Quick-opening manhole

A technology for quickly opening manholes and manhole covers, which is applied in biochemical instruments, biochemical equipment and methods, enzymology/microbiology devices, etc. Problems such as collision head or manhole takeover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

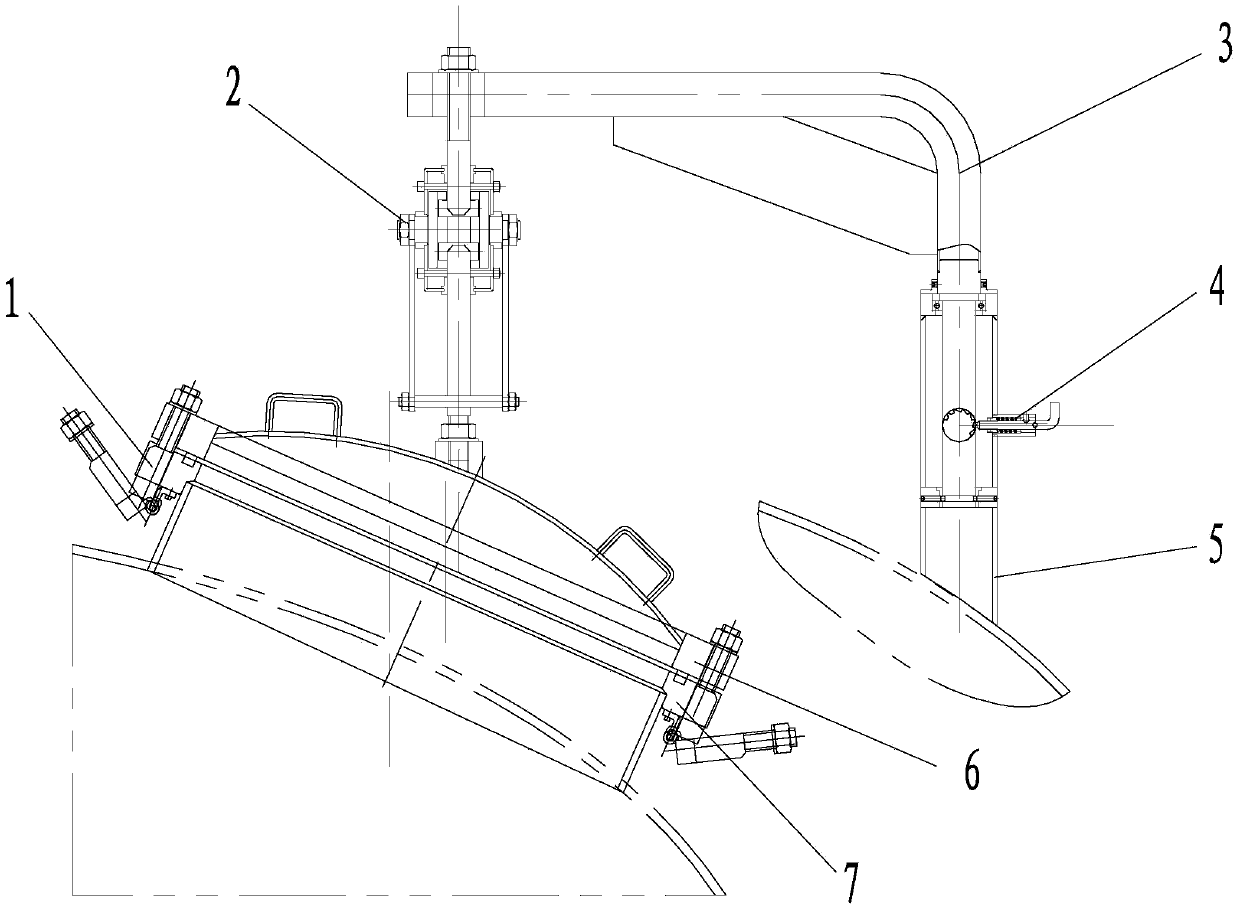

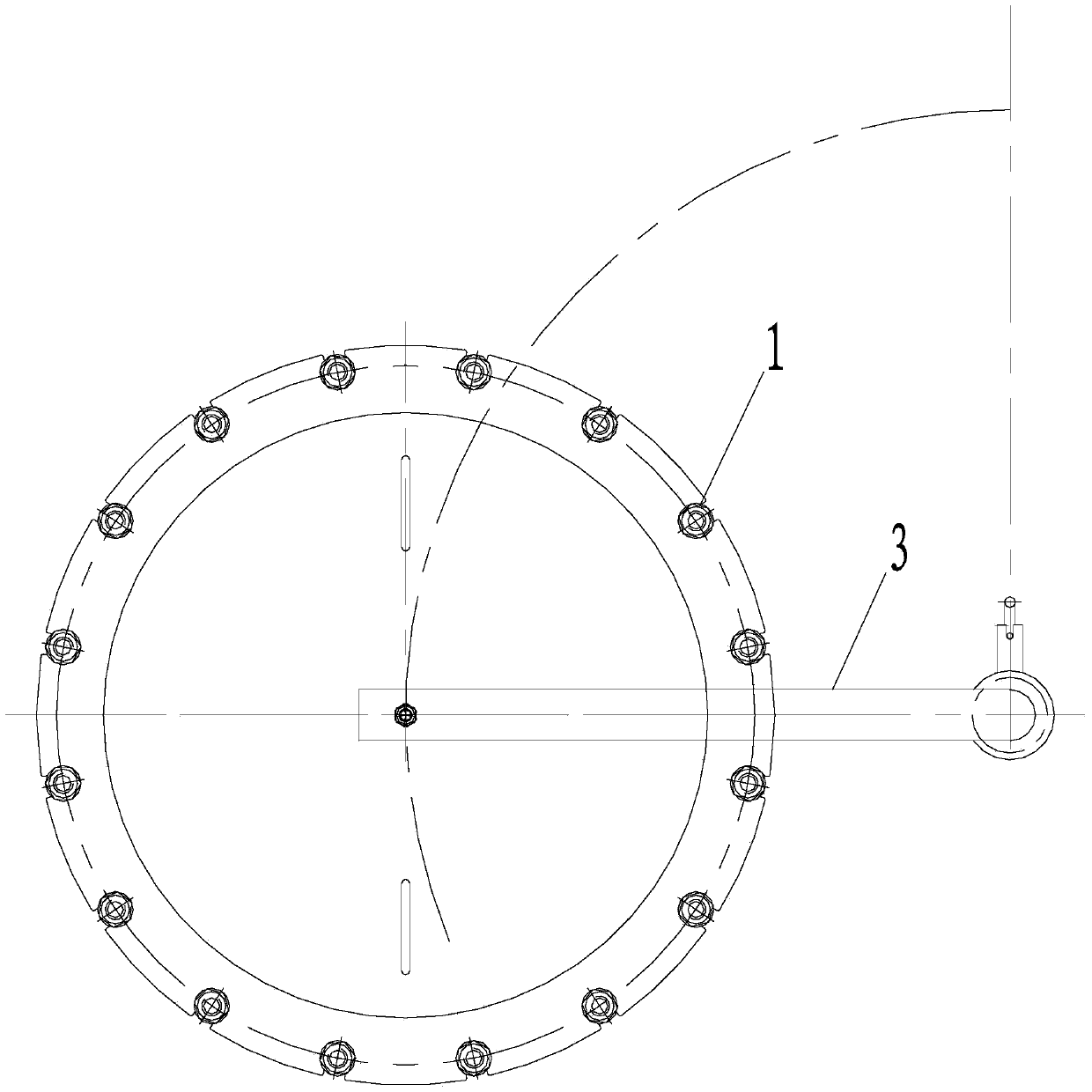

[0025] Such as figure 1 As shown, the present invention discloses a quick-opening manhole, comprising a manhole, a manhole cover, a manhole cover lifting device 2, a slewing boom 3, a slewing boom fixing seat 5, a flip locking bolt 1, and a manhole cover. On the manhole, one end of the manhole cover lifting device 2 is connected with the manhole cover, and the other end is connected with the manhole cover rotary boom 3, the rotary boom 3 is arranged on the rotary boom fixing seat 5, and the manhole is provided Manhole flange 7 is provided with manhole cover flange 6 on the manhole cover. The rotary boom 3 is provided with a rotary boom locking device 4 . Lock the rotary boom locking device 4 while the manhole cover is locked. When the manhole cover needs to be opened, open the rotary boom locking device 4, and lock the rotary crane again when the manhole cover is moved to a suitable position. Arm locking device 4.

