Reaction solution viscosity detection method, reaction solution viscosity detection device, method for obtaining reaction product, and manufacturing device for obtaining reaction product

A technology of reaction products and reaction liquids, applied in the field of manufacturing equipment for obtaining reaction products, can solve problems such as difficulty in popularization, long delivery time, and increased installation costs of viscometers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

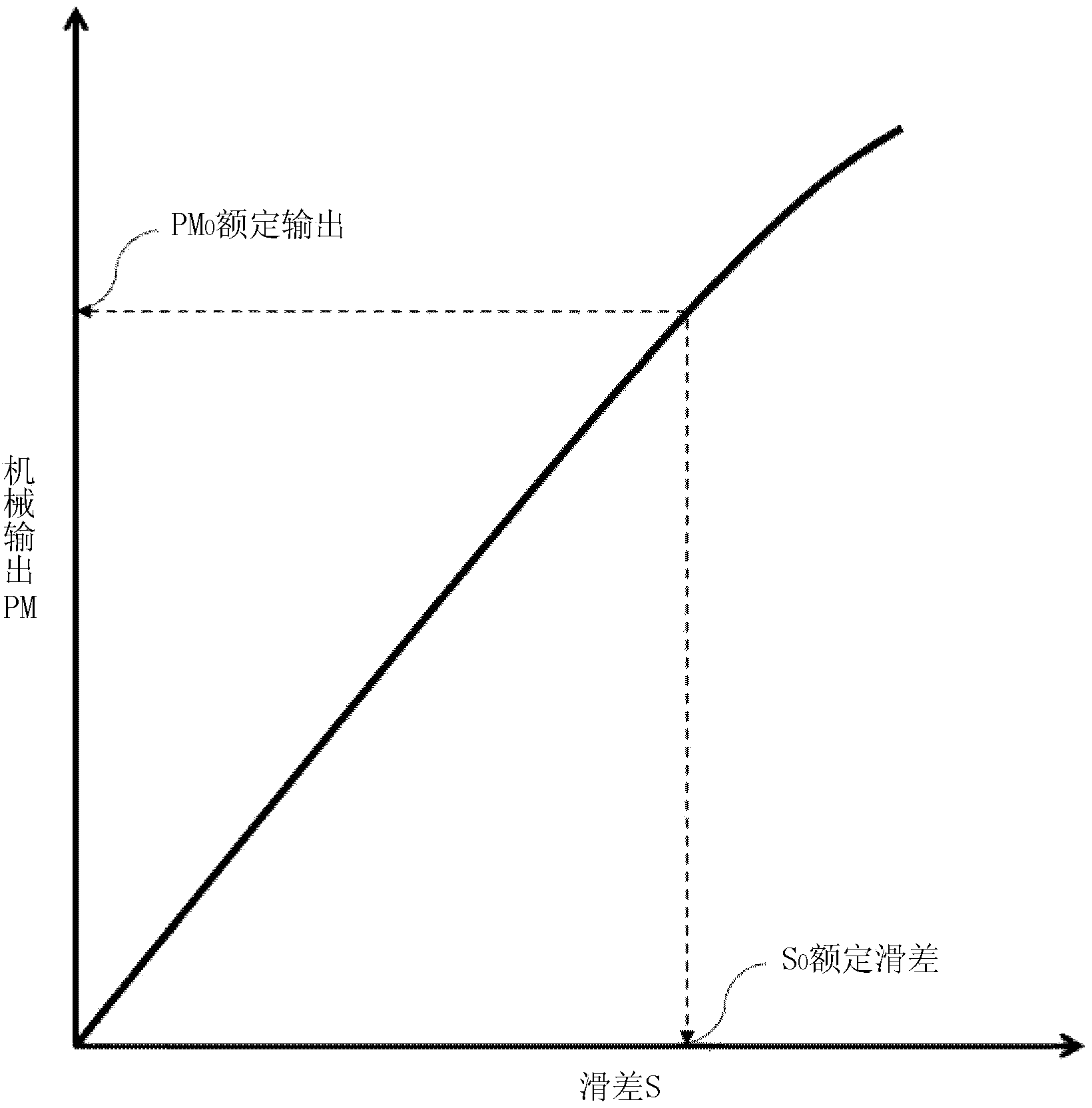

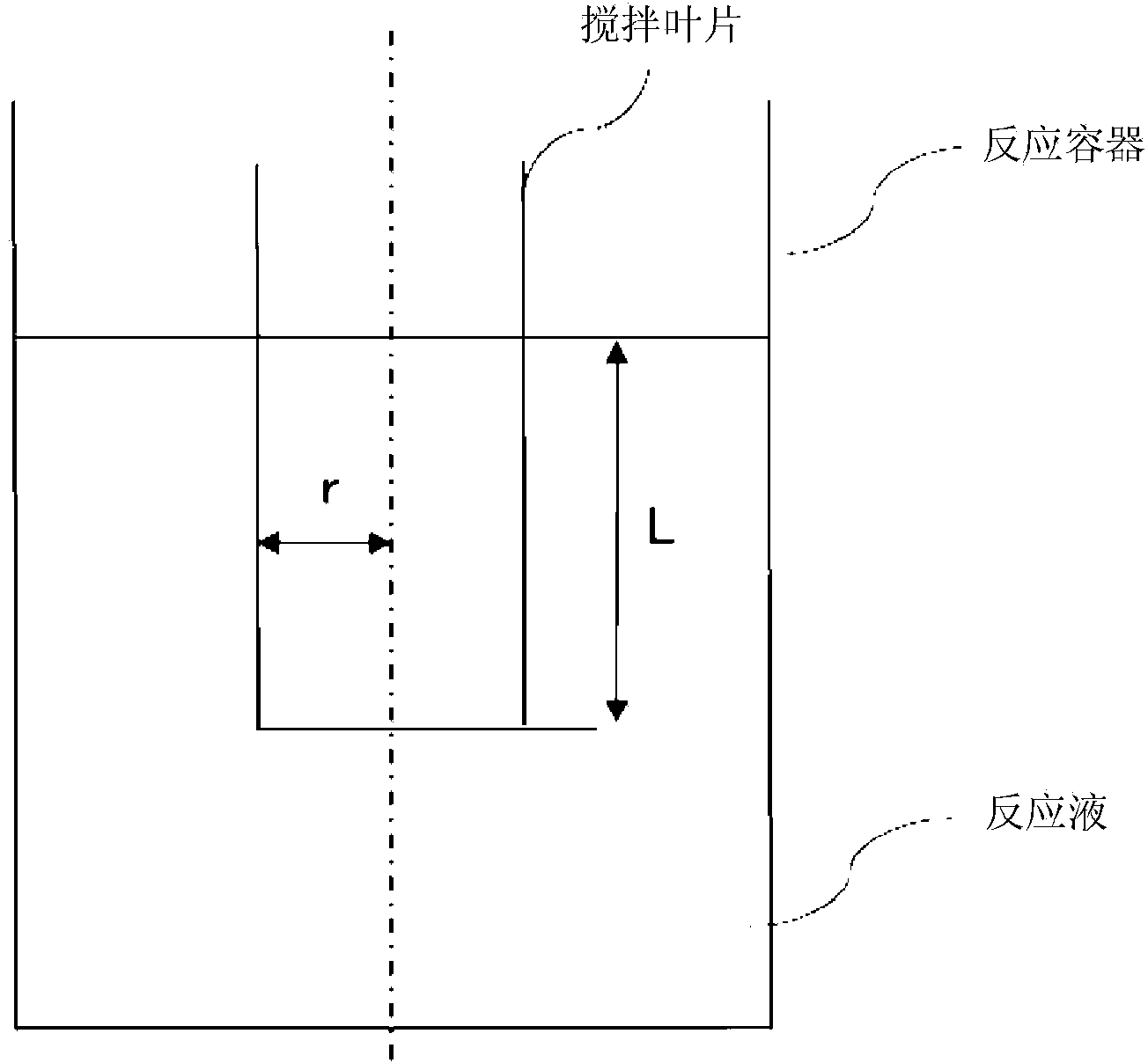

