A Branched Film Hole Structure for Gas Turbine Engine Cooling

A technology of engine cooling and gas turbine, which is applied in the direction of engine cooling, turbine/propulsion device cooling, engine function, etc., which can solve the problems of weak cooling coverage effect and large cooling air consumption, etc., to increase coverage and process Low cost, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Structure, principle and performance of the present invention are described below in conjunction with accompanying drawing:

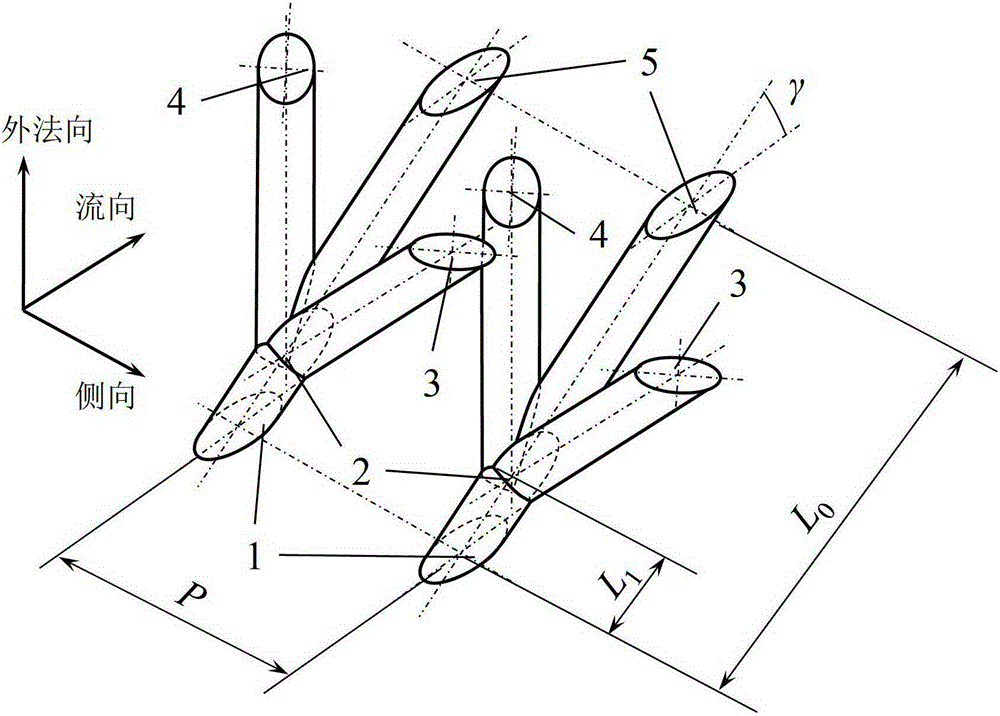

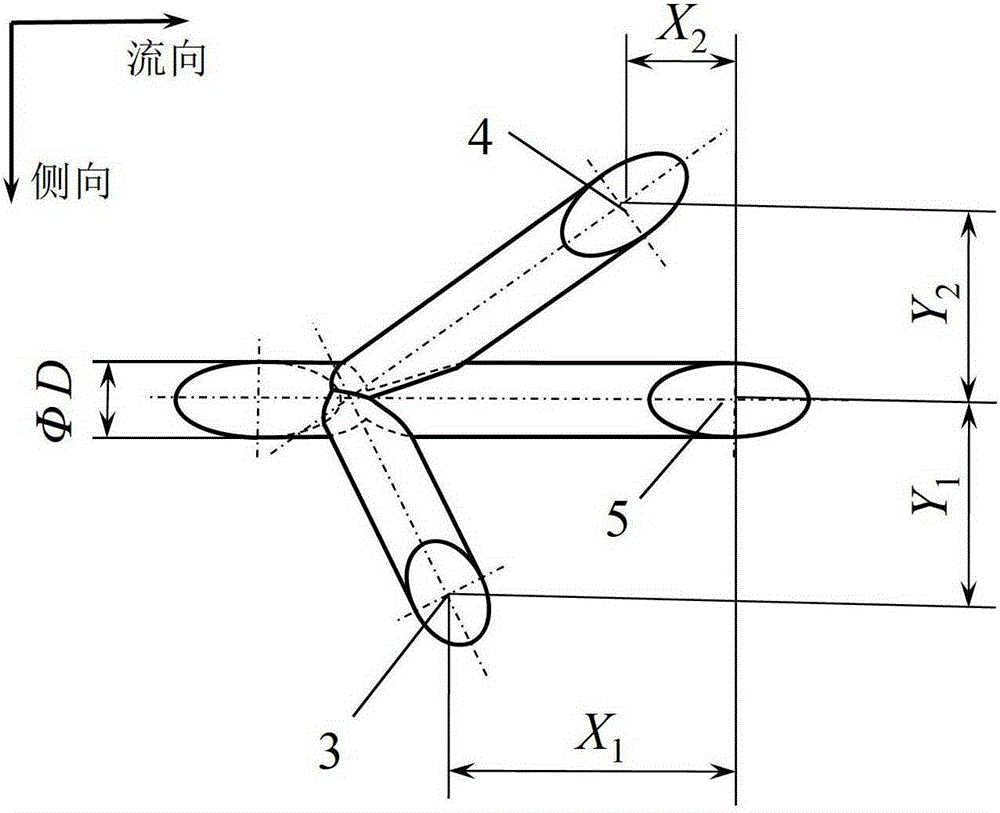

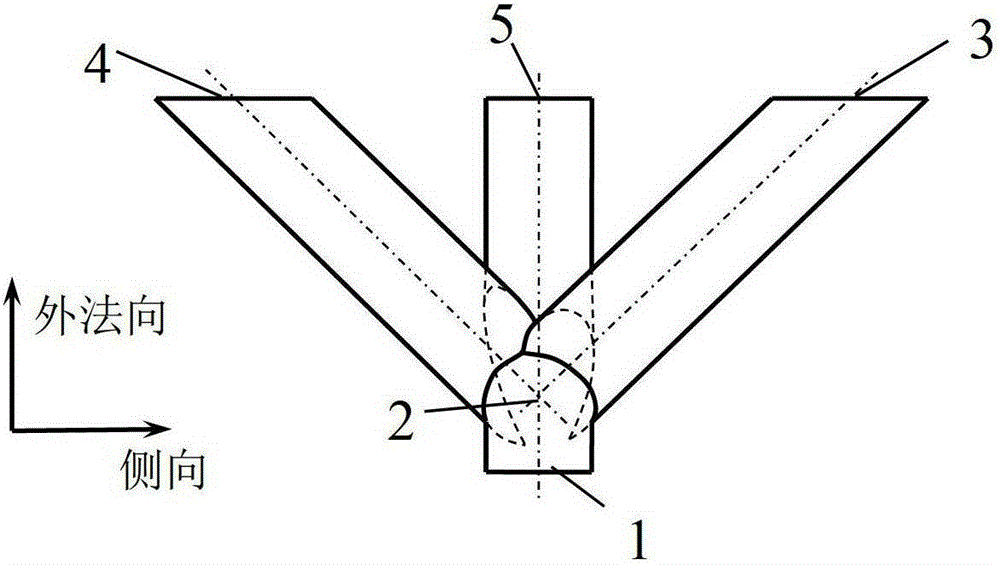

[0018] The present invention is a kind of branch gas film hole structure that is used for the cooling of gas turbine engine, and the basic geometrical feature of its through-flow part is as follows: figure 1 , figure 2 and image 3 shown. The basic geometric structure of the branch film cooling includes the main hole entrance 1, the bifurcation position 2, the first branch hole 3, the second branch hole 4 and the main hole outlet 5; the branch film holes are arranged in rows to form a film hole row structure The main hole is a straight hole with a circular cross-section; the first branch hole outlet 3 and the second branch hole outlet 4 are respectively connected to the gas film hole bifurcation position 2 through a circular cross-section straight hole; the main hole outlet 5, the first branch hole outlet 3 and the second branch hole outlet 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com