Negative pressure and positive pressure automatic ignition method of hydrogen chloride synthesis furnace

An automatic ignition and synthesis furnace technology, applied in the direction of chlorine/hydrogen chloride, etc., can solve the problems of manpower consumption and low safety factor, and achieve the effect of improving the degree of automation, improving the safety factor and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

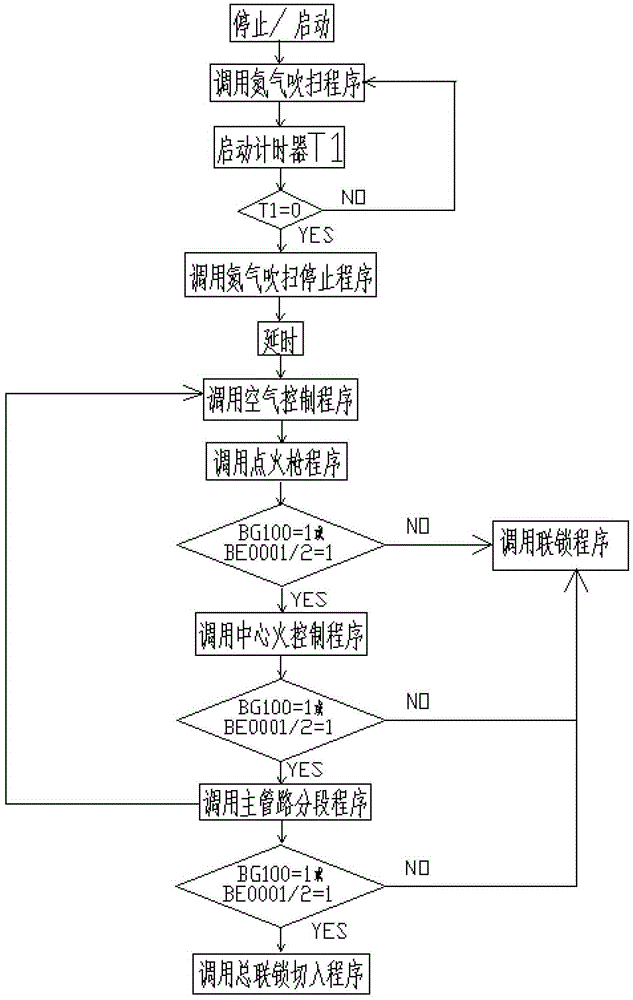

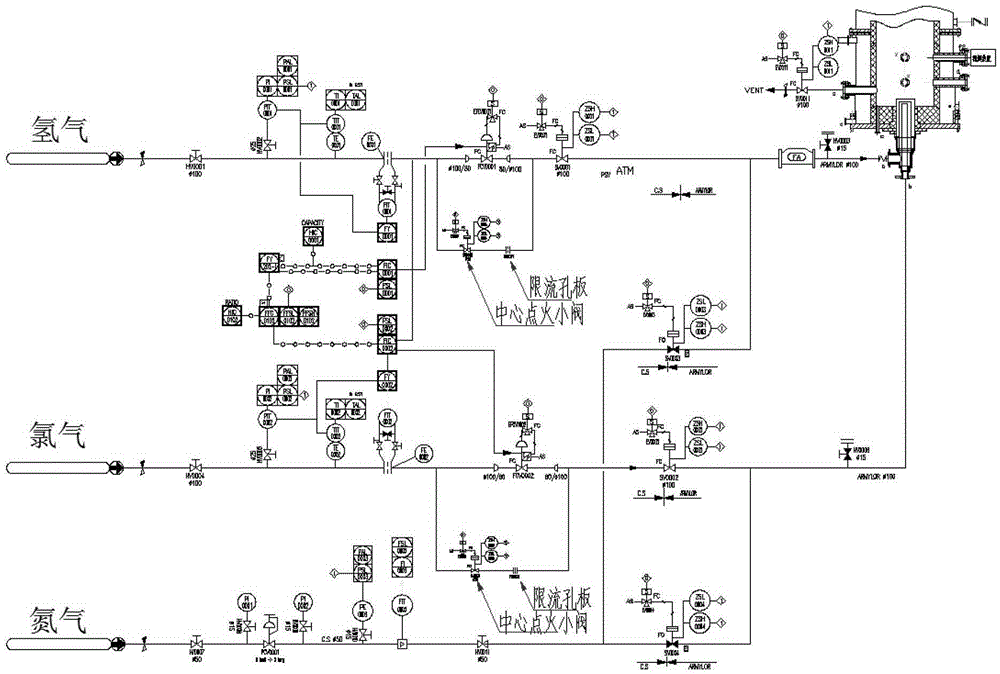

[0026] see Figure 1-Figure 5 , Negative pressure ignition is a common operation method in the long-term artificial ignition process. The present invention needs to completely program this process. After pressing the start button, the safety valve in charge of hydrogen and chlorine will automatically open, and the nitrogen valve will automatically open. The furnace will automatically flush nitrogen. After the synthesis furnace is flushed with nitrogen, the furnace door of the synthesis furnace will be opened automatically, and at the same time, the fan or hydraulic pump will be turned on at the emptying place for suction. Since the furnace door of the synthesis furnace is open, the air will enter from the furnace door. , establish an air field in the synthesis furnace, that is, the oxidant when hydrogen is burned, the oxidant is sufficient and excessive, keep the air circulation for a certain period of time, and ensure that the air field in the synthesis furnace is sufficient. ...