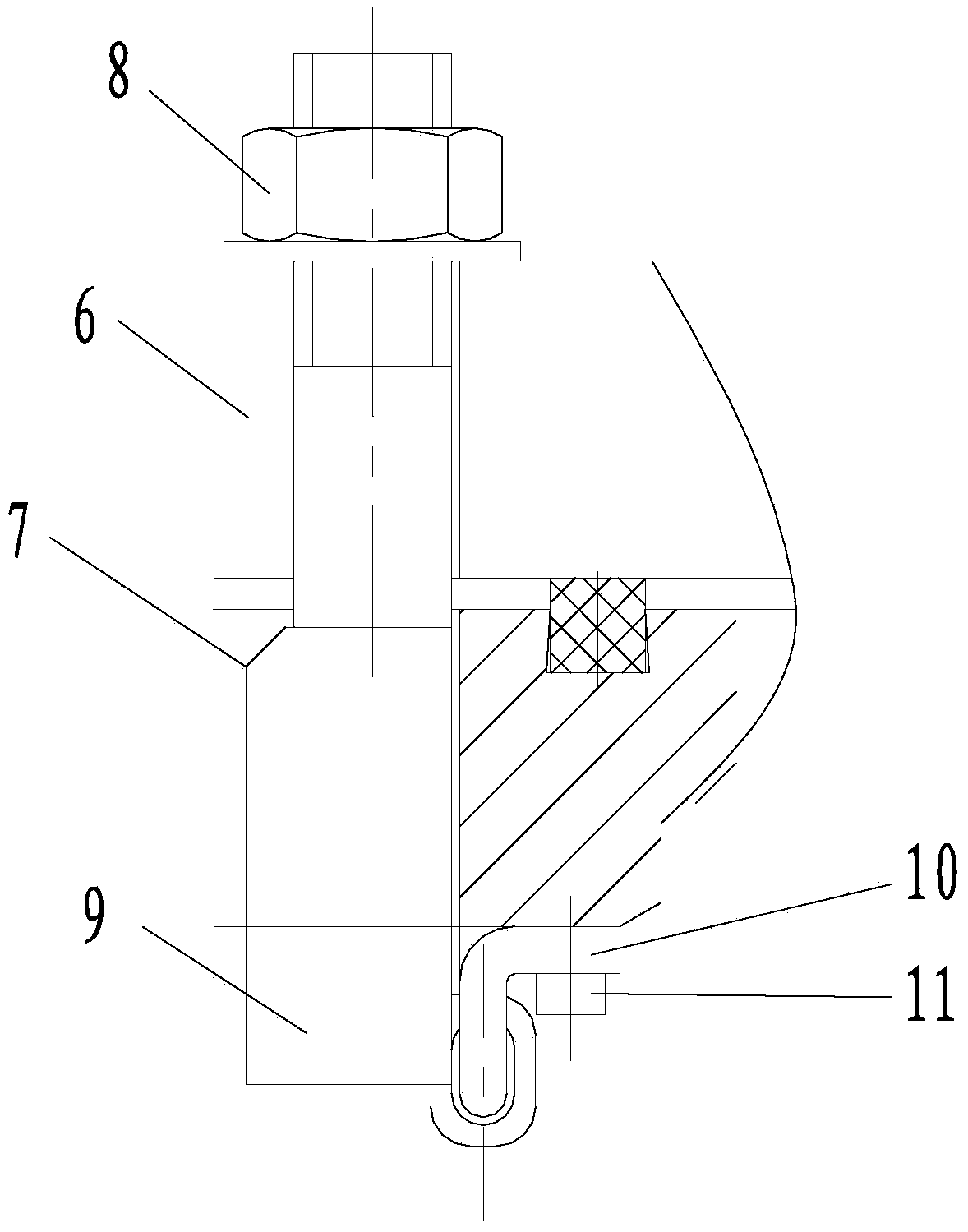

[0026] Such as Figure 2-5 As shown, the overturning lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com