Multi-rotation hydraulic valve

A rotary valve technology, applied in rotary piston engines, rotary or oscillating piston engines, valve details, etc., can solve the problems of small valve driving force, valve impact, low air source pressure, etc. Lock, reduce shock and vibration, improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

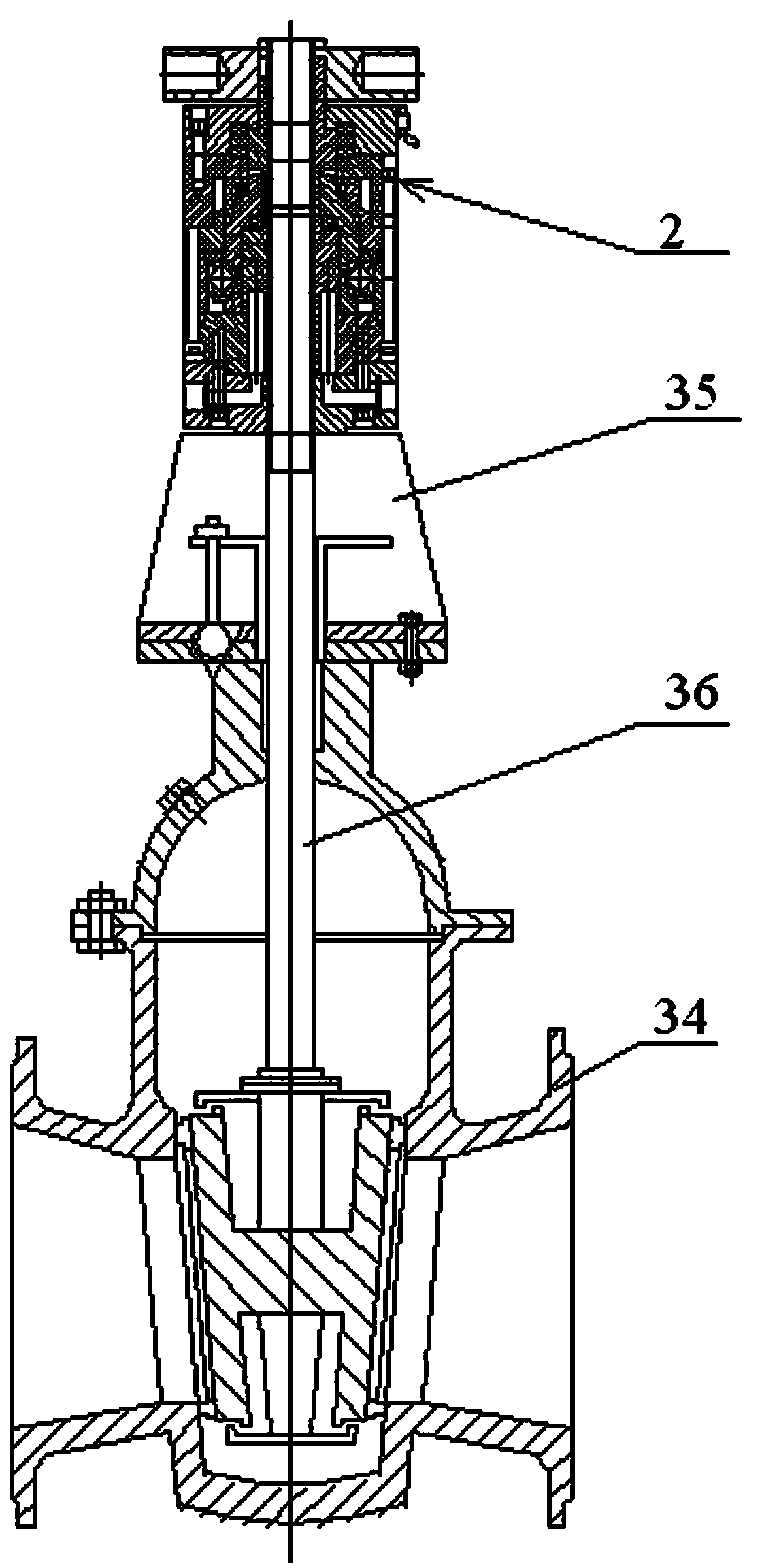

[0025] A multi-turn hydraulic valve includes a hydraulic motor 2, a valve 34 and a connecting bracket 35.

