PCB (Printed Circuit Board) passing mechanism with board pick-up and placement function

A technology of passing plate mechanism and closing plate, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of lack of flexibility, single function, large volume, etc., and achieve the effect of saving labor input costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

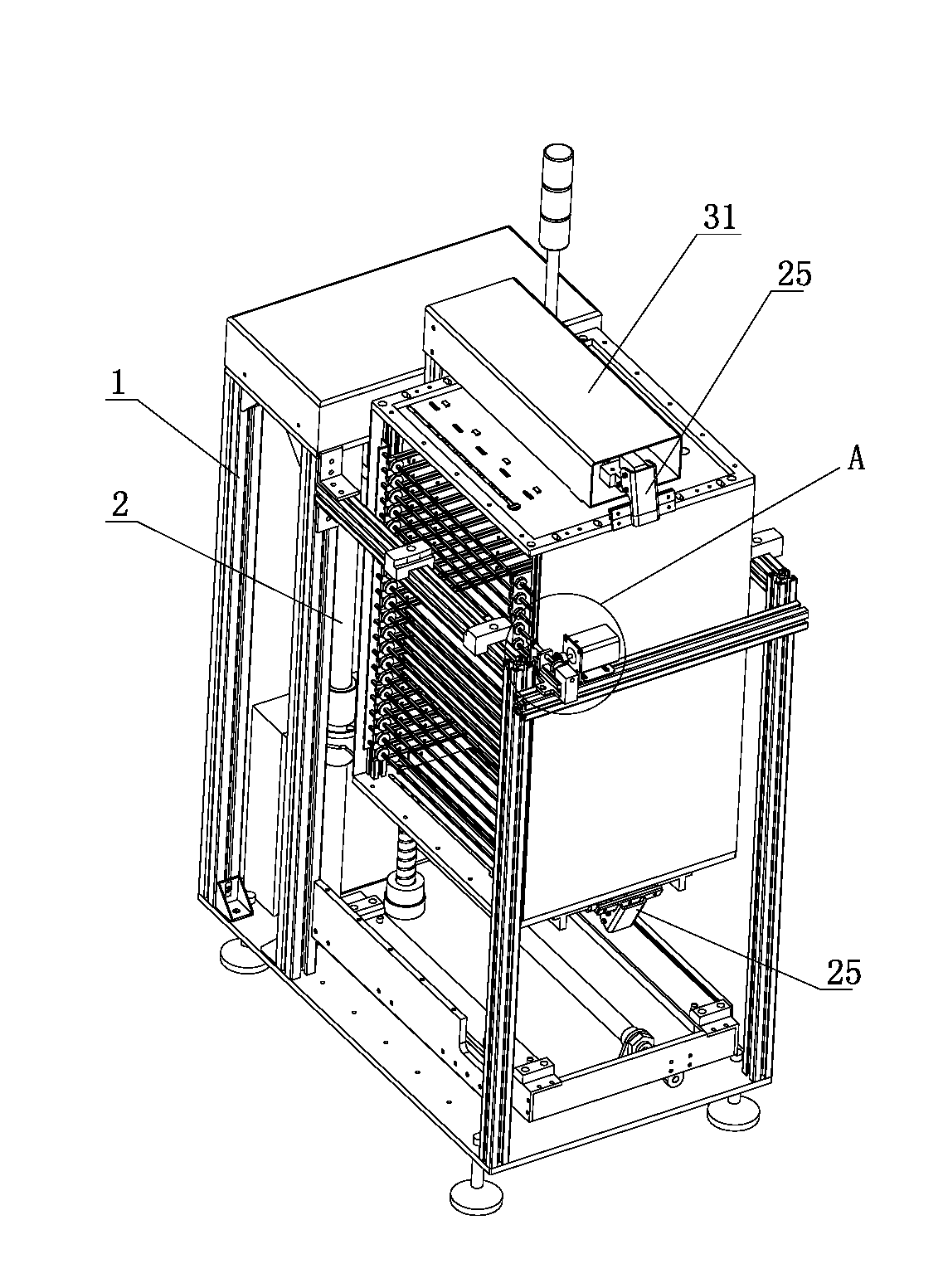

