The control system of full digital single pulse electroplating power supply

An all-digital, control system technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of low precision, limited range of parameter setting, and increased product cost, and achieve high flatness of square wave waveform and circuit structure Simple and reliable, good output waveform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. However, the examples given are not intended to limit the present invention.

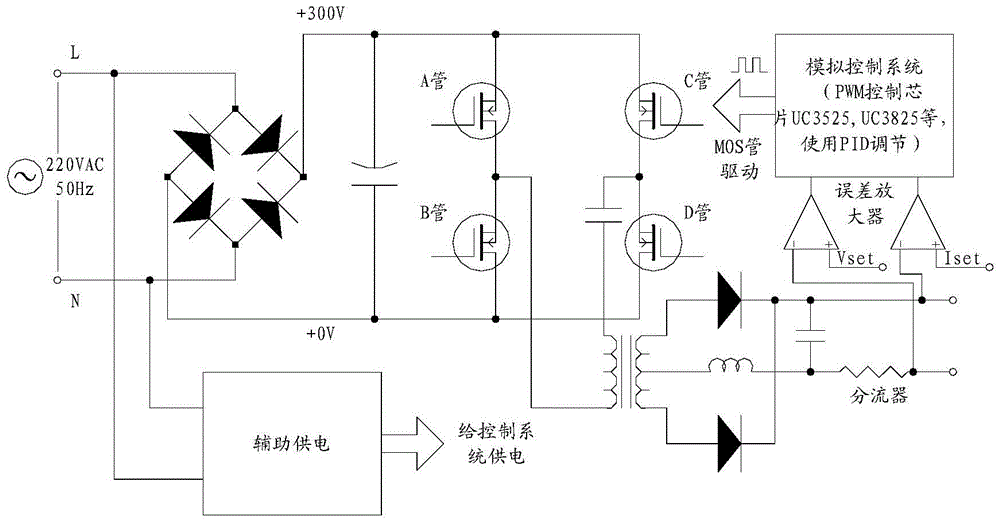

[0020] Such as Figure 5 As shown, the present invention provides a schematic structural diagram of a control system for an all-digital single-pulse electroplating power supply, including an EEROM 102 connected to a digital signal processing module 101 for storing power supply operating parameters and saving control parameters when power-off, a power board, and a secondary Level temperature detection and protection module 103, communication port 104 for completing communication, analog amplifier 105 for amplifying feedback voltage and telecommunication signal, PWM signal driving transformer 106, and power supply status indicator light and buzzer Display module 107 .

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com