A self-starting permanent magnet synchronous motor with magnetic and conductive composite tooth structure

A technology of permanent magnet synchronous motor and compound teeth, which is applied in the direction of synchronous motor with stationary armature and rotating magnet, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., which can solve the problem of long starting time and large current , waste of electric energy and other issues, to achieve the effect of small speed fluctuation, large torque and strong eddy current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0022] Embodiment example of the present invention is described in detail below in conjunction with accompanying drawing and basic principle:

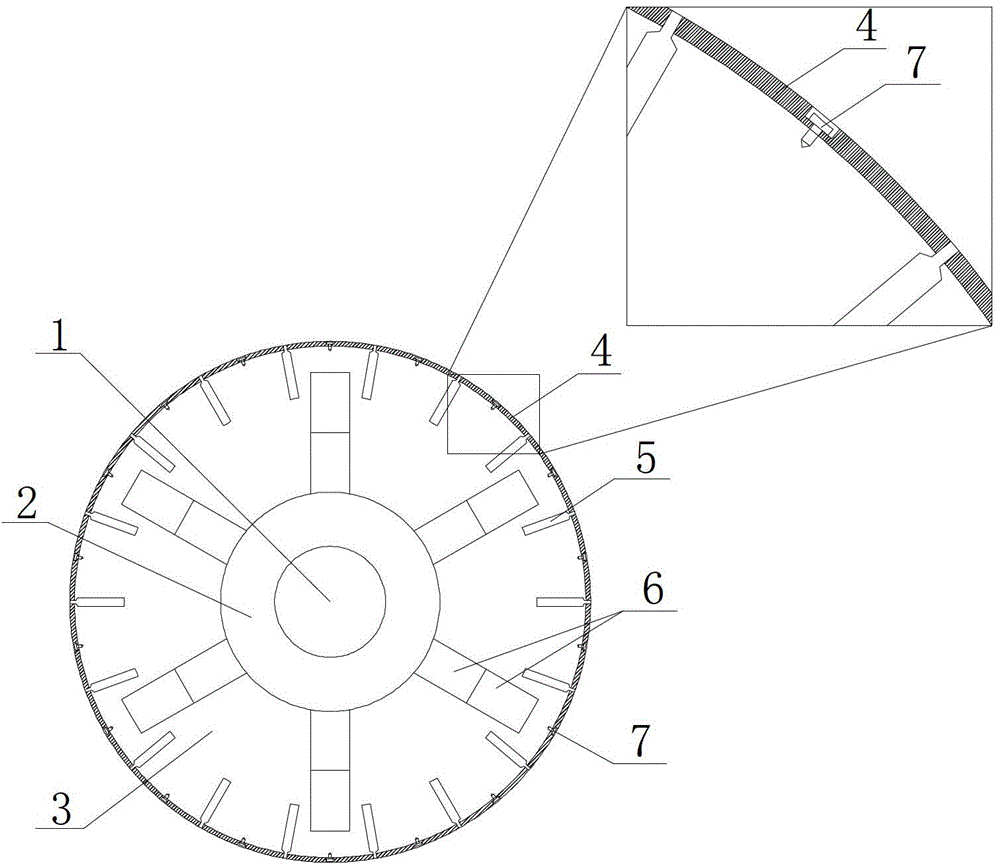

[0023] Such as figure 1 As shown, a self-starting permanent magnet synchronous motor with a new magnetic and conductive composite tooth structure is mainly in that the rotor core 3 is pressed from silicon steel sheets, the top of the motor rotor is made of magnetic and conductive solid composite material 4, and the rotor is made of yellow The cage bar made of copper or the cast aluminum cage bar 5 is close to the surface of the rotor, the permanent magnet 6 can adopt a built-in tangential magnetic circuit structure, and the magnetic isolation ring 2 is used between the permanent magnet 6 and the rotating shaft 1; The thickness of the solid composite material 4 is determined by the magnetic and conductive properties of the composite material. By adjusting the size of the composite material 4, a small starting current and a large startin...

Embodiment approach 2

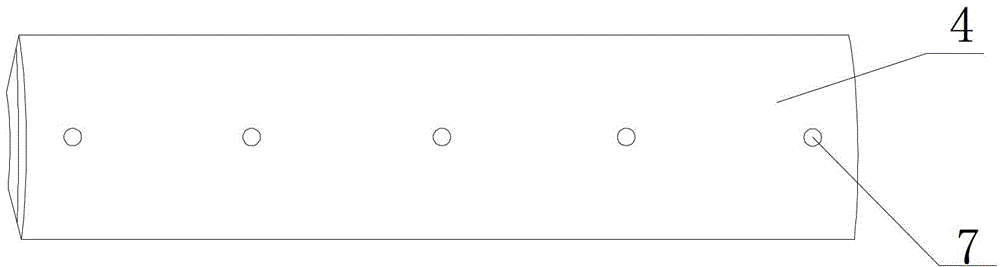

[0031] There is a dovetail groove 7 on the teeth of the laminated iron core in contact with the composite tooth material. The composite material used in the dovetail groove 7 is connected with the tile-type composite material. When installing, the composite material in the shape of the dovetail groove 7 flows from the The end is passed into the dovetail groove 7, and the effect of centrifugal force can be overcome by the structure of the dovetail groove 7, such as image 3 . The basic principle of operation is the same as that of Embodiment 1, and it is also applicable to occasions of frequent starting and heavy-load starting.

Embodiment approach 3

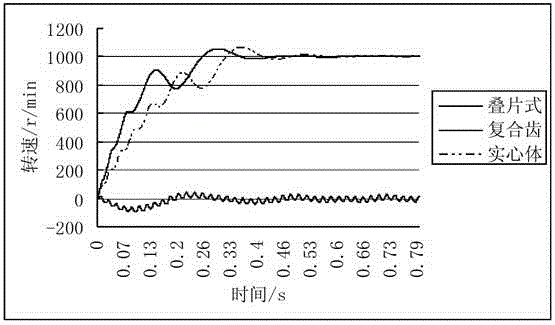

[0033] By optimizing the structure of the compound tooth part, adjusting its width and thickness to reduce the eddy current loss when the motor runs stably. Figure 4 A schematic diagram of the adjusted structure is given. The composite material is placed in the dovetail groove 7 to overcome the centrifugal force during operation. The starting principle is the same as that of Scheme 1. After the solid body stabilizes, the eddy current loss is 2.59kW, and the eddy current loss of the compound tooth is only 2.14kW, but the starting time is about 0.4s longer than that of the solid rotor. Therefore, it can be seen that the starting performance of this scheme is better than that of the laminated rotor, and at the same time, the eddy current loss generated in the stabilized solid composite material is smaller than the eddy current loss generated by the ordinary solid iron core rotor, which effectively improves the efficiency. Therefore, this solution is suitable for the long-term ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com