Filter screen mechanism and fruit and vegetable squeezing and grinding machine using same

A fruit and vegetable pressing mill and filter screen technology, which is applied in the direction of household machinery, applications, household appliances, etc. for filtering food, can solve the problems that fibers are easy to block the mesh holes, reduce the nutritional content of fruit puree, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

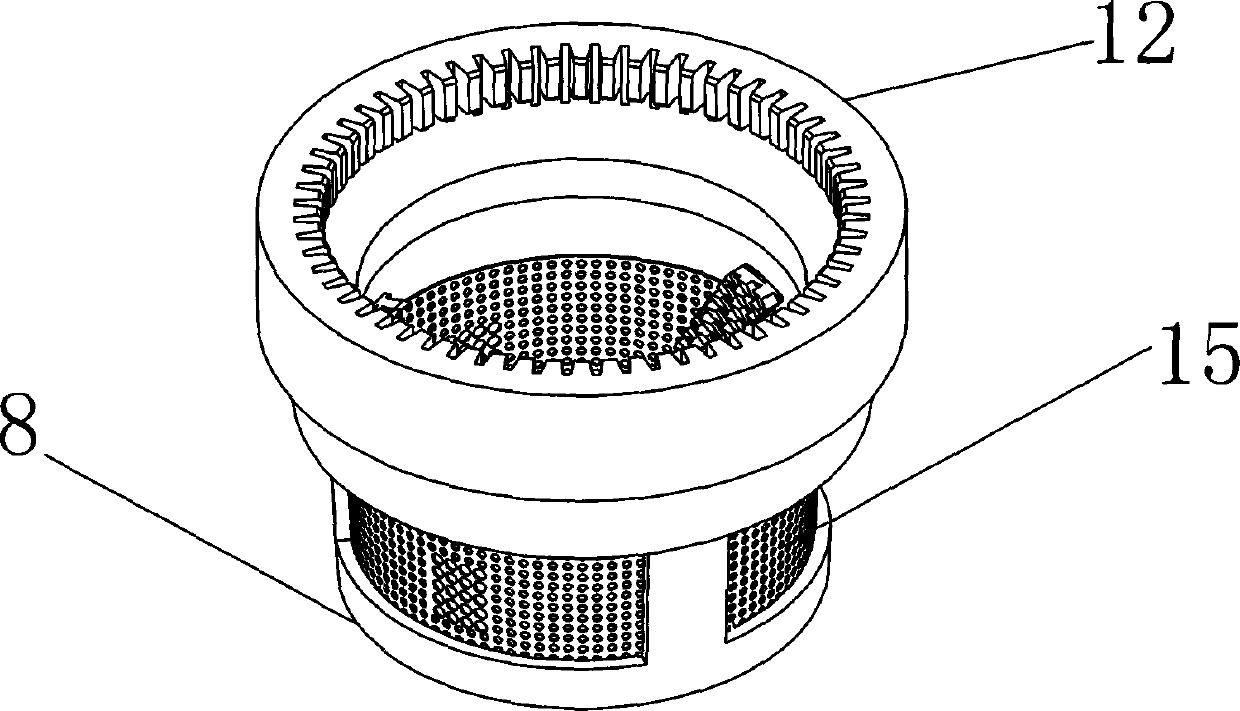

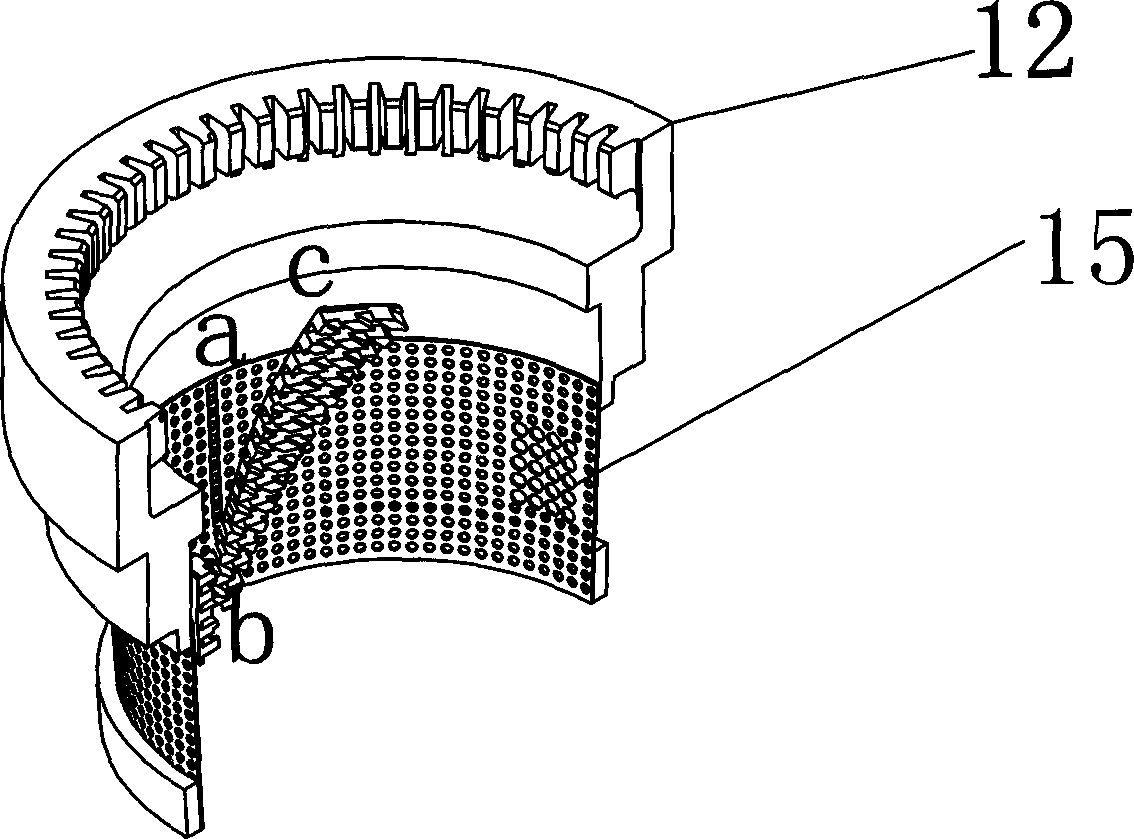

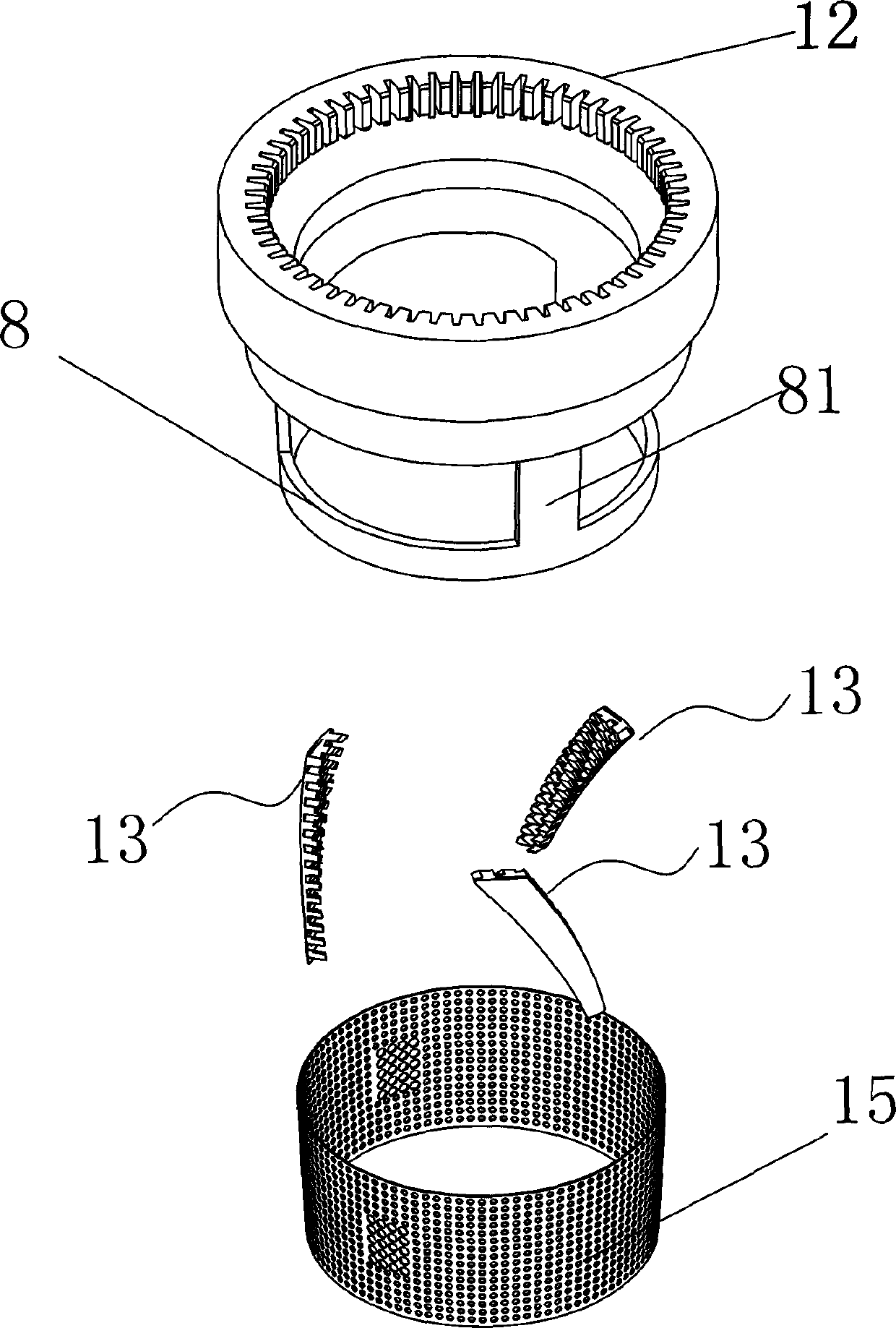

[0030] Such as Figure 6 As shown, the filter screen mechanism for the fruit and vegetable mill of the present invention includes an upper filter screen 15 and a lower filter screen 17 , and a middle ring screen 23 is also arranged between the upper filter screen 15 and the lower filter screen 17 . Such as Figure 5 As shown, a shading ring 33 is fixed on the middle circle net 23, and several breaches 331 are arranged on the shielding circle 33, and the said breach 331 places are the mesh area of the middle circle net, and the mesh apertures of the middle circle net are respectively larger than the upper filter net. holes and lower strainer mesh. A middle ring frame 2 is also connected to the shielding ring 33 , and a plurality of windows 231 corresponding to the notches 331 on the shielding ring 33 are provided on the middle ring frame 2 . Such as Figure 4 As shown, the middle frame 2 is rotatably sleeved on the shielding ring 33 . In addition, a locking bolt 39 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com