Combined printing circuit board electric capacitance tomography sensor

A technology of capacitance tomography and printed circuit board, which is applied in the direction of material capacitance, etc., to achieve the effects of reducing error, reducing the influence of dielectric coefficient, and flexible adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

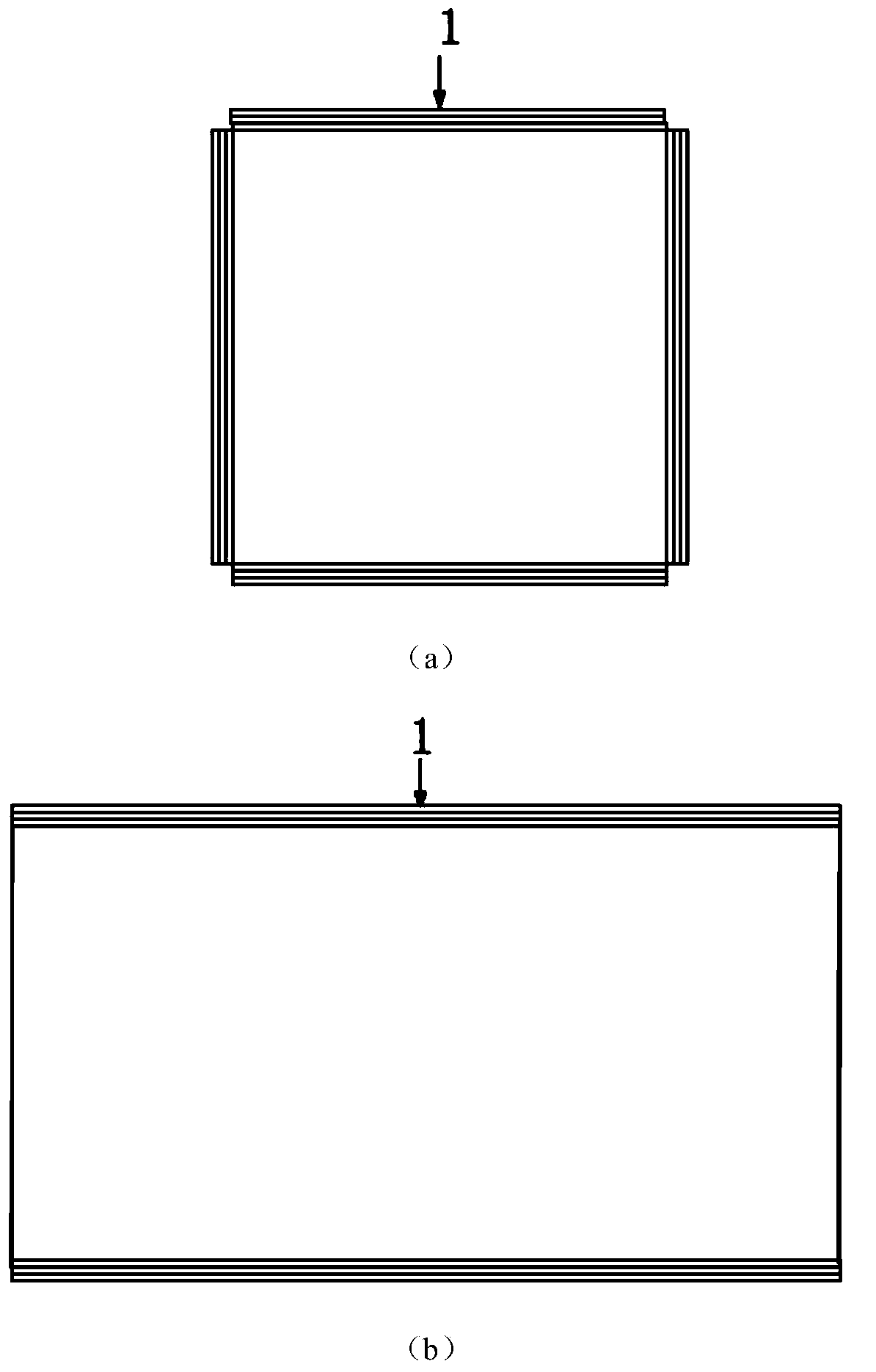

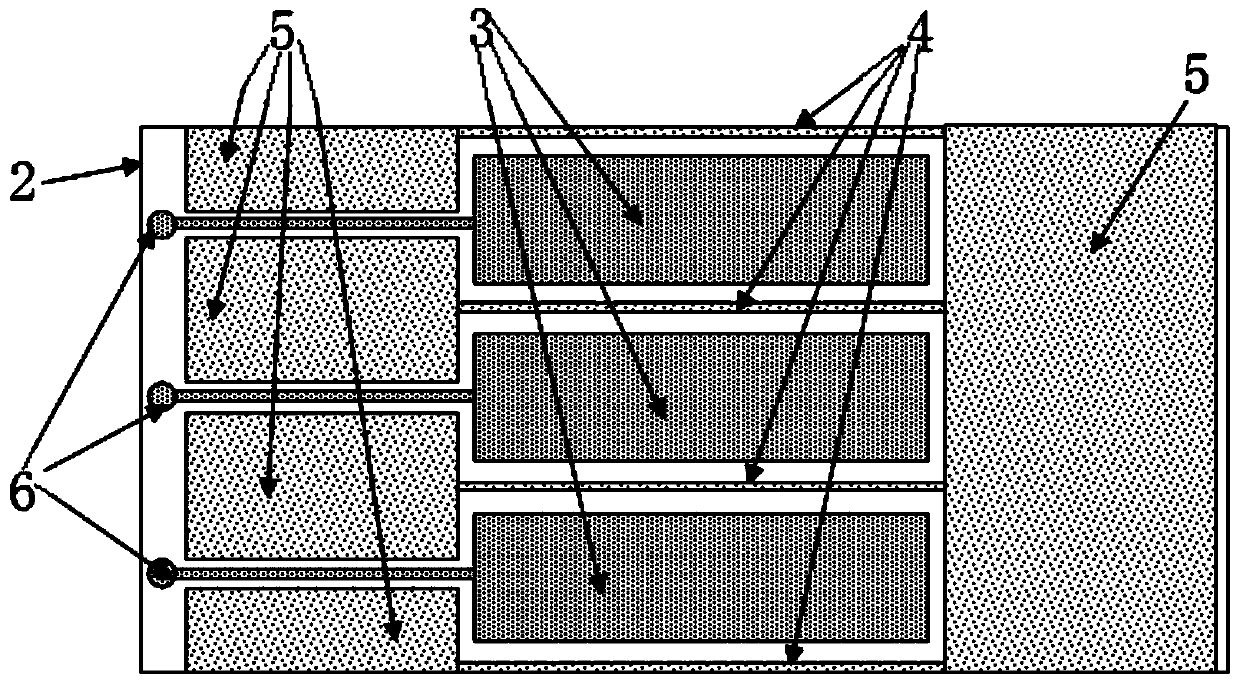

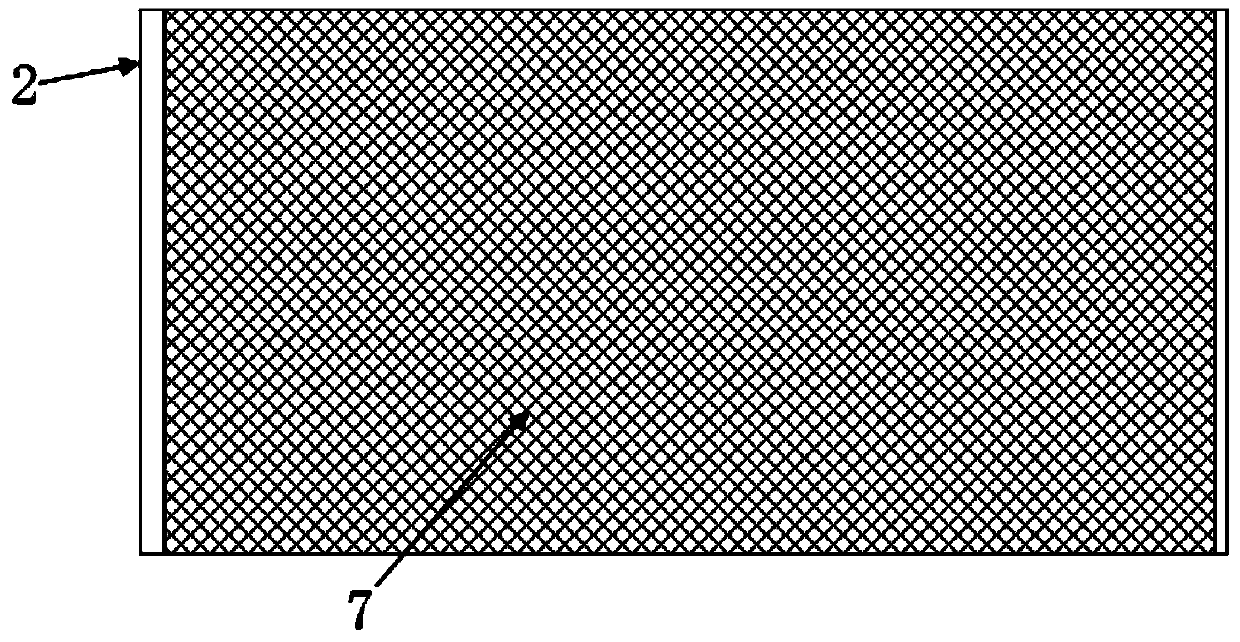

[0025] figure 1 It is a schematic diagram of a sensor composed of four measuring electrode modules provided by the present invention; among them, (a) is the front view of the sensor; (b) is the left side view of the sensor; the front view shows four blocks of upper, right, lower and left Measuring electrode module 1, four measuring electrode modules 1 are combined into a frame structure, the left side view shows the left module of the sensor, and the upper and lower modules. The measuring electrode module 1 adopts the structure of a three-layer printed circuit board, including an inner board, an electrode array board and an outer board; the inner board forms the inner wall of the measurement channel; the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com