Carbon fiber composite heating cable

A composite heating and carbon fiber technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of insulation layer, outer sheath oxidation, short service life of cable, large starting current load, etc., to achieve no electromagnetic radiation and operating costs. Low, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with the best embodiment 。

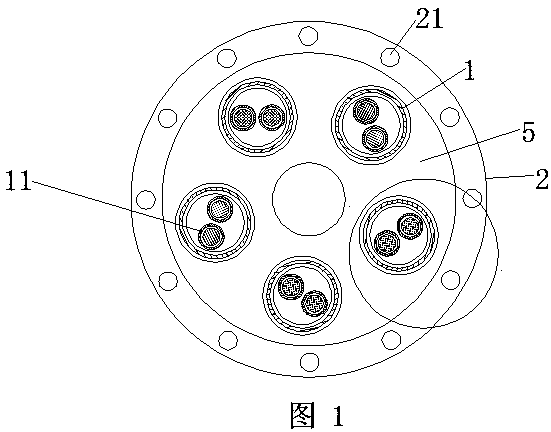

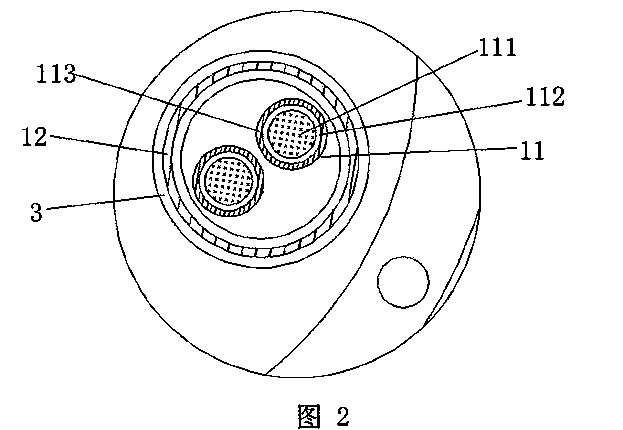

[0012] Such as figure 1 with figure 2 As shown, the present invention is a carbon fiber composite heating cable, which includes a carbon fiber core wire 1 and an epoxy resin rubber sheath 2. The carbon fiber core wire 1 includes two carbon fiber wires 11, and the carbon fiber wire 11 is provided with two layers of Teflon The high temperature resistant plastic layer 12, the carbon fiber core wire 1 is wrapped with a thermally conductive insulating layer 3; the epoxy resin rubber sheath 2 is provided with several carbon fiber core wires 1 arranged in a ring, and the epoxy resin rubber sheath 2 and The carbon fiber core wires 1 are filled with thermally conductive insulating paste 5 . The carbon fiber wire 11 includes a resin pre-impregnated carbon fiber stranded bundle 111 , the carbon fiber stranded bundle 111 is wrapped with a high temperature mica layer 112 , and the high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com