Adjustable heat shrink tube limit heating and sizing device

A technology for heating and sizing and heat-shrinking tubes is applied in the field of adjustable heat-shrinkable tube limit heating and sizing devices, which can solve the problems of low production efficiency, high labor intensity of workers, low efficiency, etc., to ensure consistency and solve stability problems. , the effect of improving labor efficiency and thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

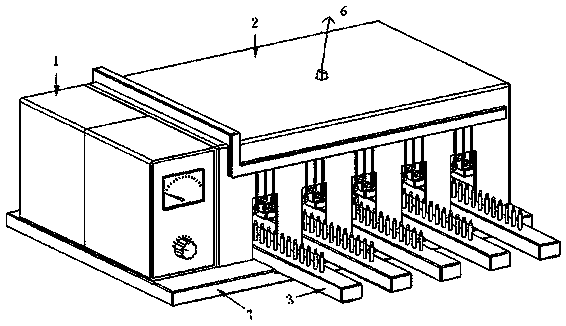

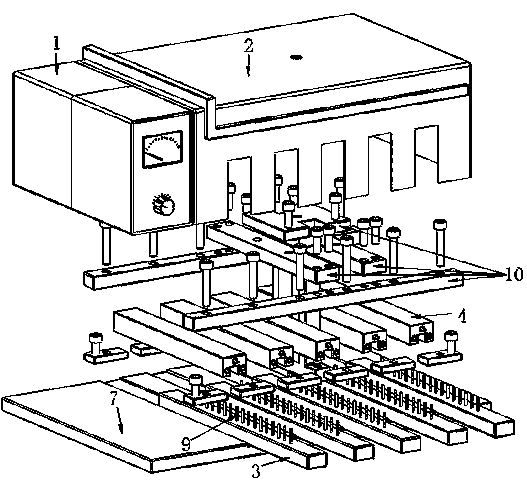

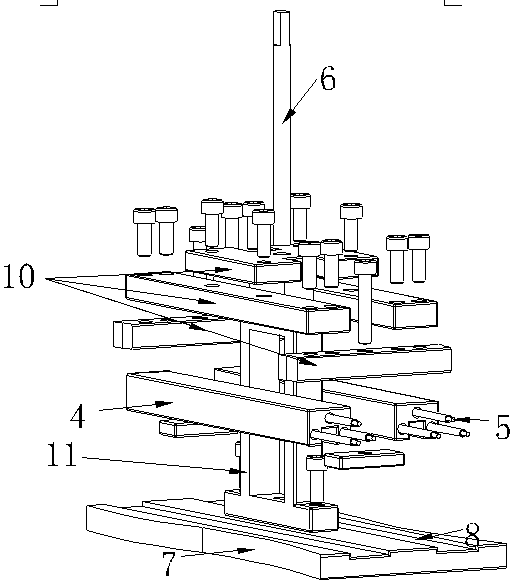

[0024] An adjustable heat-shrinkable tube limit heating and shaping device, which is composed of a limit heating furnace and a limit setting fixture. The limit heating furnace includes a temperature controller 1, a furnace box cover 2, an operating rod 3, a furnace 4, and an electric heater. Rod 5 and furnace bottom 7, the furnace box cover 2 is covered on the furnace bottom 7, the temperature controller 1 is connected to the electric heating rod 5, and is located on the side of the furnace box cover 2, and the furnace bottom 7 is vertically There are 5 furnace guide grooves 8, the furnace support 10 is connected with the height adjustment support 11, the height of the furnace support 10 can be adjusted by the height adjustment screw 6, and the bottom of the horizontally arranged furnace support is connected with 5 furnaces 4, and the furnace 4 is connected with the furnace guide. The positions of the grooves 8 correspond one by one, the furnace 4 is a "U"-shaped groove with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com