Fe-Co alloy/C composite nanofiber microwave absorbent, and preparation method and application thereof

A technology of composite nanofibers and microwave absorbers, applied in the fields of fiber chemical characteristics, chemical instruments and methods, rayon manufacturing, etc., can solve the problems of poor anti-oxidation and corrosion resistance, limit normal use, etc., and achieve improved microwave absorption performance , light weight and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of Fe-Co / C composite nanofiber microwave absorber of the present invention, concrete steps are as follows:

[0028] Step 1, 0.7g polyacrylonitrile (PAN, average molecular weight 150,000) was added to a conical flask filled with 8.6g dimethylformamide (DMF), heated in a water bath at 50°C and magnetically stirred for 3h until PAN was completely dissolved, Then add 0.4653g iron acetylacetonate and 0.2347g cobalt acetylacetonate, and continue magnetic stirring at normal temperature for 15h to obtain a uniform, transparent and stable spinning solution. The mass fraction of PAN in this spinning solution is 7%, and the amount of metal salt The mass fraction is 7%, the ratio of the amount of the two substances is 2:1, and the rest is solvent DMF;

[0029] Step 2, move the prepared spinning solution into the electrospinning device, under the conditions of voltage of 12kV, receiving distance of 23cm, solution supply rate of 0.3mL / h, spinneret diameter of 0...

Embodiment 2

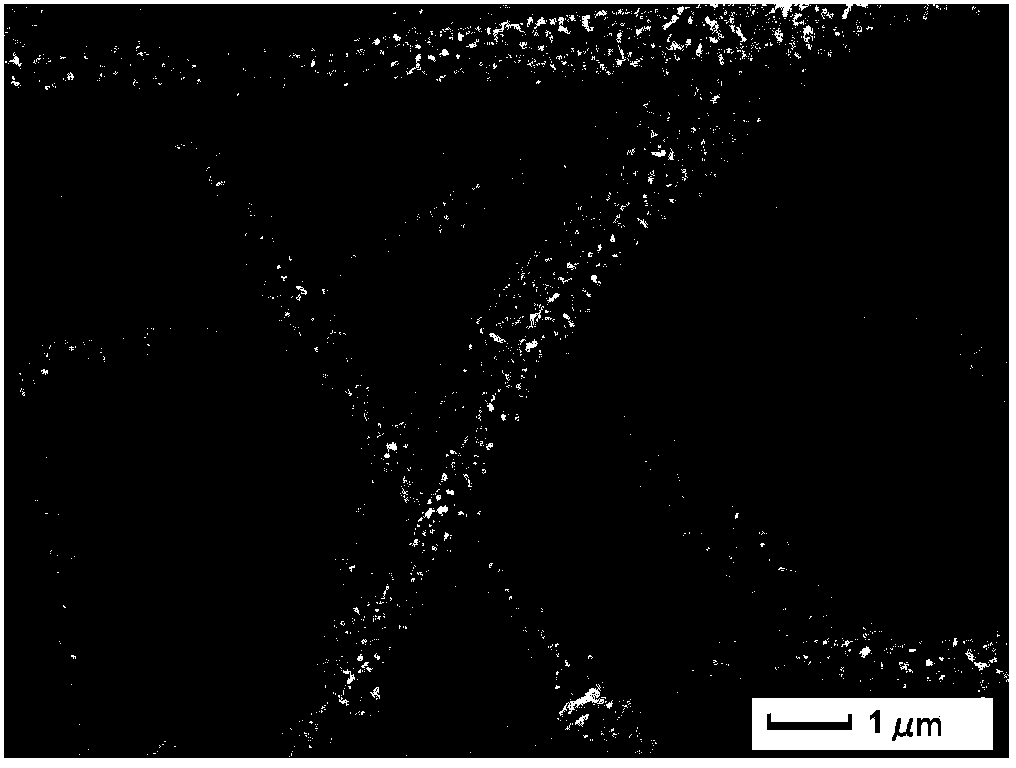

[0033]The basic process of the preparation method of the Fe-Co / C composite nanofiber microwave absorber of embodiment 2 is the same as embodiment 1, and different from embodiment 1 is: in embodiment 2 spinning solutions, the quality of iron acetylacetonate and cobalt acetylacetonate is respectively 0.5318 and 0.2682g, the metal salt content is 8wt%, and the carbonization temperature is 1000°C, the average diameter of the obtained Fe-Co alloy / C composite nanofiber microwave absorber is about 190nm.

