Method and apparatus for the plasma processing of filter material

一种等离子、滤嘴的技术,应用在吸烟制品例如香烟的滤嘴领域,能够解决残留、污染等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

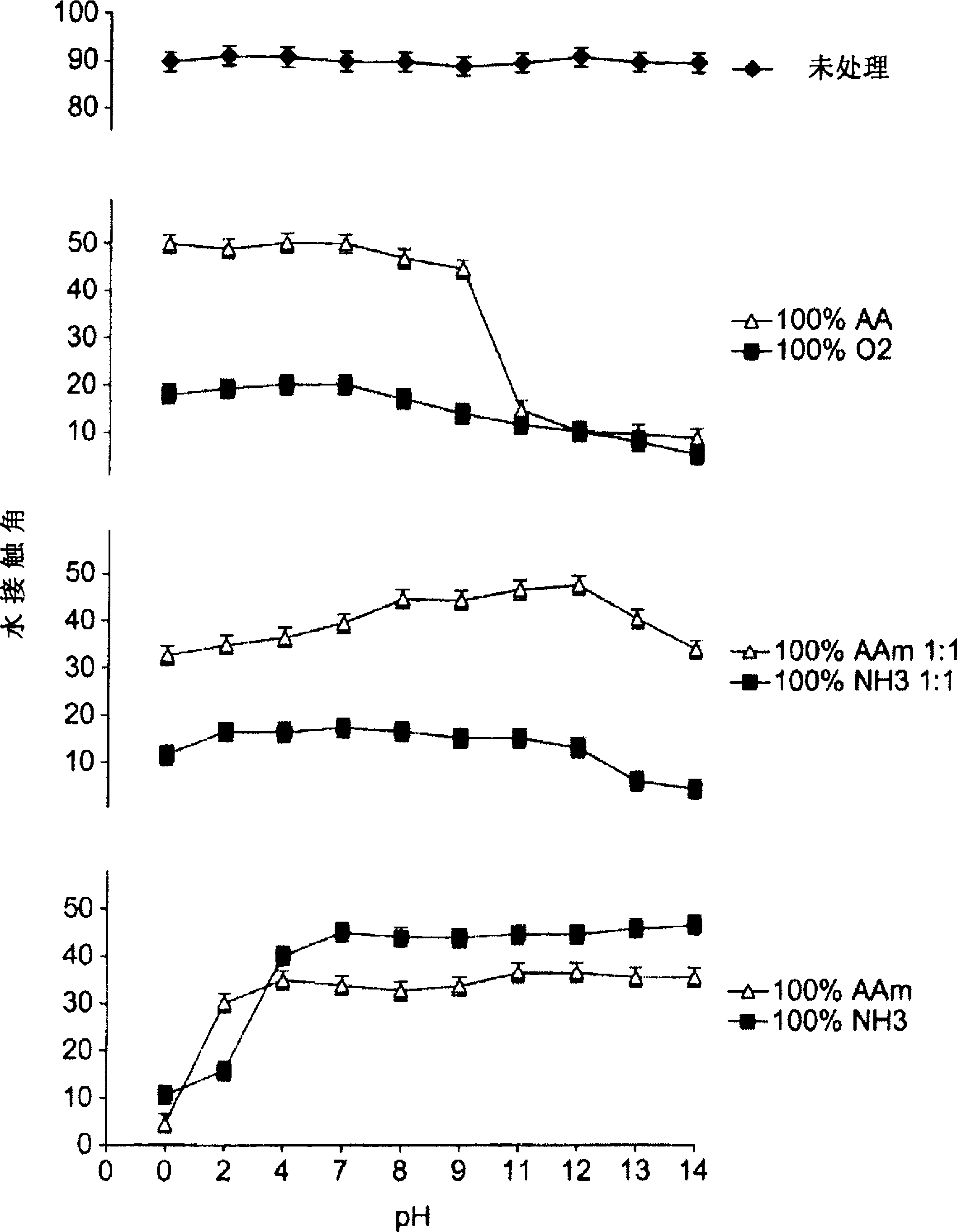

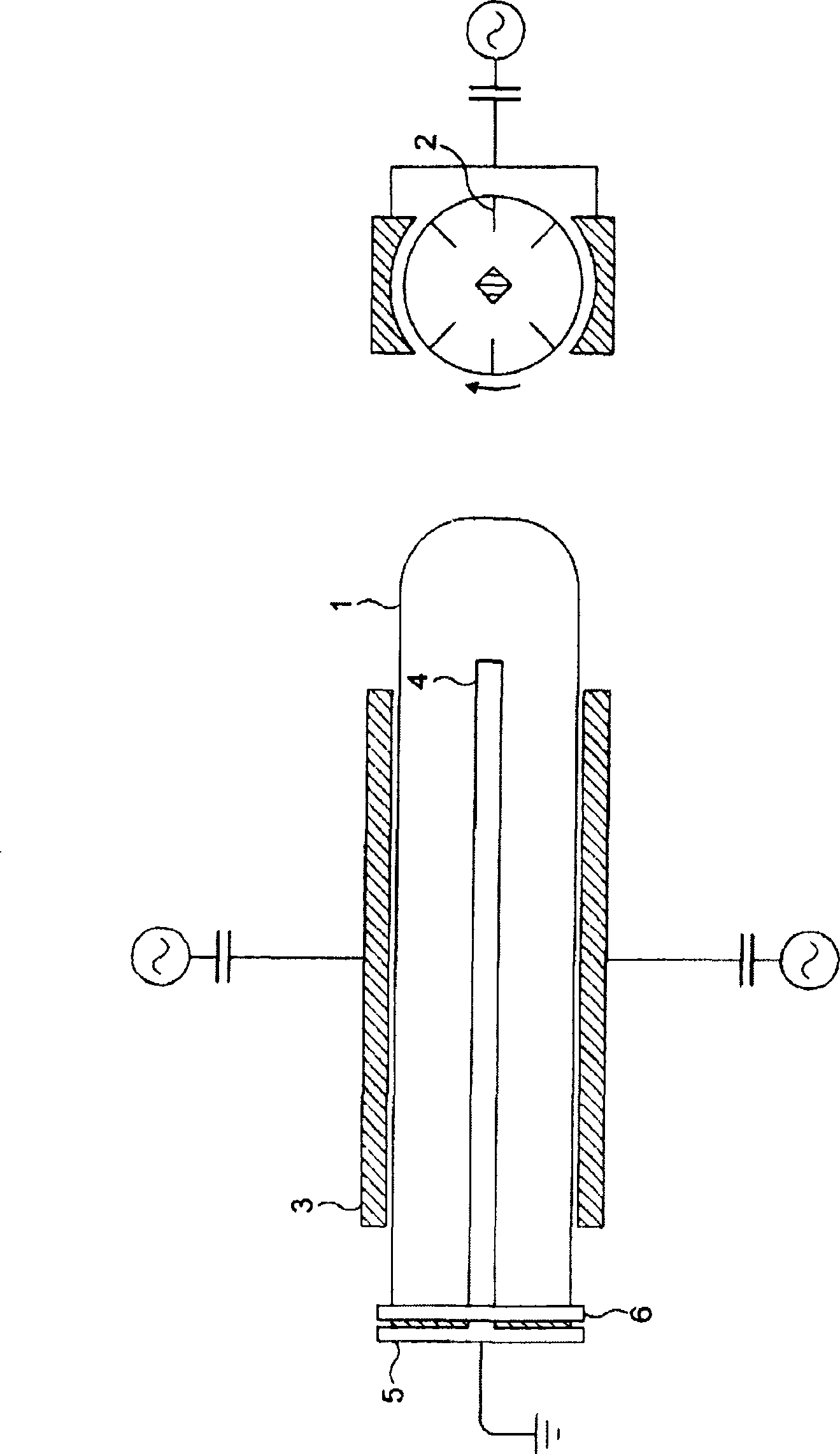

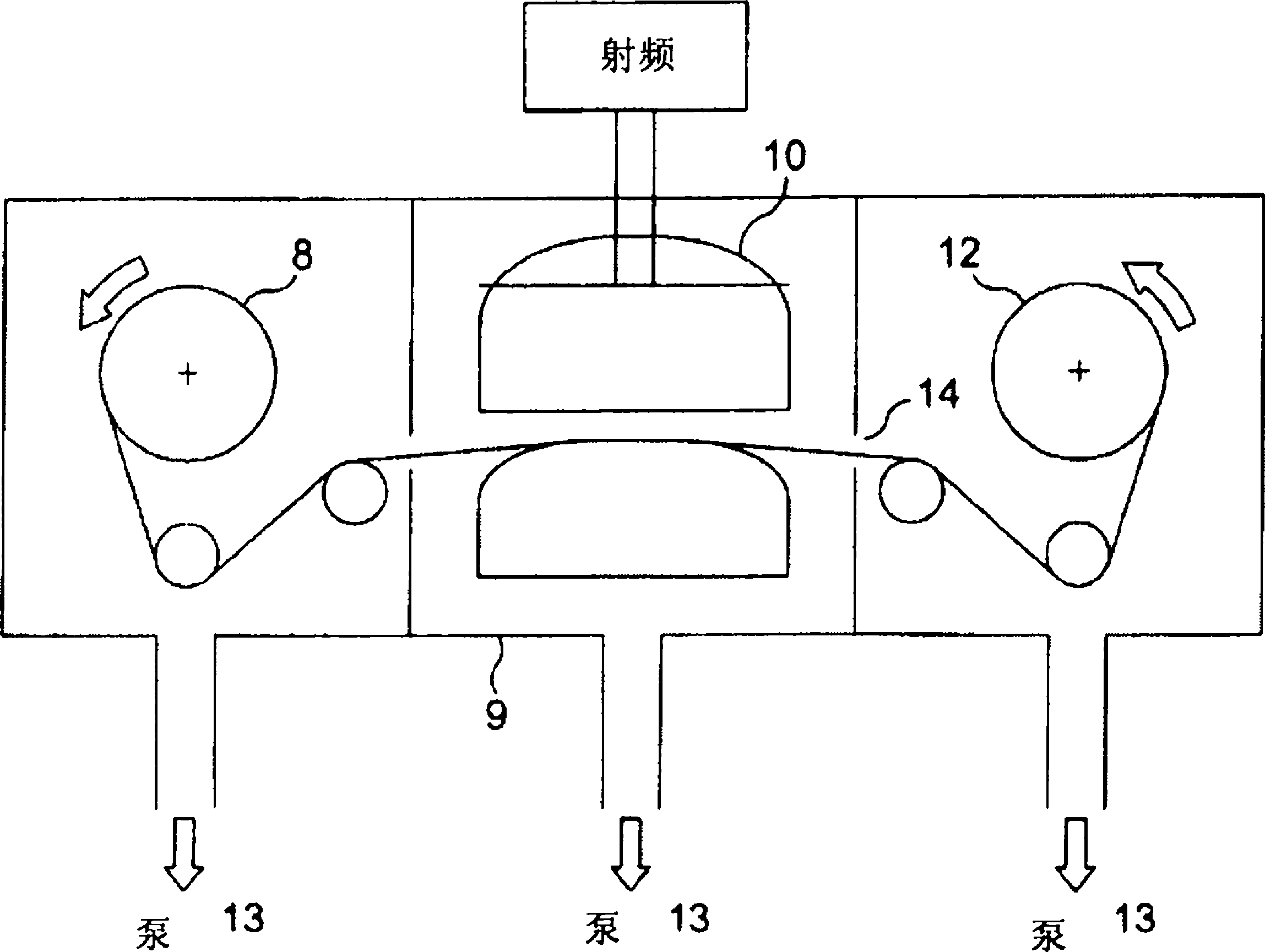

[0025] plasma treatment process

[0026] Low-pressure non-equilibrium cold plasmas (eg, room-temperature plasmas rather than hot plasmas at thousands of degrees) provide an effective tool for modifying the surface composition and topography of materials without altering their bulk properties. Plasma treatment processes are well known in a variety of different industries, including microelectronics, semiconductors, food and medical packaging, automotive, corrosion protection and biomaterials. The three main classifications of plasma processing processes that can be defined are: plasma etching, the ablation of materials by generating volatile products after the interaction of materials with active species generated in the plasma; plasma enhanced chemical vapor deposition (PE-DVD), the deposition of thin (5-1000nm) organic or inorganic coatings; and plasma treatment, which uses glow discharge to graft functional groups on the material. The grafted functional groups may be partly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com