An auxiliary device for carbon arc gouging of flat welds

A carbon arc gouging and auxiliary device technology, applied in electrode support device, electrode characteristics, welding equipment and other directions, can solve the problems of fluctuating upper and lower weld centerline planing deviation, increasing welding cost of bead layers, increasing welding defects, etc. , to achieve uniform width and depth, improve labor productivity, simple and lightweight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

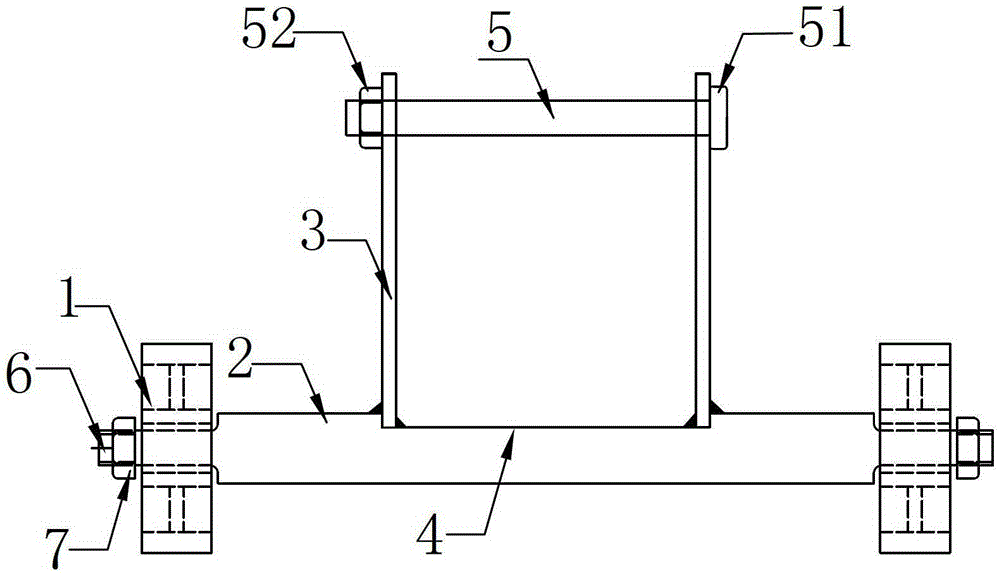

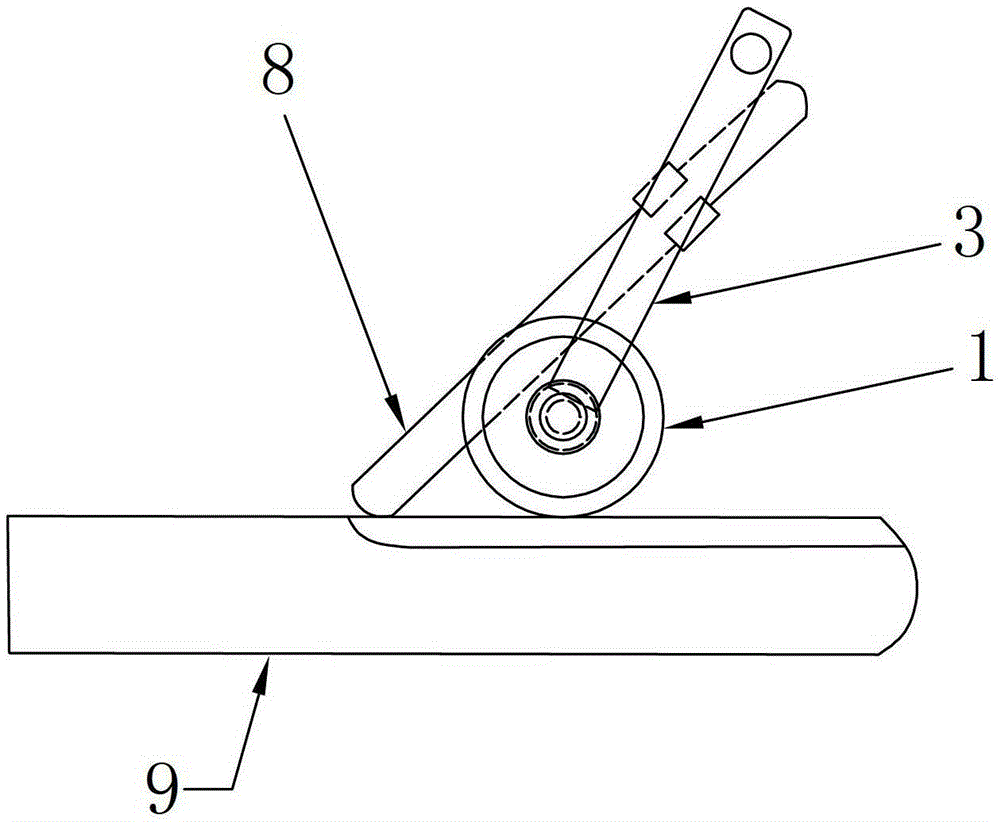

[0018] refer to figure 1 and figure 2 , an auxiliary device for carbon arc gouging of straight weld seams according to the present invention, comprising a bracket for supporting the carbon arc gouging torch and traveling wheels 1 installed on both sides of the bracket, the bracket includes supporting horizontal steel 2 1. Two vertical flat steels 3 connected with the supporting horizontal steel 2, the traveling wheels 1 are installed on the two ends of the supporting horizontal steel 2, the upper ends of the two vertical flat steels 3 are provided with installation holes, and the round steel 5 with external threads It is connected with two vertical flat steels 3 through the mounting holes, one end of the round steel 5 has a pin cap 51 , and the other end is fixed by a fastening nut 52 . During use, the carbon arc gouging torch is placed on the supporting horizontal steel 2, and the carbon arc gouging torch is fixedly connected with the device through the round steel 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com