Smart card carrier tape manufacturing method

A manufacturing method and technology for smart cards, which are applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of polluting the environment and large consumption of materials, protect the environment, overcome the huge consumption of materials, reduce the consumption of metal materials and The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

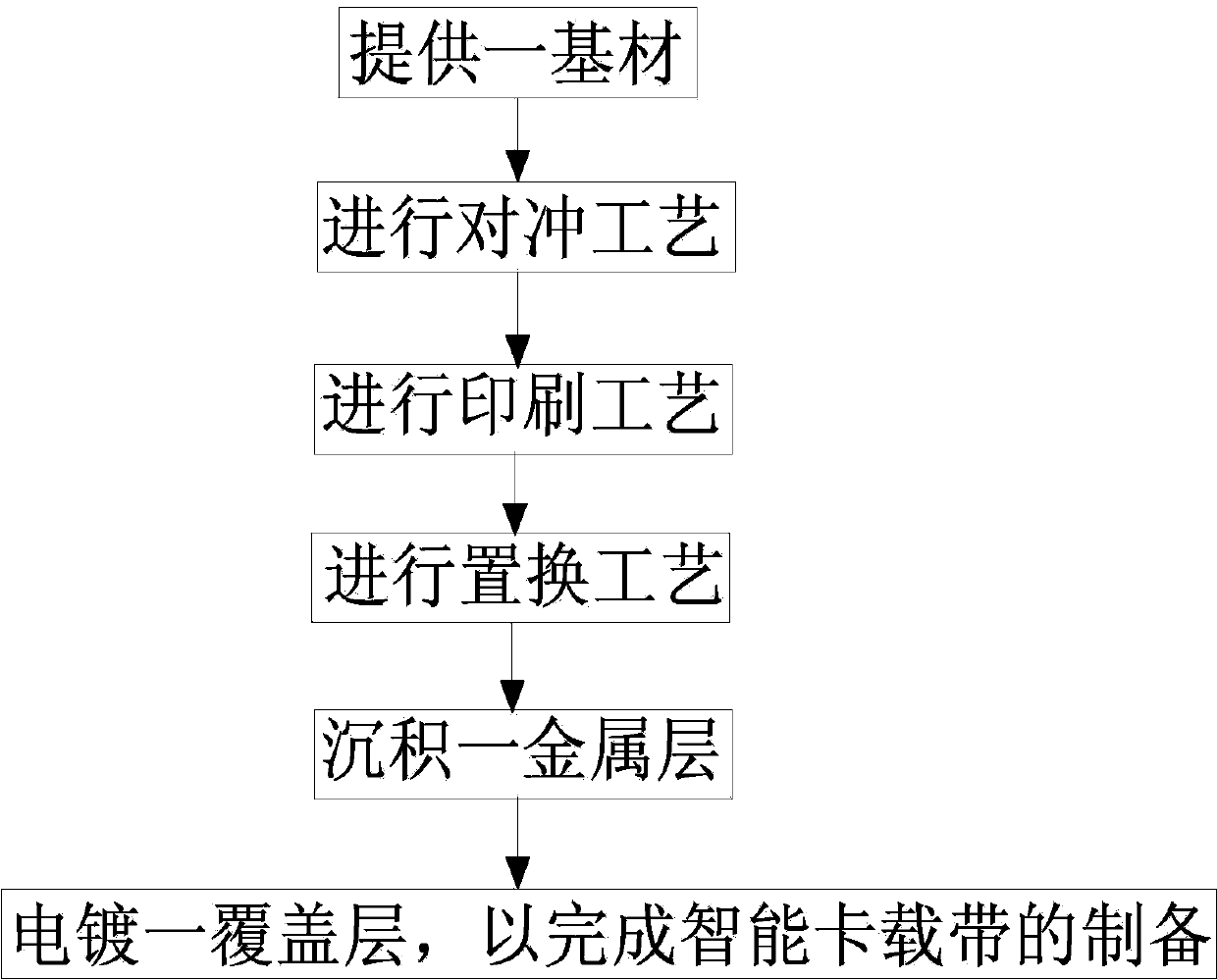

[0043] figure 1 It is a schematic flow chart of the manufacturing method of the smart card carrier tape provided by the embodiment 1 of the present invention; mixture, and the thickness of the substrate is 0.05mm-0.125mm, such as 0.05mm, 0.08mm, 0.10mm, 0.11mm, 0.12mm, 0.125mm, etc.

