Method for preparing titanium dioxide film with bulges on surface

A titanium dioxide and thin film technology is applied in the field of preparation of titanium dioxide thin films to achieve the effects of simple preparation method, broad research value and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

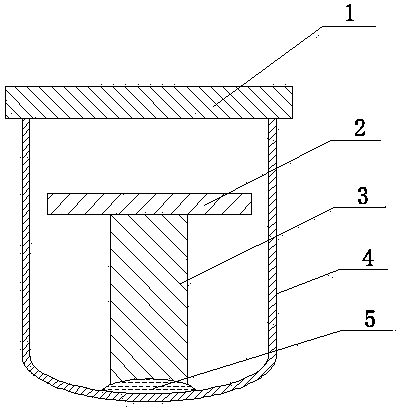

[0032] Step 1. Using liquid butyl titanate as the titanium source 5, take 1ml of butyl titanate and drop it into the crucible during the experiment, and set up a cleaned and dried quartz glass support 3 with a height of 3 cm in the middle of the inner bottom wall of the crucible 4 , and take a washed and dried square conductive glass substrate 2 with a size of 1.5cm×2cm and put it on the top of the support 3, and then cover the crucible cover 1;

[0033] Step 2. Place the crucible 4 in step 1 in a box-type heating furnace, adjust the temperature in the box-type heating furnace to 200°C and keep it warm for 30 minutes, and then a titanium-containing film can be obtained on the conductive glass substrate 2;

[0034] Step 3: Adjust the temperature in the box-type heating furnace to 450°C and keep it warm for 2 hours, then stop heating and cool to room temperature at a rate of 300°C / min to obtain the product.

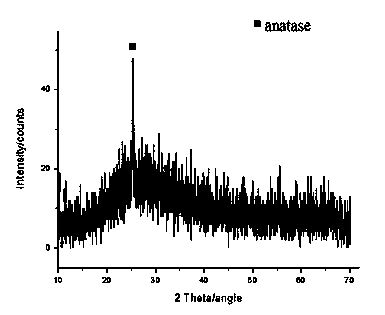

[0035] Observing the prepared titanium dioxide thin film of above-ment...

Embodiment 2

[0040]Step 1. Use liquid butyl titanate as the titanium source 5. During the experiment, take 1ml of butyl titanate and drop it into the crucible 4, and set up a cleaned and dried quartz glass support with a height of 3 cm in the middle of the inner bottom wall of the crucible 4. 3. Take a washed and dried square glass substrate 2 with a size of 1.5cm×2cm and put it on the support 3, and then cover the crucible cover 1;

[0041] Step 2. Place the crucible 4 in step 1 in a heating furnace, adjust the temperature in the heating furnace to 100° C. and keep it warm for 30 minutes to obtain a titanium-containing film on the glass substrate 2;

[0042] Step 3: Adjust the temperature in the heating furnace to 450°C and keep it warm for 2 hours, then stop heating and cool down to room temperature at a rate of 300°C / min to obtain the product.

[0043] Take the surface film of the film prepared in the above step 3 as a sample, put the sample into a test tube filled with absolute ethanol...

Embodiment 3

[0046] Step 1. Use liquid butyl titanate as the titanium source 5. During the experiment, take 1ml of butyl titanate and drop it into the crucible 4, and set up a cleaned and dried quartz glass support with a height of 3 cm in the middle of the inner bottom wall of the crucible 4. 3. Take a washed and dried square glass substrate 2 with a size of 1.5cm×2cm and put it on the support 3, and then cover the crucible cover 1;

[0047] Step 2. Place the crucible 4 in step 1 in a heating furnace, adjust the temperature in the heating furnace to 250° C. and keep it warm for 30 minutes to obtain a titanium-containing film on the glass substrate 2;

[0048] Step 3: Adjust the temperature in the heating furnace to 500°C and keep it warm for 2 hours, then stop heating and cool to room temperature at a rate of 300°C / min to obtain the product.

[0049] Take the surface film of the film prepared in the above step 3 as a sample, put the sample into a test tube filled with absolute ethanol and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com