A kind of ultra-mirror anti-scratch transfer film and preparation method thereof

A technology of ultra-mirror surface and transfer film, which is applied in the field of transfer film, can solve the problems of poor scratch resistance of leather transfer film, difficulty in meeting decoration requirements, and weak mirror effect, etc., to achieve improved scratch resistance and mirror effect, good decorative effect, The effect of excellent slitting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

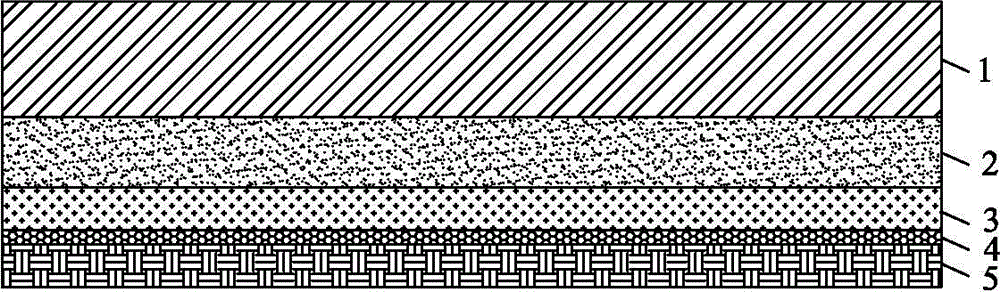

[0037] A super-mirror anti-scratch transfer film of the present embodiment comprises the following preparation steps:

[0038] a, get the base film layer 1, the base film layer 1 is a PET film;

[0039] B, the water-based polyurethane that is 50 parts by weight, the methyl alcohol of 10 parts and the water of 10 parts are mixed and stirred evenly, is modulated into water-based release coating, and the viscosity of water-based release coating is 30cps;

[0040] C, the water-based release coating prepared in the step b is dropped into the first coating trough of the coating machine, utilizes the first coating roller to coat the water-based release coating on the surface of the PET film, the first coating roller The coating speed is 30m / min to form a water-based release coating;

[0041] d. The PET film coated with water-based release coating is transported to the drying device for drying treatment. After the water-based release coating is dried, it becomes the water-based relea...

Embodiment 2

[0045] A super-mirror anti-scratch transfer film of the present embodiment comprises the following preparation steps:

[0046] a, get the base film layer 1, the base film layer 1 is a PET film;

[0047] B, the water-based polyurethane that is 60 parts by weight, the methyl alcohol of 20 parts and the water of 20 parts are mixed and stirred evenly, is modulated into water-based release coating, and the viscosity of water-based release coating is 26cps;

[0048] C, the water-based release coating prepared in the step b is dropped into the first coating trough of the coating machine, utilizes the first coating roller to coat the water-based release coating on the surface of the PET film, the first coating roller The coating speed is 60m / min to form a water-based release coating;

[0049] d. The PET film coated with water-based release coating is transported to the drying device for drying treatment. After the water-based release coating is dried, it becomes the water-based relea...

Embodiment 3

[0053] A super-mirror anti-scratch transfer film of the present embodiment comprises the following preparation steps:

[0054] a, get the base film layer 1, the base film layer 1 is a PET film;

[0055] B, the water-based polyurethane that is 70 parts by weight, the isopropanol of 30 parts and the water of 30 parts are mixed and stirred evenly, is modulated into water-based release coating, and the viscosity of water-based release coating is 20cps;

[0056] C, the water-based release coating prepared in the step b is dropped into the first coating trough of the coating machine, utilizes the first coating roller to coat the water-based release coating on the surface of the PET film, the first coating roller The coating speed is 100m / min to form a water-based release coating;

[0057] d. The PET film coated with water-based release coating is transported to the drying device for drying treatment. After the water-based release coating is dried, it becomes the water-based release...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com