Feed forward and feedback adjustment of motor torque during clutch engagement

A clutch and disengagement clutch technology, applied in the field of clutch locking, can solve the problem of difficulty in estimating the torque of the engine and the clutch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A detailed description of illustrative embodiments of the invention is provided below. The disclosed embodiments are exemplary of the invention, which may be embodied in various and alternative forms. The drawings are not necessarily drawn to scale. Some features can be zoomed in or out to reveal details of a particular part. Specific structural and functional details disclosed in this application are not to be interpreted as limiting, but merely as a representative basis for teaching one skilled in the art how to practice the invention.

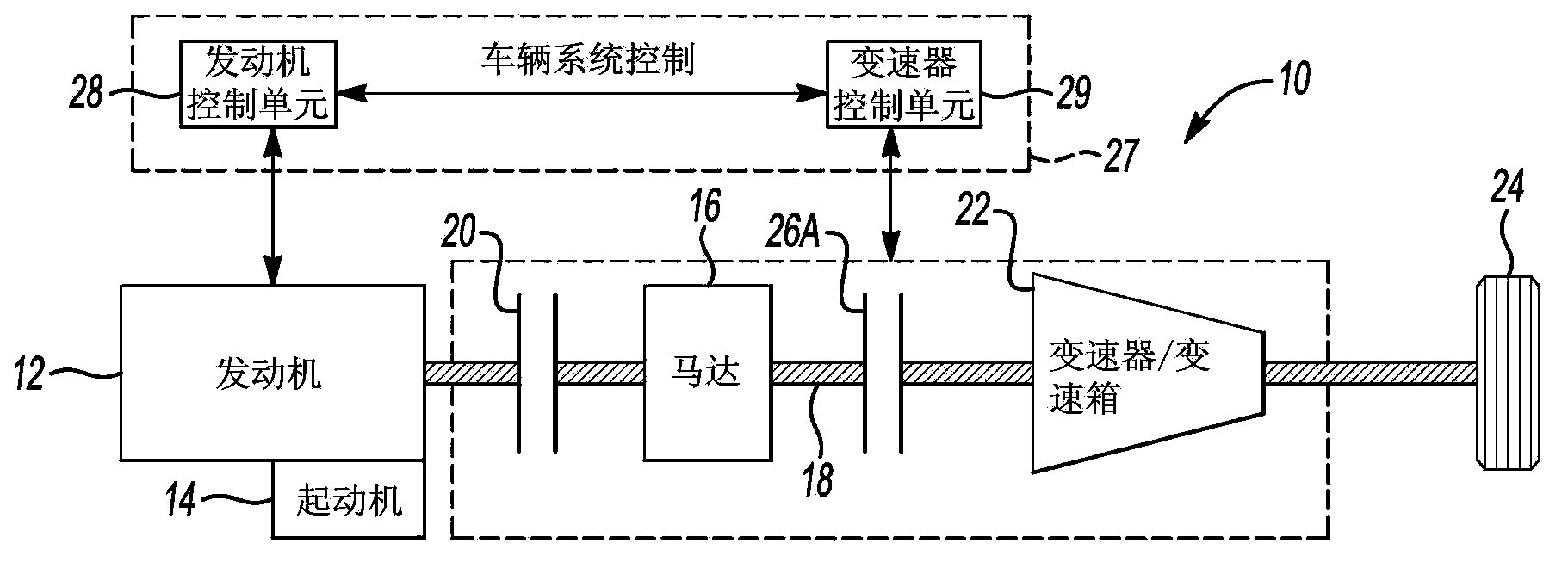

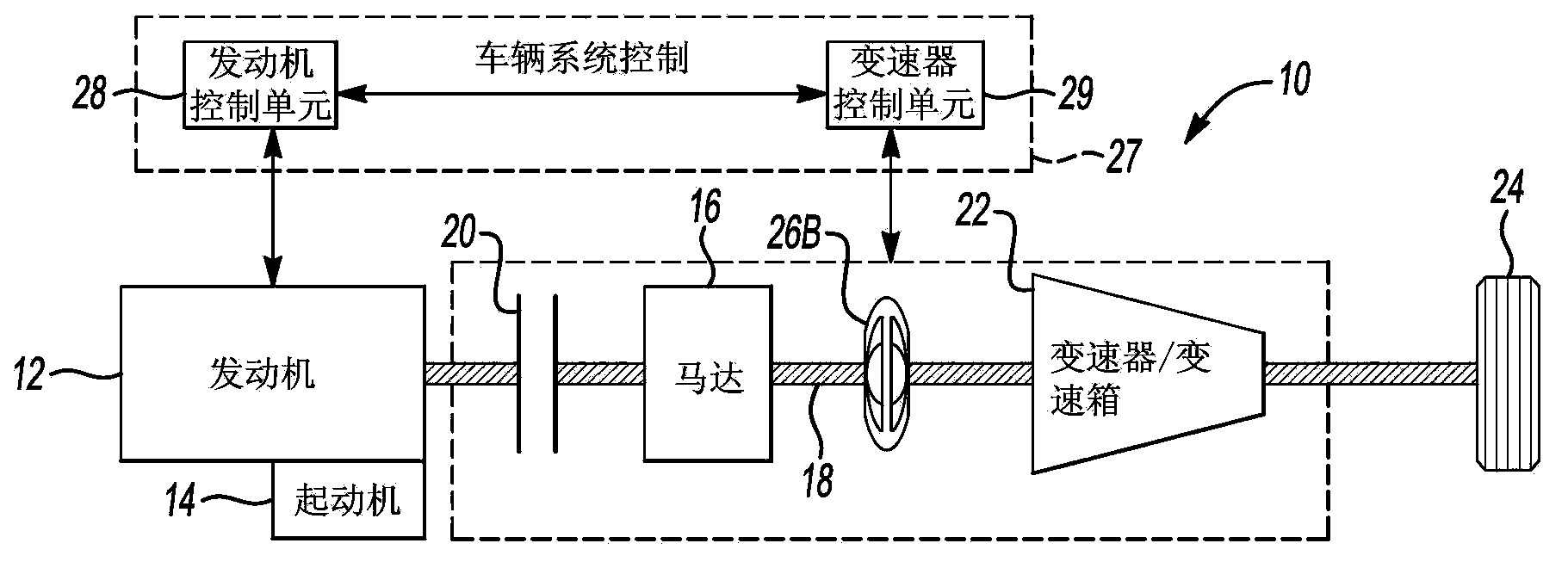

[0026] refer to Figure 1A and Figure 1B , shows the modular hybrid transmission 10 in schematic form. The engine 12 is operatively connected to a starter 14 for starting the engine 12 when additional torque is required. A motor (or electric machine) 16 is operably connected to a driveline 18 . A disconnect clutch 20 is provided on the driveline 18 between the engine 12 and the electric machine 16 . Also provided on the driveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com