Method used

Image

Examples

Embodiment

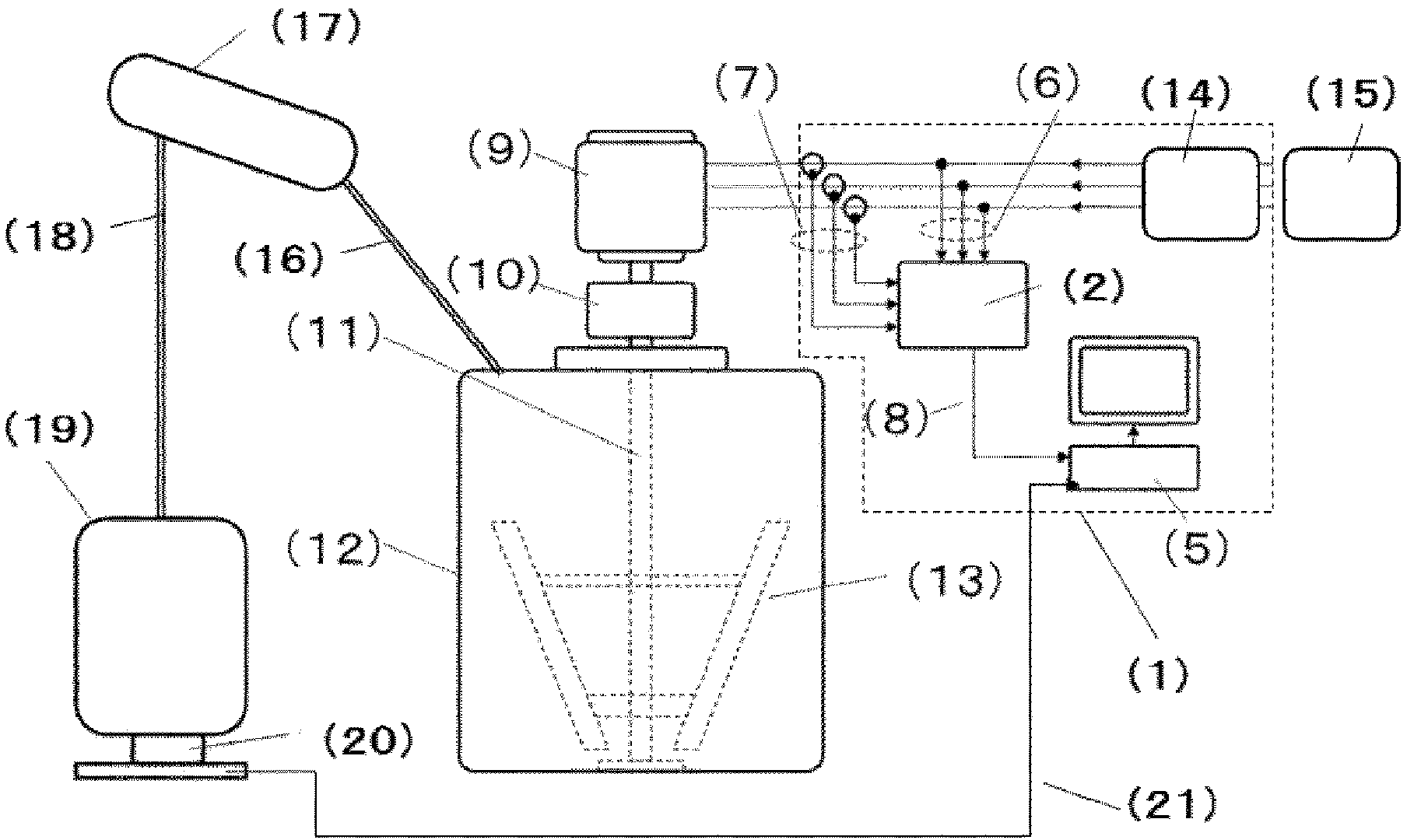

[0215] An example in which the present invention is applied to the production of a reaction solution containing a phenolic resin will be described below. Among them, used in the manufacture of this reaction solution image 3 device shown. The specifications of the induction motor 9 are as follows.

[0216] Specifications of three-phase induction motor (Y connection line)

[0217] Capacity: 15kW Rated speed: 1460 revolutions per minute (rated slip 0.0266)

[0218] Rated voltage: 200V Rated current: 57A Rated frequency: 50Hz

[0219] Number of poles: 4

[0220] Primary coil resistance: 0.0943Ω

[0221] Primary coil reactance: 0.725Ω (at rated frequency)

[0222] Secondary coil resistance: 0.0130Ω

[0223] Secondary coil reactance: 0.0320Ω (at rated frequency)

[0224] Resistance measurement standard temperature: 20°C Resistance temperature coefficient: 234.5

[0225] Mechanical loss: 70W (at rated speed)

[0226] Iron loss: 335W (design value: hysteresis loss 115W, edd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Iron loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com