Method for recycling disposal of silicon tetrachloride slag slurry produced in polycrystalline silicon production and device thereof

一种处置方法、四氯化硅的技术,应用在氧化硅、二氧化硅、卤化硅化合物等方向,能够解决石灰乳或碱液消耗大、水用量大、四氯化硅利用低等问题,达到高换热系数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

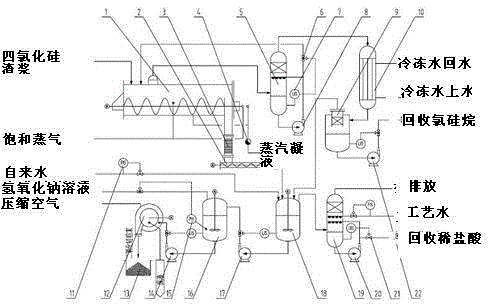

[0051] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings:

[0052] A method for recovering and disposing of silicon tetrachloride slag is characterized in that:

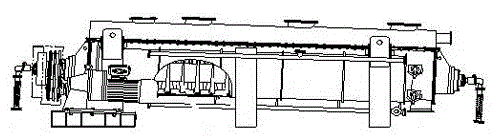

[0053] The liquid mainly composed of chlorosilane (which still contains trichlorosilane, silicon powder, aluminum ions and other substances) from the upstream section first continuously enters the paddle dryer 1 (produced by Lanzhou Ruide Drying Technology Co., Ltd., patent number: 200820170768.X), through the indirect heating and evaporation of paddle dryer 1, the steam trap 4 is used to separate the steam-water mixture after heat exchange and condensation from the heat shaft of paddle dryer 1 and the jacket, so as to ensure the saturated water condensed in the dryer The steam is discharged in time; the volatile content of the slurry exiting the dryer is controlled at 20% to 50%, and it flows through the bellows 3 and enters the screw pump 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com