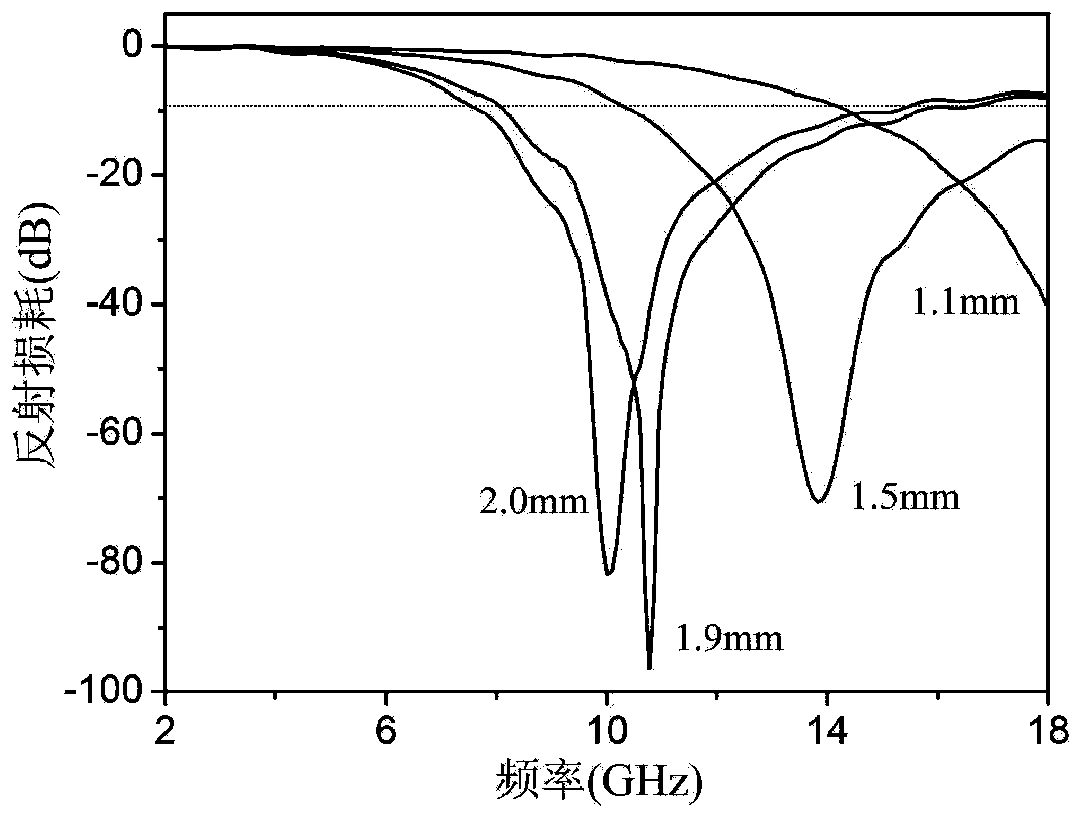

[0034] Using silica gel as the matrix, the Fe-Co alloy / C composite nanofiber microwave absorber prepared in Example 2 was evenly mixed with silica gel to form a single-layer wave-absorbing coating. mm, the minimum reflection loss reaches –96dB, the effective absorption bandwidth is 7.5GHz, and the frequency range is 8.1~15.6GHz.

Embodiment 3

[0036] The basic process of the preparation method of the Fe-Co / C composite nanofiber microwave absorber of embodiment 3 is the same as that of embodiment 1, and the difference from embodiment 1 is that the masses of iron acetylacetonate and cobalt acetylacetonate in embodiment 3 are respectively 0.2659 and 0.1341g , the metal salt content is 4wt%, the pre-oxidation temperature is 260 ℃, and the carbonization temperature is 1200 ℃. The average diameter of the obtained Fe-Co alloy / C composite nanofiber microwave absorber is about 260nm.

[0037] Using silica gel as the matrix, the Fe-Co alloy / C composite nanofiber microwave absorber prepared in Example 3 was evenly mixed with silica gel to form a single-layer wave-absorbing coating. mm, the minimum reflection loss is –67dB, the effective absorption bandwidth is 6.6GHz, and the frequency range is 9.1~15.7GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com