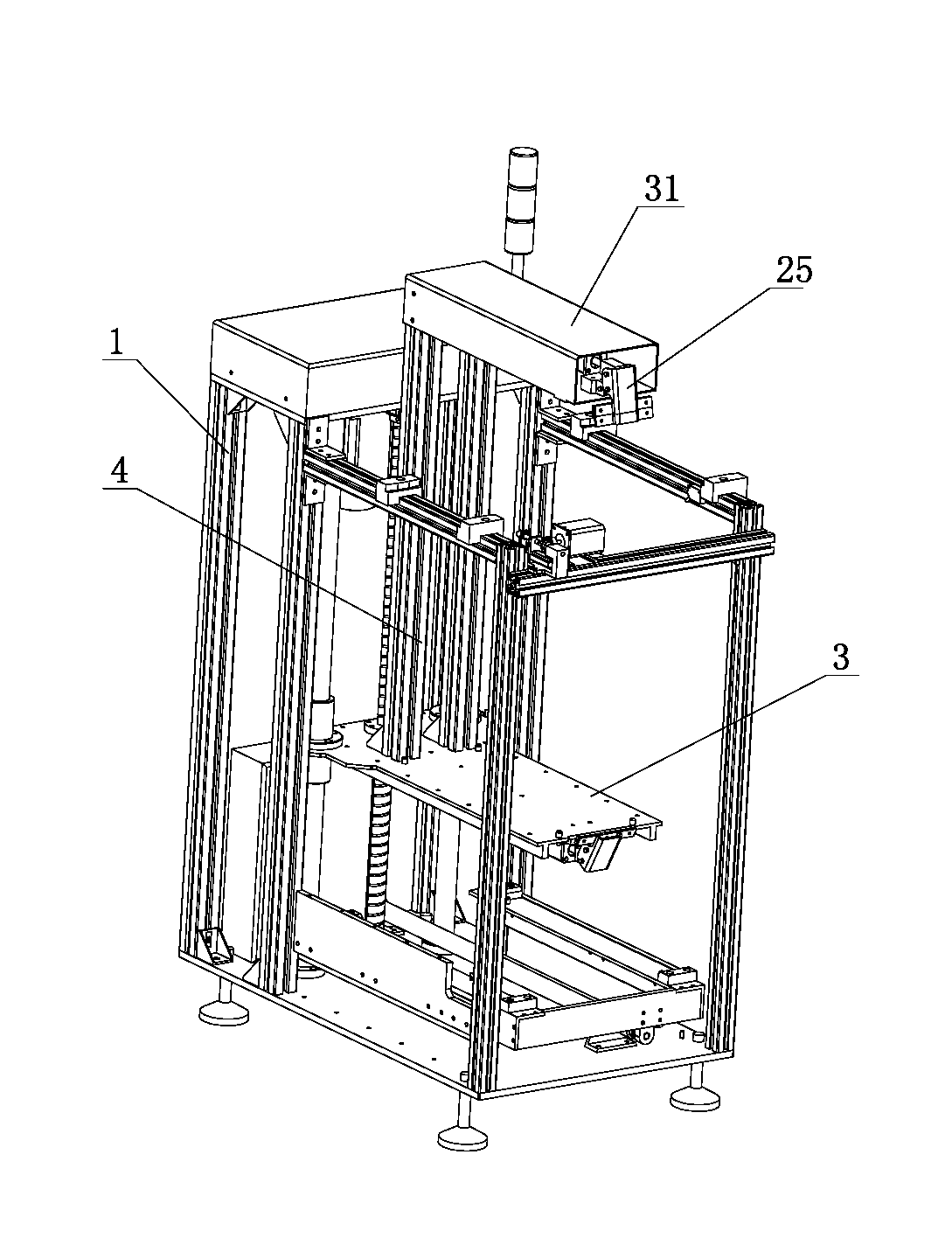

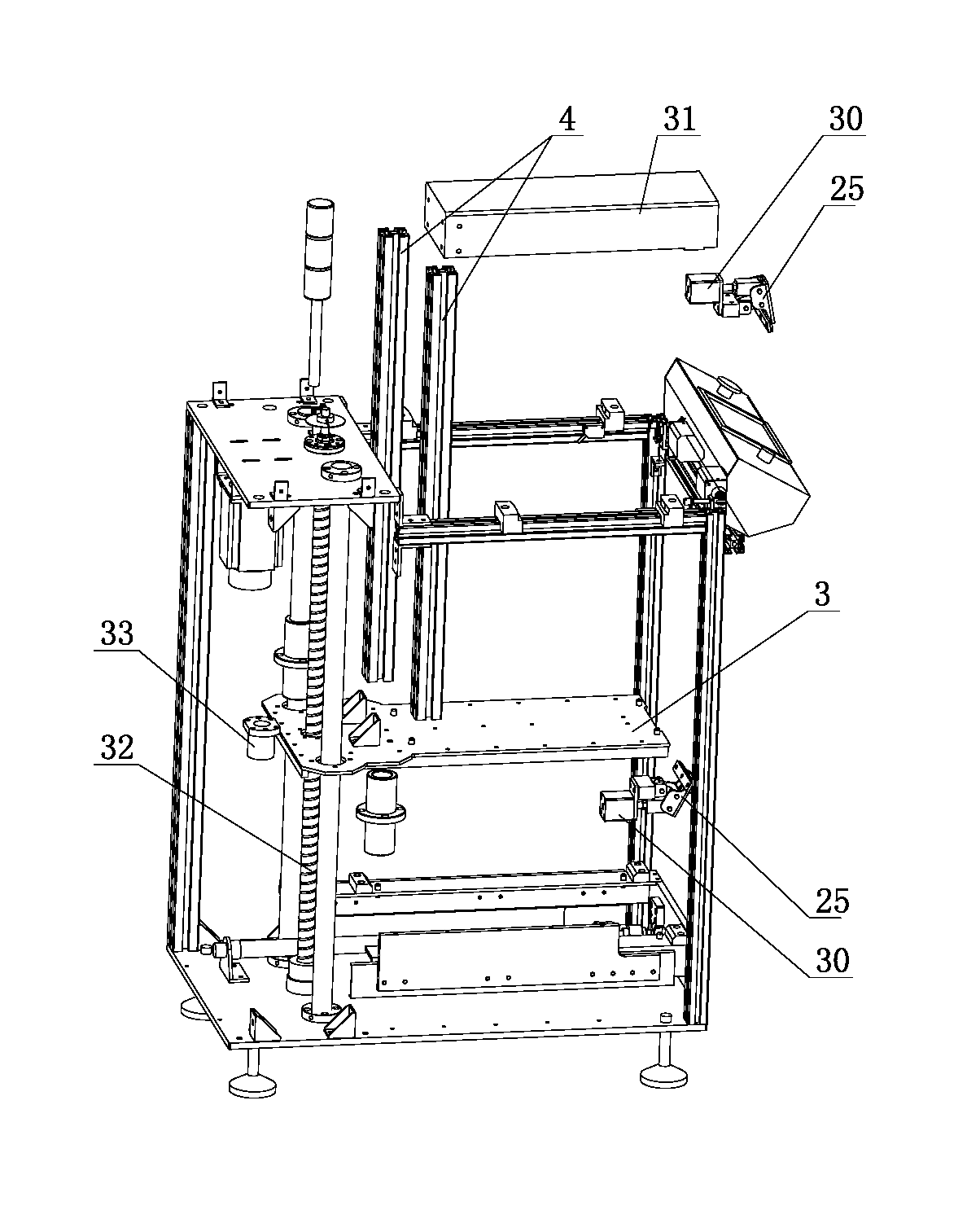

[0031] Such as Figure 1 to Figure 9 As shown, a PCB board passing mechanism with the function of receiving and releasing boards includes a frame 1, a turnover box, a retractable transmission device installed on the frame 1, and a guide rail 2 erected on the frame 1. The guide rail 2 is equipped with a bearing plate 3 that moves up and down along the guide rail 2, and the frame 1 is equipped with a lifting drive mechanism for driving the bearing plate 3 to move up and down; the inner end of the bearing plate 3 is equipped with a support frame 4, The outer end of the carrying plate 3 is equipped with a clamping frame device, and the bottom of the frame 1 is equipped with a frame pushing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com