Water-based paper and plastic laminating/peelable adhesive and method for manufacturing same

A technology of peeling off glue and paper plastic, applied in the directions of adhesive additives, non-polymer adhesive additives, wax adhesives, etc. Ease of use, complete paper protection, and gloss-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

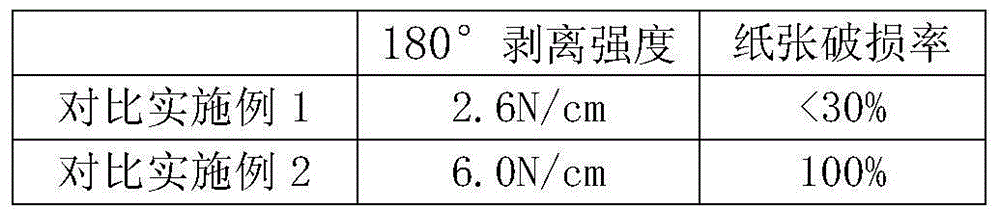

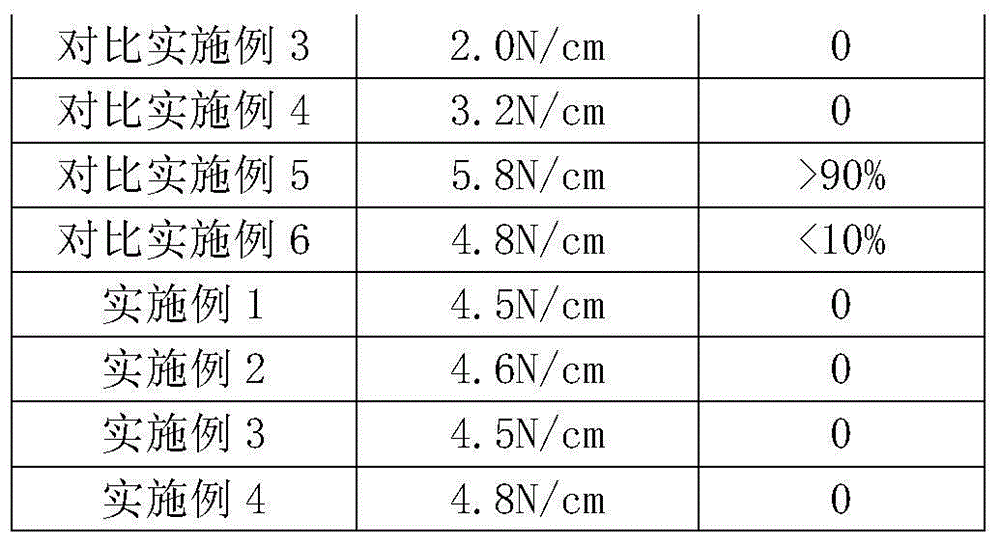

Examples

Embodiment 1

[0054] (1) Take 15g Silok-414L from Silok Chemical, 20g BASF water-based wax emulsion WE-6, 5g Longkou Yijiu Chemical's TL-204 and 15g Litai Chemical's water-based PU330, 20g Qingfeng Chemical's UH650, 10g Haohe After mixing the 4825 of the chemical industry, put it in the dispersing kettle, add 0.3g of the SPA-202 defoamer of the horizontal stacking chemical at the stirring speed of 700 rpm and room temperature, and disperse for 10 minutes;

[0055] (2) After adjusting the stirring speed in step (1) to 300rpm, add 3g of clay and 3g of kaolin, and stir for 15min;

[0056] (3) Keep the stirring speed in (2) unchanged, add 4g terpene resin emulsion T-120, 5g natural latex MRD2116, and disperse for 15min;

[0057] (4) Keep the stirring speed in (3) unchanged, add 2g methyltriethoxysilane, 3g 3-aminopropyltriethoxysilane, and disperse for 10min;

[0058] (5) Keep the stirring speed in (4) unchanged, add 0.2g Hantai Chemical's HT-925, adjust the viscosity of the system to the construction ...

Embodiment 2

[0070] (1) Take 10g Meilun Chemical's high melting point oxidized polyethylene wax emulsion ML-1600, 15g Shanghai Modian Chemical's modified polyethylene wax emulsion AE810, 10g Shanghai Modian Chemical's water-based polyethylene primary dispersion PE02 and 20g Bayer U54, 15g Audemei F207, 15g Litai Chemical's water-based PU330 are mixed and placed in a dispersion kettle. At a stirring speed of 1000rpm, add 0.5g BYK-045 defoamer from BYK at room temperature and disperse for 20min;

[0071] (2) After adjusting the stirring speed in step (1) to 500 rpm, add 1 g of clay and 2 g of calcium carbonate, and stir for 20 minutes;

[0072] (3) Keep the stirring speed in (2) unchanged, add 6g water-based rosin glyceride emulsion T-201, 4g water-based epoxy resin emulsion BC5175, and disperse for 30 minutes;

[0073] (4) Keep the stirring speed in (3) unchanged, add 2g of 3-aminopropyltriethoxysilane, 2g of 3-glycidoxypropyltrimethoxysilane, and disperse for 20min;

[0074] (5) Keep the stirring ...

Embodiment 3

[0086] (1) Take 15g BASF water-based wax emulsion WE-1, 10g Shanghai Xinnuo Chemical's WE-118B, 10g Longkou Yijiu Chemical's TL-204, 15g Haohe Chemical 4825, 20g Litai Chemical's water-based PU330, 20g Qingfeng Chemical After mixing the UH650, place it in a dispersion kettle, add 0.2g of BYK’s BKY-045, 0.2g of Deqian’s DEUCHEM091 defoamer at room temperature at a stirring speed of 900rpm, and disperse for 25min;

[0087] (2) After adjusting the stirring speed in step (1) to 500 rpm, add 5 g of chalk powder and 5 g of calcium carbonate, and stir for 60 minutes;

[0088] (3) Keep the stirring speed in (2) unchanged, add 2g terpene resin emulsion T-120, 3g water-based rosin resin emulsion 10, and disperse for 25min;

[0089] (4) Keep the stirring speed in (3) unchanged, add 2g methyltriethoxysilane, 3g 3-aminopropyltriethoxysilane, and disperse for 30min;

[0090] (5) Keep the stirring speed in (4) unchanged, add 0.2g AD-13 from Ondi Chemicals, 0.2g HT-925 from Hantai Chemicals, adjust t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com