An arc extinguishing method for magnetron sputtering process

A magnetron sputtering and arc technology, applied in the field of surface engineering, can solve the problems of high shutdown rate, low speed and efficiency of arc detection and extinguishment, etc., to reduce the number of shutdowns, improve arc detection rate, and fast detection and extinguishment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

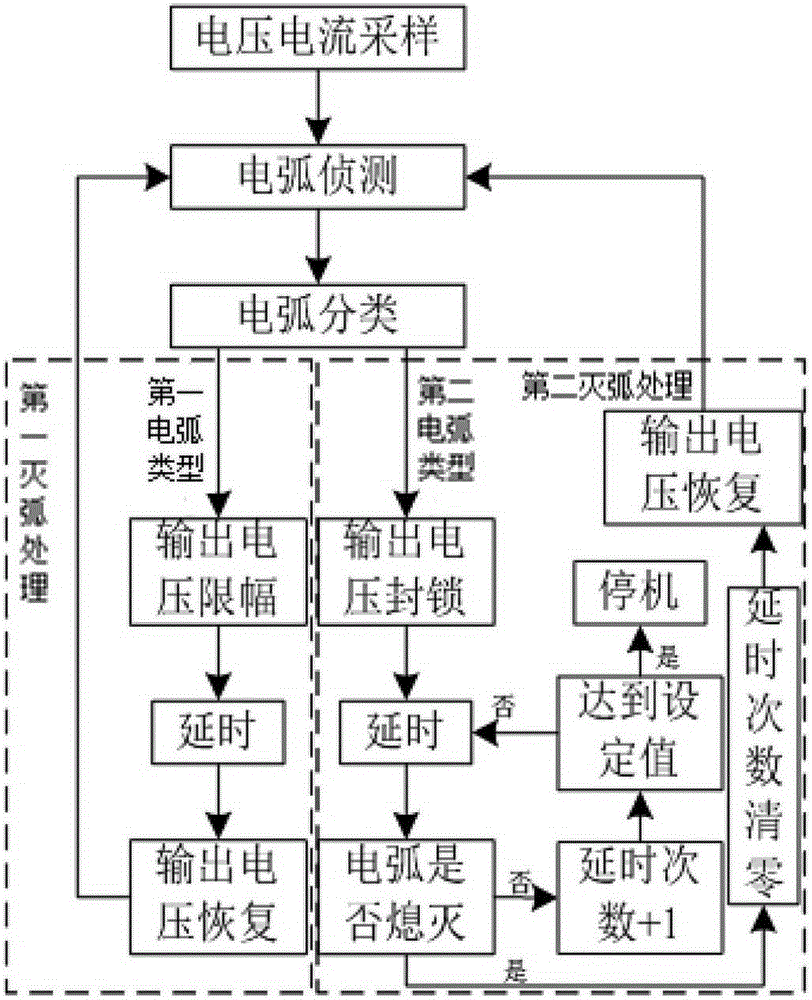

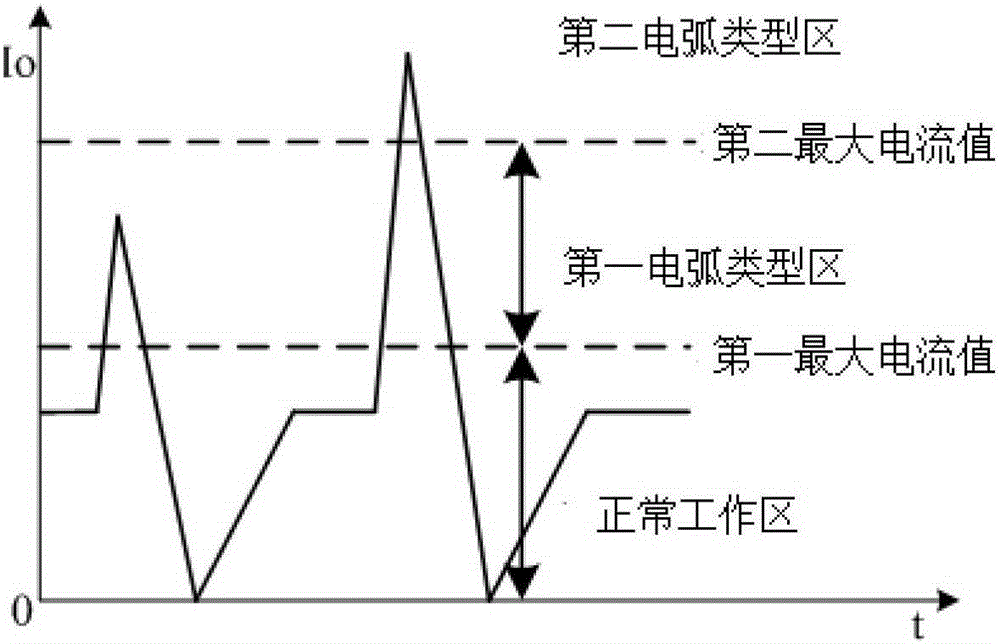

[0027] The present invention provides an arc extinguishing method for a magnetron sputtering process, such as figure 1 shown, follow the steps below:

[0028] Step 1: Use the voltage and current Hall sensors to collect the output voltage and current of the magnetron sputtering power supply, and use the current amplitude and the voltage drop rate as the judgment basis to carry out arc detection, which is specifically implemented according to the following steps: using the voltage detection method and the current The detection method detects the arc at the same time. As long as there is one method to detect the arc first, the arc is considered to be generated.

[0029] Among them, the voltage detection method is specifically implemented according to the following steps: in the magnetron sputtering power supply controller, the continuously collected voltage values are calculated, that is, the current collected voltage value is compared with the previous collected voltage value....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com