[0044] The base material provided above is subjected to a hedging process by means of mechanical drilling or laser drilling, so as to form alignment holes required by the process on the base material.

[0045]Then, the printing process is carried out on the substrate with the alignment holes formed. The printing process includes: printing the catalytic ink onto the above-mentioned alignment holes by using screen printing method, flexographic printing method, letterpress printing method or gravure printing method. On the base material, use hot air curing method or infrared curing method, and perform curing operation at a temperature of 130°C to 150°C, such as 130°C, 135°C, 140°C, 145°C, 150°C, et...

Embodiment 2

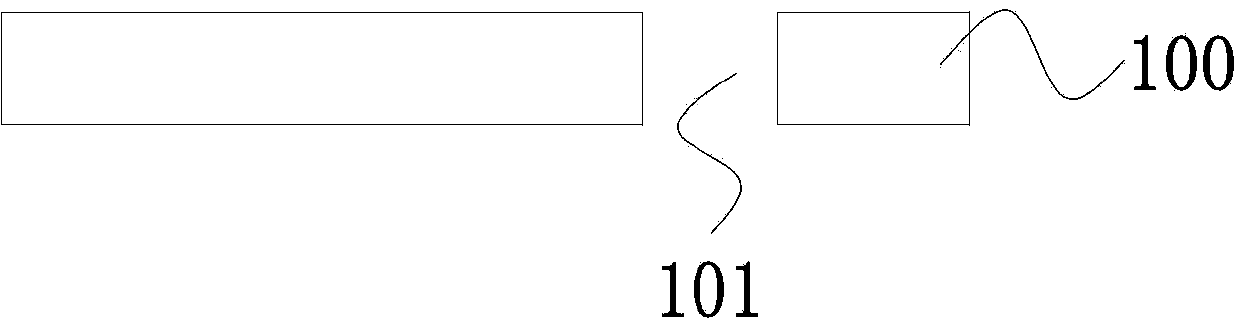

[0053] figure 2 It is a schematic diagram of the structure of the alignment hole formed on the substrate provided by Example 2 of the present invention; The required alignment hole 101.

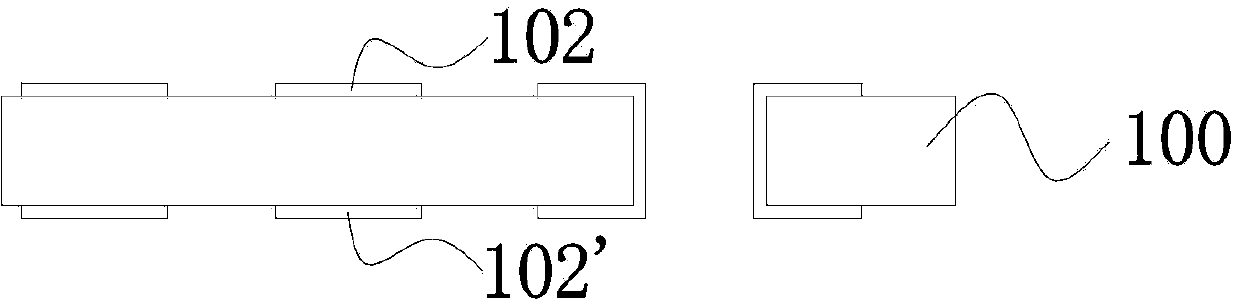

[0054] image 3 It is a schematic diagram of the structure of the metal seed layer provided by Example 2 of the present invention; as shown in the figure, the printing process is performed on both the front and back sides of the substrate 100 that has formed the alignment hole 101. The printing process includes: using screen printing Method, flexographic printing method, letterpress printing method or gravure printing method, the catalytic ink is printed on the front and back surfaces of the substrate 100 with the above-mentioned alignment holes 101 formed, and then hot air curing method or infrared curing method is used. 130°C ~ 150°C, such as 130°C, 135°C, 140°C, 145°C, 150°C, etc., for curing operation, and the time for curing operation is 40min ~ 60min, such as 40min, 42min, 48min, 52m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com