Desulfurization and denitrification system and method

A technology for desulfurization and denitrification, flue gas, applied in the field of desulfurization and denitrification systems, can solve the problems of strict management and maintenance requirements, short survival time of oxidative free radicals, and low activity of hydrogen peroxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

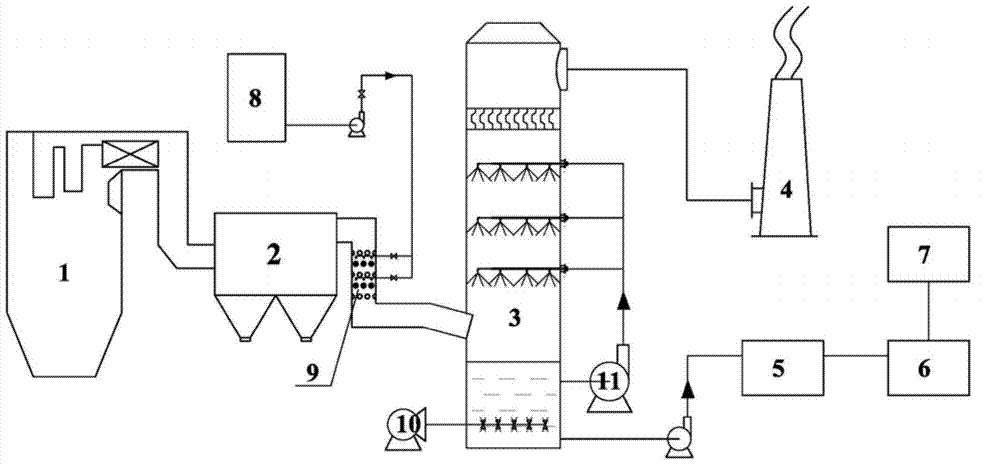

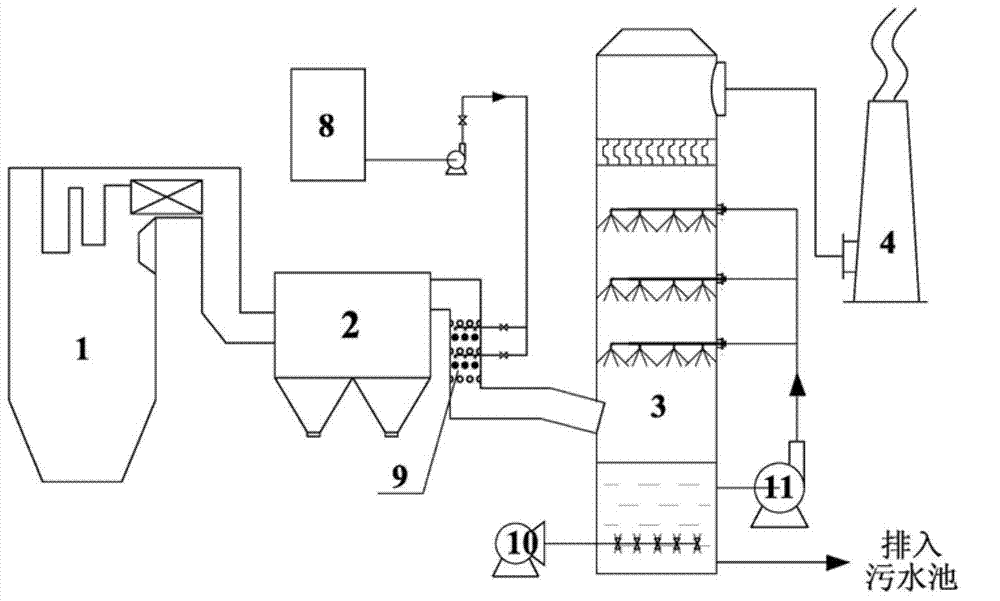

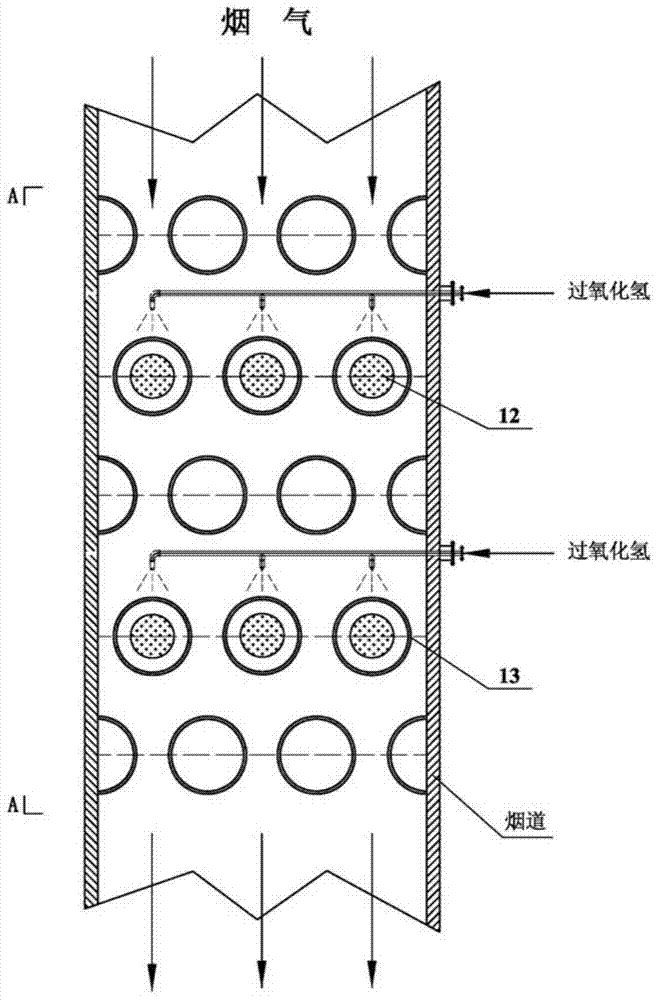

[0047] The desulfurization and denitrification system described in this embodiment is as follows: figure 2 As shown, the flue gas generating device 1 is a boiler, and the absorption tower 3 is a spray tower with a diameter of 1.2m and a height of 18m; the hydrogen peroxide pyrolysis system 9 is arranged on the flue between the dust collector 2 and the absorption tower 3, The pipe fittings are circular pipes, and the Venturi member is set with 5 layers, such as image 3 As shown, a thermocouple is used to heat the even-numbered layer pipe. When the flue gas is desulfurized and denitrified, the heating device is used to heat the even-numbered pipe fittings of the gas mixing device to a temperature of 500°C; the hydrogen peroxide solution in the hydrogen peroxide storage tank is metered and extracted and sprayed to the heated pipe through the atomizing nozzle On the surface, the injection amount of hydrogen peroxide is 1.36 times the number of moles of nitrogen oxides, so that ...

Embodiment 2

[0050] The flue gas simultaneous desulfurization and denitrification system based on the action of hydrogen peroxide is the same as Example 1, except that the surface temperature of even-numbered layer pipe fittings is 490°C. Use Test350 flue gas analyzer to measure flue gas composition: SO in flue gas generated by flue gas generating device 2 345ppm, NO x is 172ppm; after desulfurization and denitrification, the SO in the flue gas at the outlet of the absorption tower 2 2ppm, NO 16ppm, NO x is 33ppm.

Embodiment 3

[0052] The flue gas simultaneous desulfurization and denitrification system based on the action of hydrogen peroxide is the same as Example 1, except that the injection amount of hydrogen peroxide is 1.1 times the molar number of nitrogen oxides. Measure flue gas composition with Test350 flue gas analyzer: SO in flue gas generated by flue gas generating device 2 365ppm, NO x is 168ppm; SO in the flue gas at the outlet of the absorption tower after desulfurization and denitrification 2 2ppm, NO 12ppm, NO x is 28ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com