Technique for preparing derived fuel from municipal sludge and biomass

A technology of derived fuel and biomass raw material, which is applied in the field of municipal sludge and biomass treatment, can solve the problems of restricting industrialization development, long process flow, complicated equipment, etc., to prolong the service life, shorten the process flow, and reduce the difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

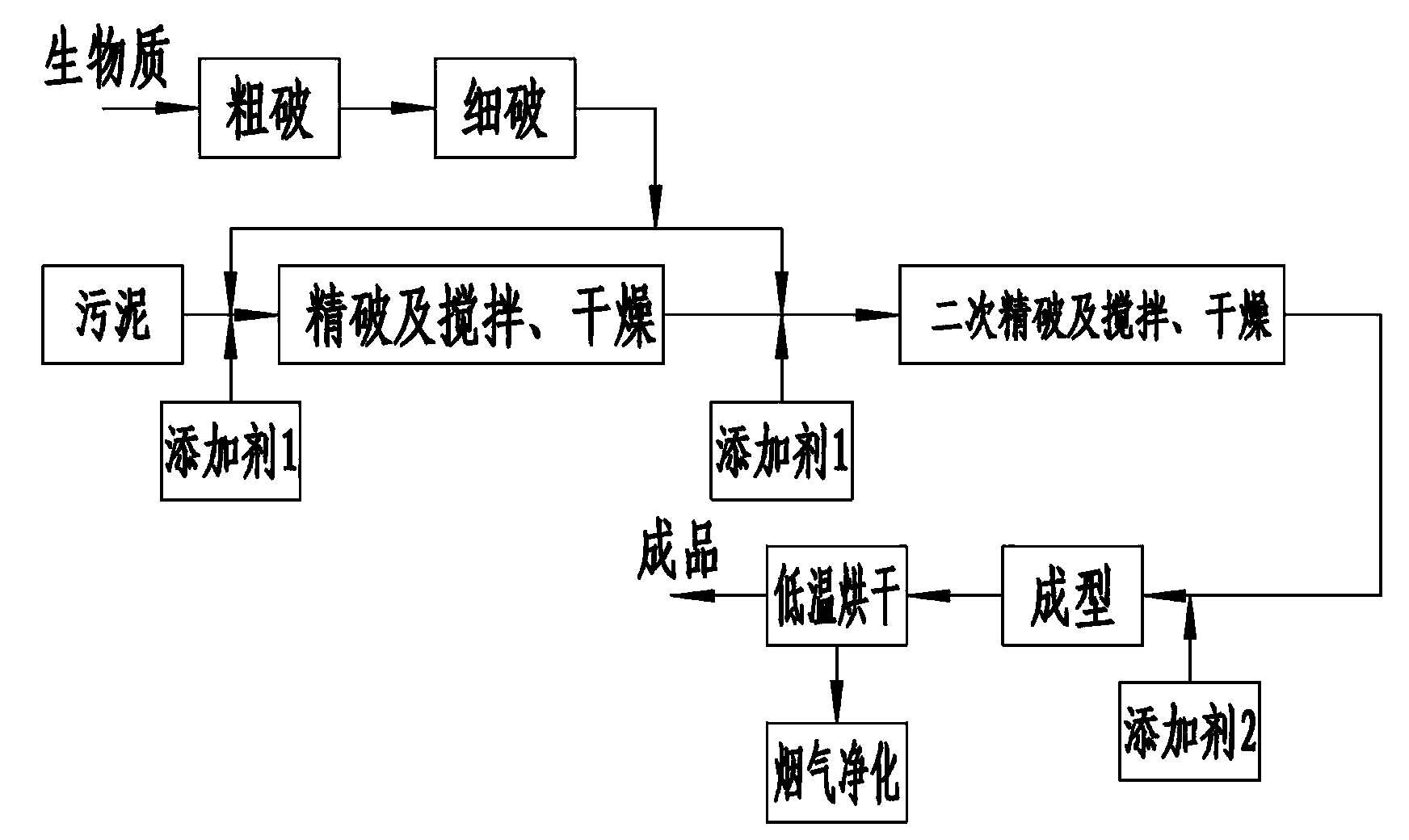

[0037] A process for preparing derived fuel from high-humidity municipal sludge and biomass, comprising the following steps:

[0038] (1) Biomass coarse crushing process: the biomass raw material is coarsely crushed with a crusher.

[0039] The biomass raw materials are mainly fast-growing bamboo, plant stalks, branches, roots and the like.

[0040] The coarse crusher is the SSI-M50E crusher from SSI Company of the United States. The rotating speed is 26r / min; the thickness of the crushing tool is 50mm. The crushing capacity is 15T / H.

[0041] (2) Biomass fine crushing process: use a crusher to send the biomass raw materials from the previous process for fine crushing.

[0042] After crushing in this process, 90% of the biomass raw materials are below 15mm×10mm in size.

[0043] The fine crusher is the SSI-M50E crusher from SSI Company of the United States. The rotating speed is 26r / min; the thickness of the crushing tool is 15mm. The crushing capacity is 10T / H.

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com