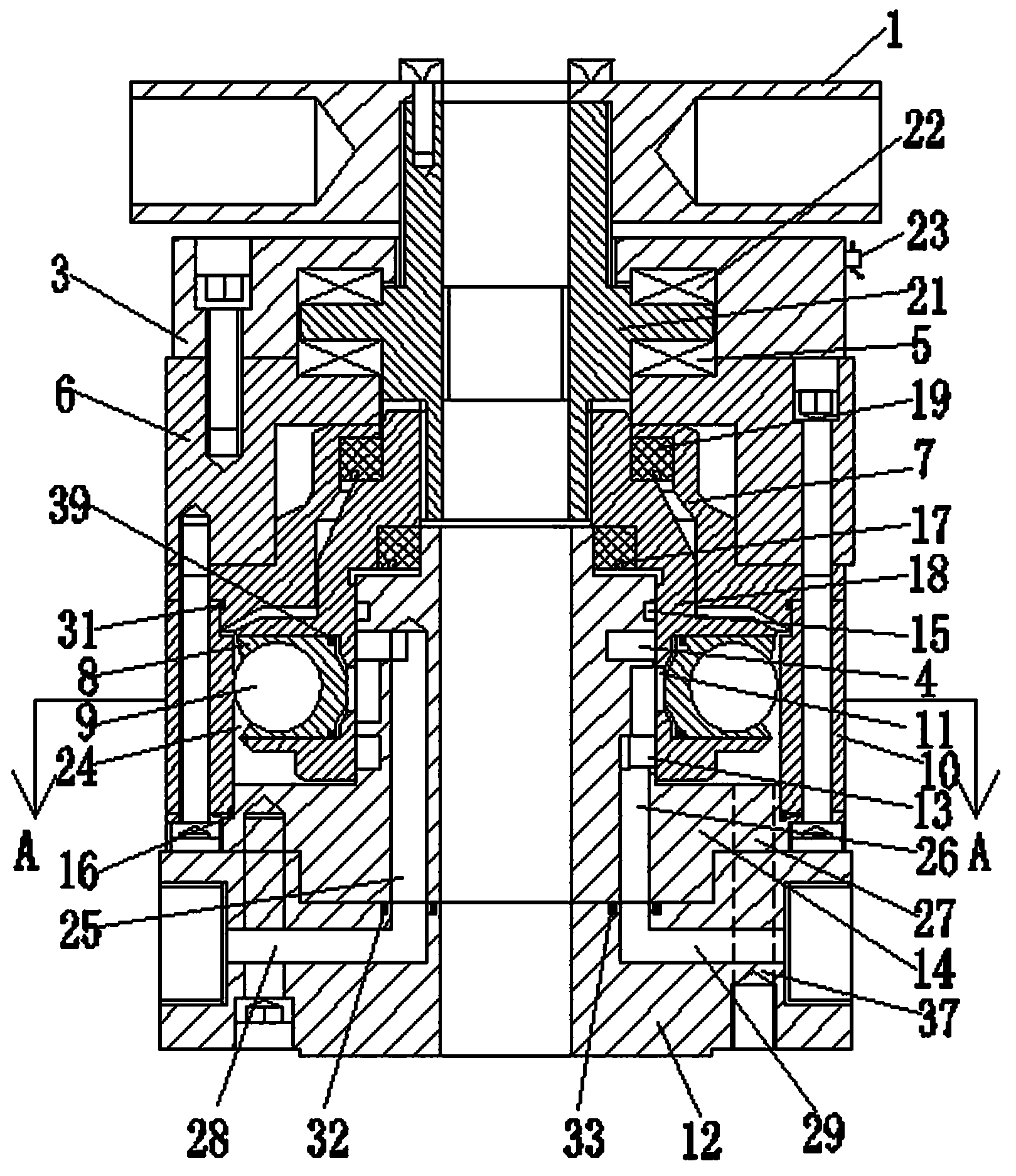

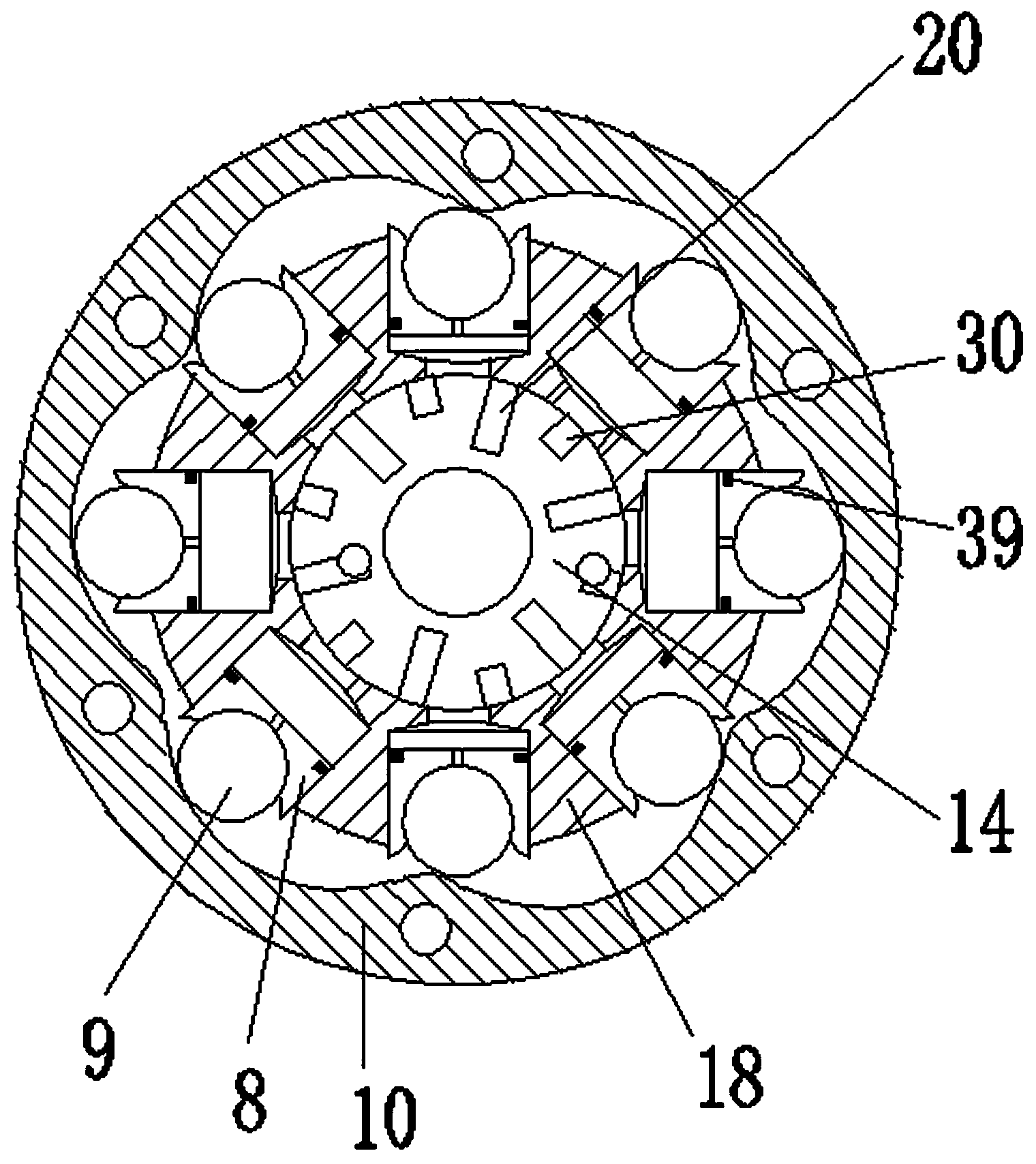

[0026] The hydraulic motor includes a manual hinge plate 1, a bearing end cover 3, a bearing seat 6, an output sleeve 21, a rotor 18, a sealing end cover 7, a stator 10, an oil distribution sleeve 14 and a lower end cover 12;

[0027] The bearing end cover 3 is fixedly connected with the bearing seat 6 through a plurality of screws, and both the bearing seat 6 and the bearing end cover 3 have a center hole; there is a step in the center hole of the bearing end cover 3, and the first thrust bearing 22 is installed, and the bearing seat 6 The second thrust bearing 5 is installed in the annular groove on the upper end surface; the output sleeve 21 is installed in the inner cavity surrounded by the bearing end cover 3 and the bearing seat 6, and is connected with the first thrust bearing 22 and the second thrust bearing The inner rings of 5 are separately fitted and fixed on...

Embodiment 2

[0036] The second embodiment is basically the same as the first embodiment, except that the valve 34 is a dark rod valve structure (see Figure 4 ), the elevating rod 38 does not move up and down. The lifting rod 36 in the first embodiment is composed of a solid upper valve stem connected with a lower valve stem. The upper end of the upper valve stem is connected with the key or tooth in the inner hole of the output sleeve 21 in the hollow plunger motor. The nuts fixed on the valve plate of the dark rod valve are connected by threads.

[0037] The rotation of the motor drives the upper and lower valve stems to rotate, and the nut drives the valve plate up and down along the rotation direction of the valve stem.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com