Embodiment ( 2

[0032] see figure 1 , 6 7. The synthesis furnace is completely ignited and raised in a closed working condition. The whole process is constantly judged and stepped. On the premise of ensuring safety and stability, the one-key ignition mode of the synthesis furnace is realized. Any judgment and actual If it does not match, implement the security protection program.

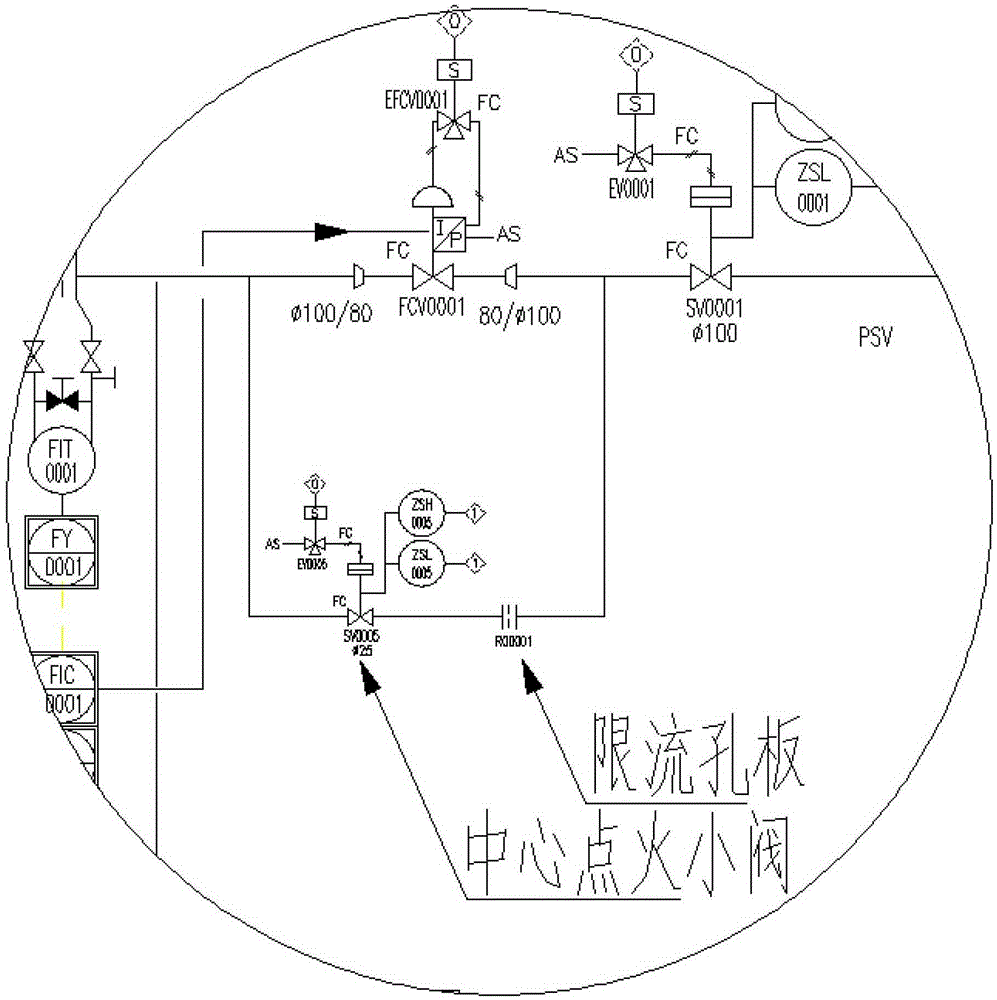

[0033] Once the auto-ignition system has established the pilot flame, the primary hydrogen can be mixed with the primary combustion air to establish the primary combustion flame. When starting up, the combustion-supporting air flow rate entering the system is consistent with the required chlorine gas intake flow rate at the minimum production capacity of the synthesis unit. Therefore, after the nitrogen purge is completed, the combustion-supporting air flow controller FFIC-0405 / HIC-0004 inputs 200Nm3 / h of combustion air.

[0034] The amount of hydrogen should be consistent with the required hydrogen intake flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com