Preparation method of cordyceps sinensis wine

A kind of Cordyceps sinensis wine and the technology of Cordyceps sinensis, which is applied in the field of preparation of Cordyceps sinensis wine, can solve the problems of easy precipitation, high cost and complicated process of Cordyceps sinensis wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

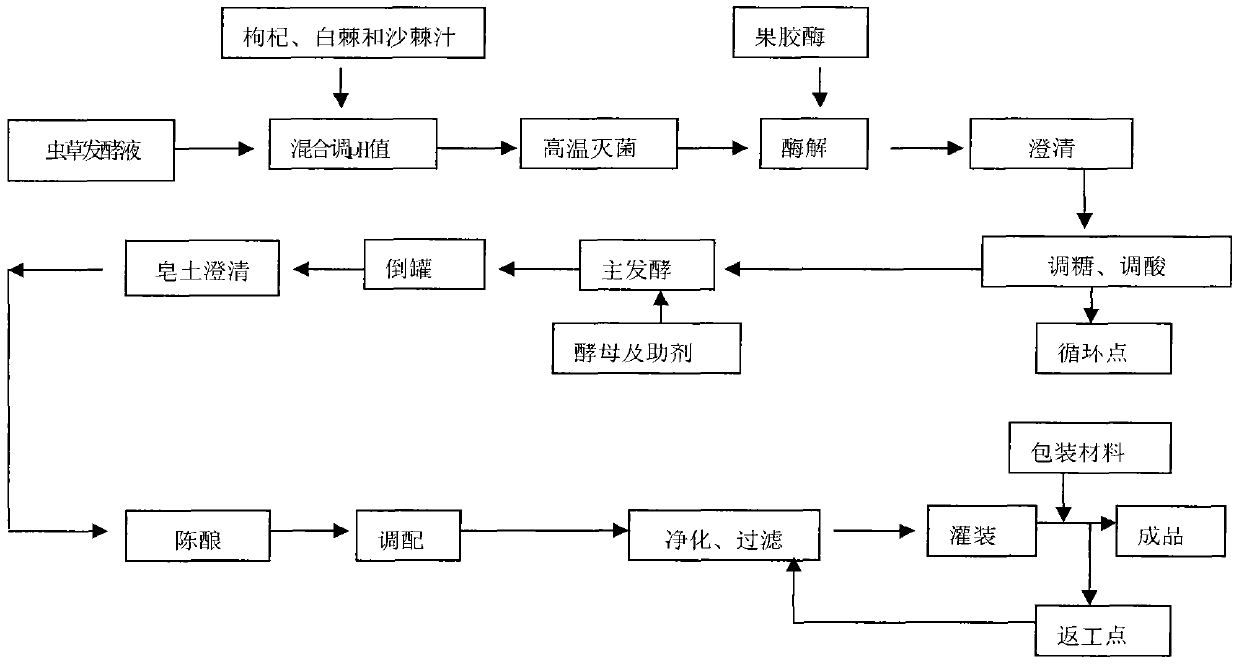

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of embodiment 1 Cordyceps sinensis wine, as follows:

[0033] A. Degrease wolfberry, white buckthorn and sea buckthorn, squeeze the juice for later use;

[0034] B. Take Cordyceps sinensis fermented liquid, add defatted wolfberry, white buckthorn, seabuckthorn juice, add pH regulator, make the pH of the raw material to be fermented 3.8;

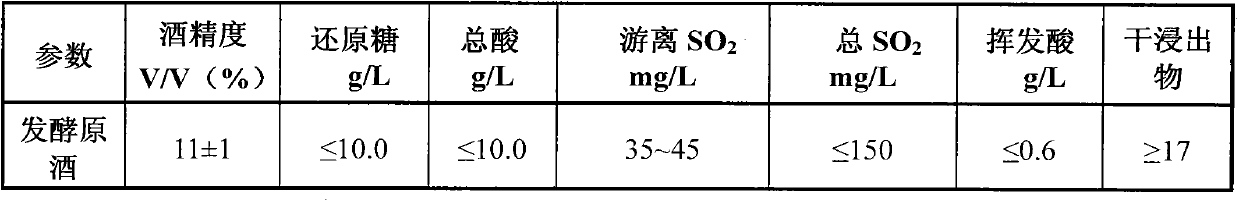

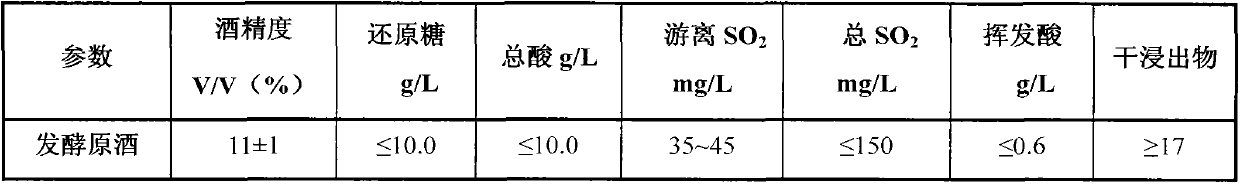

[0035] C. The raw material to be fermented with adjusted pH is coarsely filtered with stainless steel mesh cloth once before entering the tank, and then heated to the optimum temperature for enzymolysis through the blending tank, and then input into the clarification tank through a special pipeline; the total acid is measured when entering the tank , uniformly adjust the total acid ≤ 15g / L; use food-grade sulfurous acid to evenly add in batches when the raw materials to be fermented are put into the tank, so that the free sulfur dioxide is 60-80mg / L;

[0036] E. adding pectinase to carry out enzymolysis in...

Embodiment 2

[0058] A kind of preparation method of embodiment 2 Cordyceps sinensis wine, as follows:

[0059] A. Degrease wolfberry, white buckthorn and sea buckthorn, squeeze the juice for later use;

[0060] B. Take Cordyceps sinensis fermented liquid, add defatted wolfberry, white buckthorn, seabuckthorn juice, add pH regulator, make the pH of the raw material to be fermented 3.5;

[0061] C. The raw material to be fermented with adjusted pH is coarsely filtered with stainless steel mesh cloth once before entering the tank, and then heated to the optimum temperature for enzymolysis through the blending tank, and then input into the clarification tank through a special pipeline; the total acid is measured when entering the tank , uniformly adjust the total acid ≤ 15g / L; use food-grade sulfurous acid to evenly add in batches when the raw materials to be fermented are put into the tank, so that the free sulfur dioxide is 60-80mg / L;

[0062] E. adding pectinase to carry out enzymolysis in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com