High-speed precision rotating shaft being sealed by high-pressure gas

A rotating shaft and high air pressure technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve problems such as damage, easy wear of oil seals and sealing rings, and affecting the sealing performance of the rotating shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiment given below intends to further illustrate the present invention, but can not be interpreted as the restriction to protection scope of the present invention, those skilled in the art still belongs to the protection of the present invention to some non-essential improvements and adjustments of the present invention according to the content of the present invention scope.

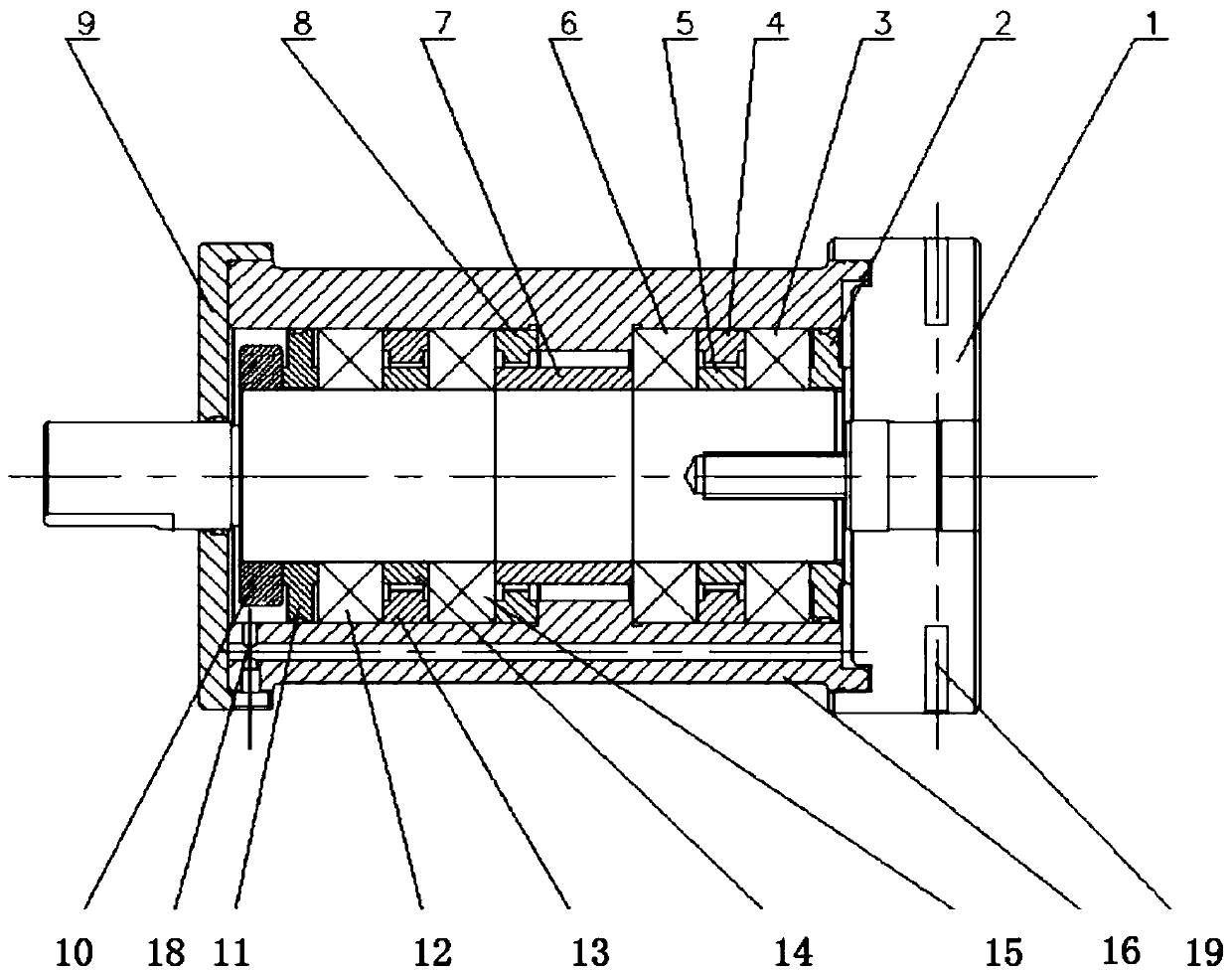

[0012] High-speed precision rotary shafts with high air pressure seals, such as figure 1 As shown, it mainly consists of shaft core (coarse grinding wheel shaft core) 1, rotating shaft cover 16, first angular contact ball bearing 12, second angular contact ball bearing 15, third angular contact ball bearing 6, fourth angular contact ball bearing 3 , Symmetrical structure band locking groove round nut 10 etc. composition. The specific structure is as follows: the outer ring on the left side of the third angular contact ball bearing 6 uses the shaft shoulder in the rotating shaft housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com