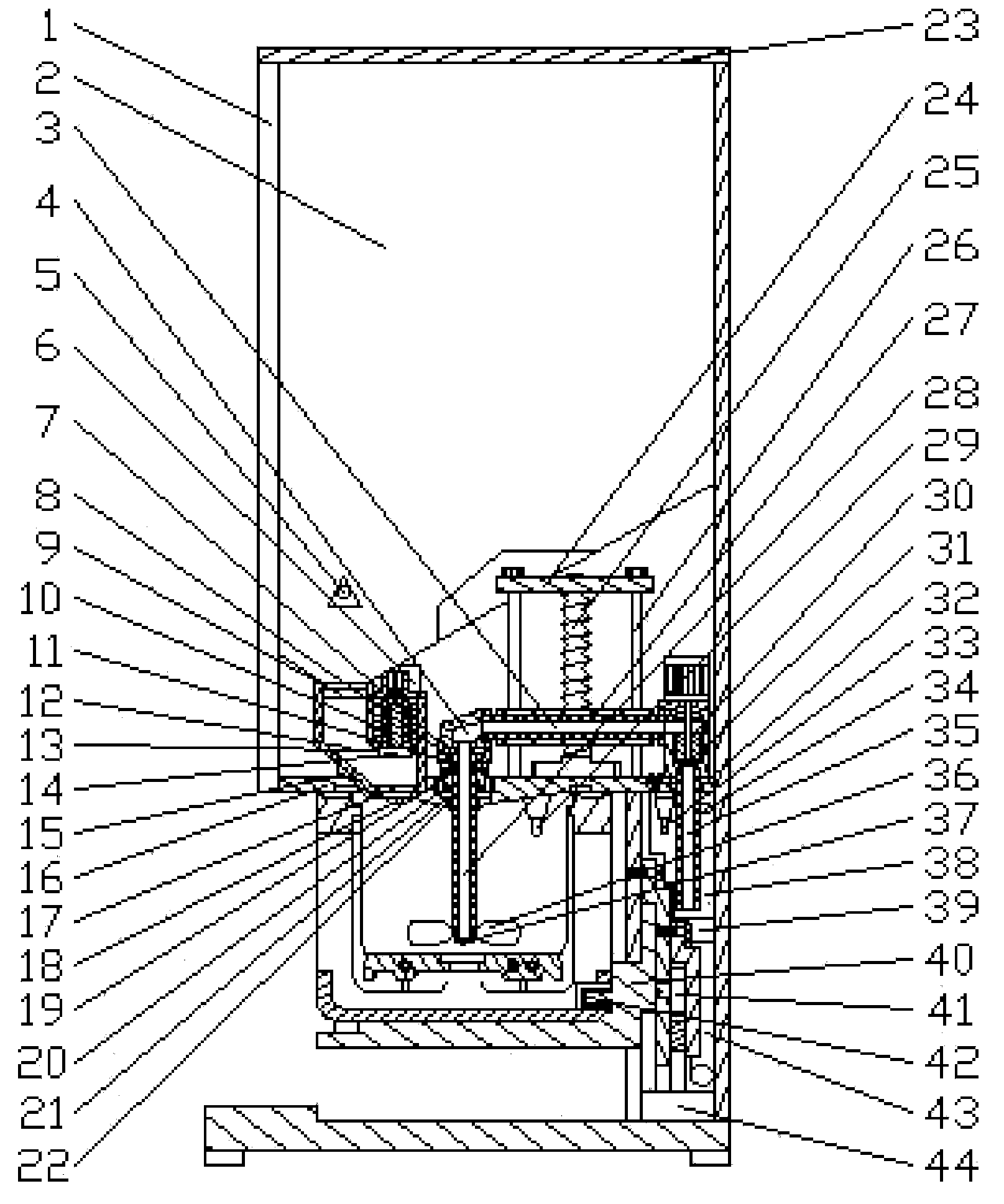

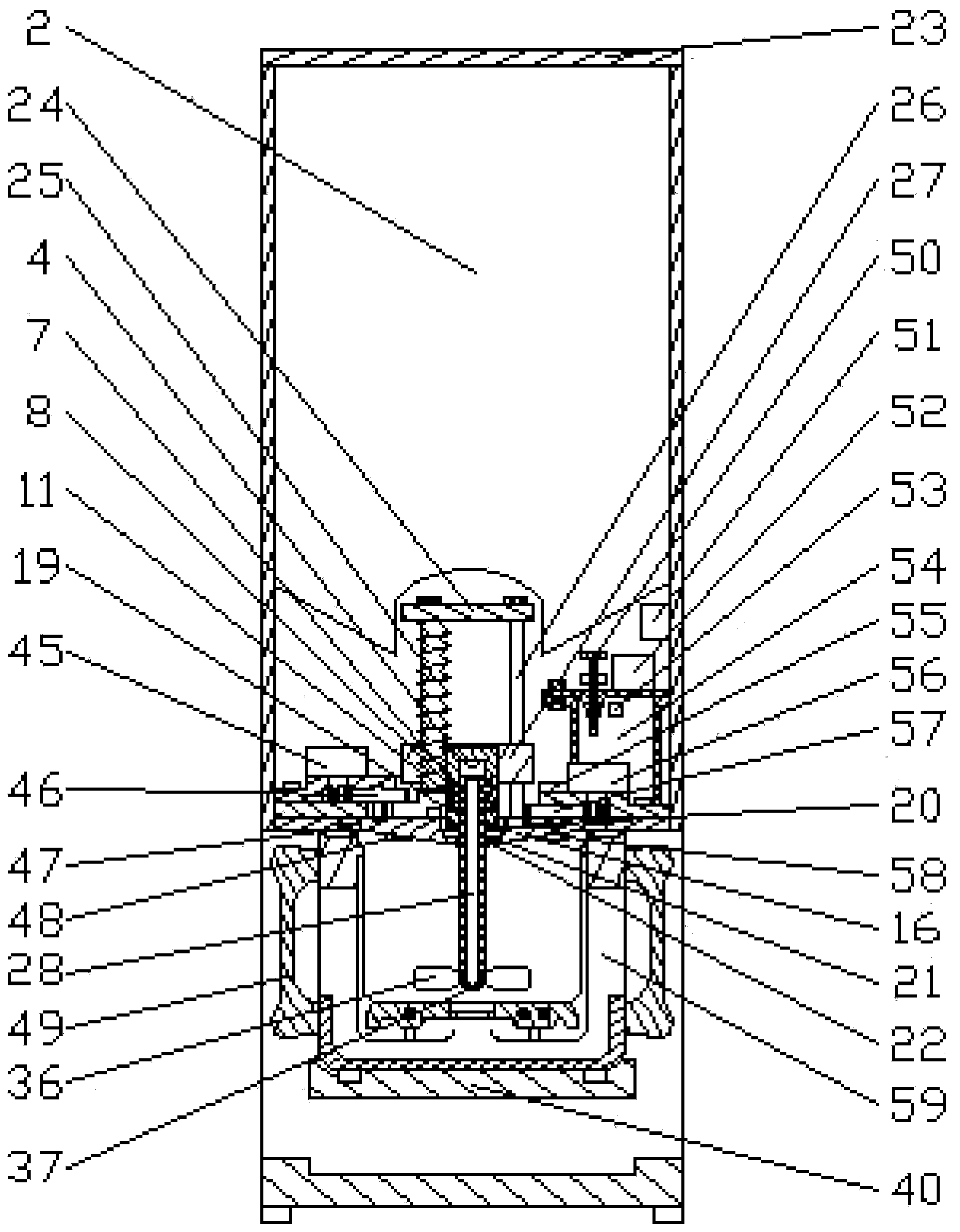

[0018] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0019] control figure 1 with figure 2 , the fully automatic electric rice machine of the present invention is formed by sequentially connecting the rice storage bin 2, the rice measuring cylinder 12, the steam plate 16, and the electric rice cooker 59 from top to bottom.

[0020] The specific parts and components of the fully automatic electric rice machine body 1, rice storage bin 2, drainage connecting pipe 3, drainage connector 4, rice shortage detector 5, rice gate tractor 6, metal ring sheet 7, connecting sealing ring 8. Rice inlet gate 9, brake core spring 10, nut cover 11, rice measuring cylinder 12, sealant rubber sleeve 13, rice release gate core 14, water spray valve 15, steam plate 16, rice release gate 17, water spray hole cover 18. Clutch gear 19, rice washing gear sleeve 20, metal shaft plate 21, rice washing sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com