Flue gas waste heat recovery device for heat pipes

A flue gas waste heat recovery device technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of high exhaust gas temperature, high fuel consumption, low thermal efficiency of operation, etc., to reduce the exhaust gas temperature , Reduce fuel consumption and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below in conjunction with accompanying drawing:

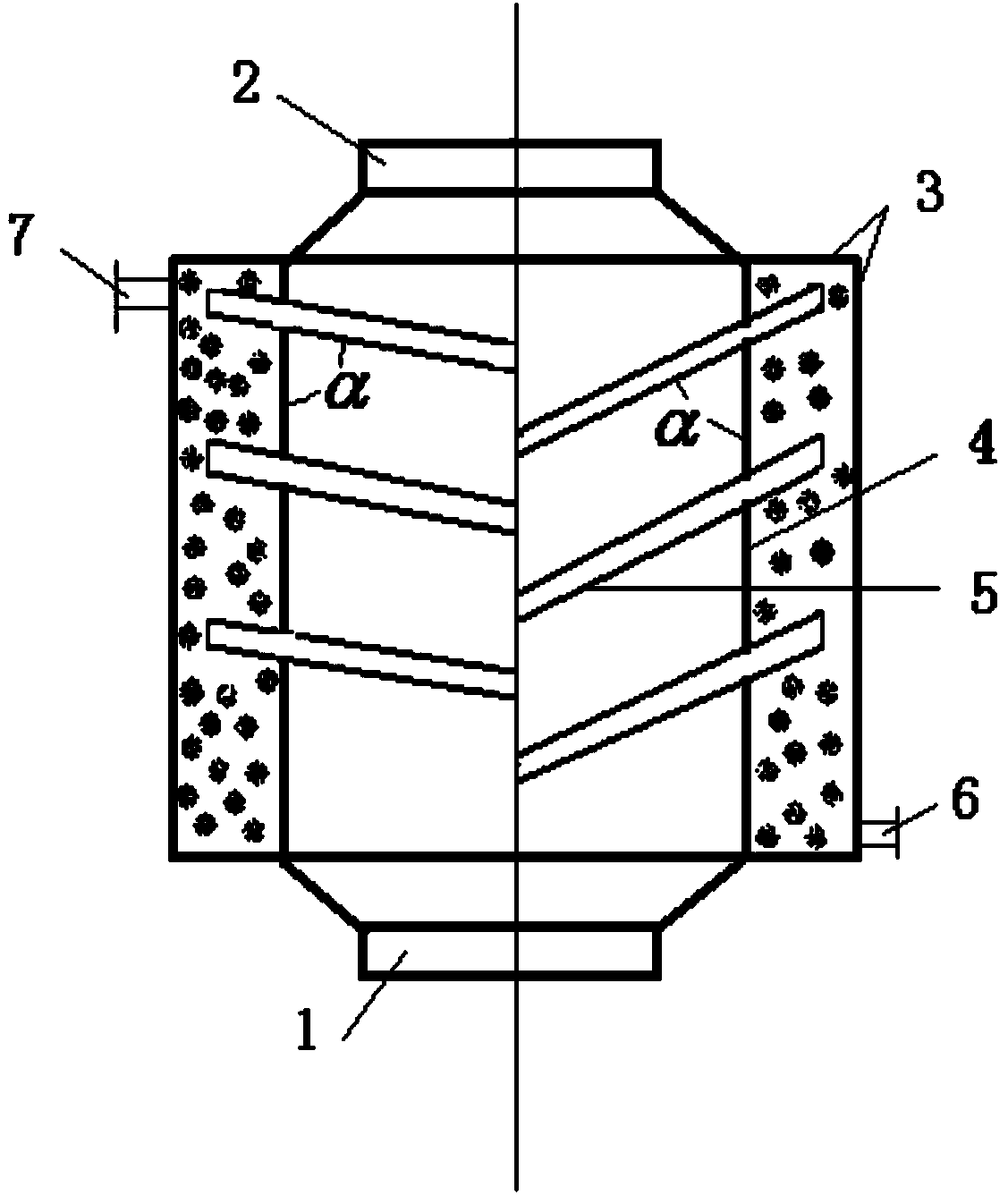

[0016] see figure 1 , The steel inner shell and outer shell are welded into a water jacket structure cylinder, and a set of heat pipes are welded on the inner wall of the water jacket. The flue gas inlet flange and the flue gas outlet flange are welded at both ends of the cylinder so as to be connected in series between the boiler and the root of the chimney to penetrate the flue gas passage. The water outlet pipe and the water inlet pipe are welded up and down on the water sleeve body so as to be connected in series to the return water pipe of the heating system. When the hot flue gas flows through the middle of the water jacket, it absorbs heat through the heat pipe to reduce the temperature of the flue gas and then discharges it. After the heat pipe absorbs heat, it transfers to the water jacket to raise the water temperature, and the water after the temperature r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com