Temperature averaging device of steam chamber heat pipe/microchannel cold plate composite structure

A composite structure and micro-channel technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of obvious size limitation, failure to achieve overall temperature uniformity, and difficulty in achieving uniform temperature effect, etc., to achieve thin height, high utilization rate, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

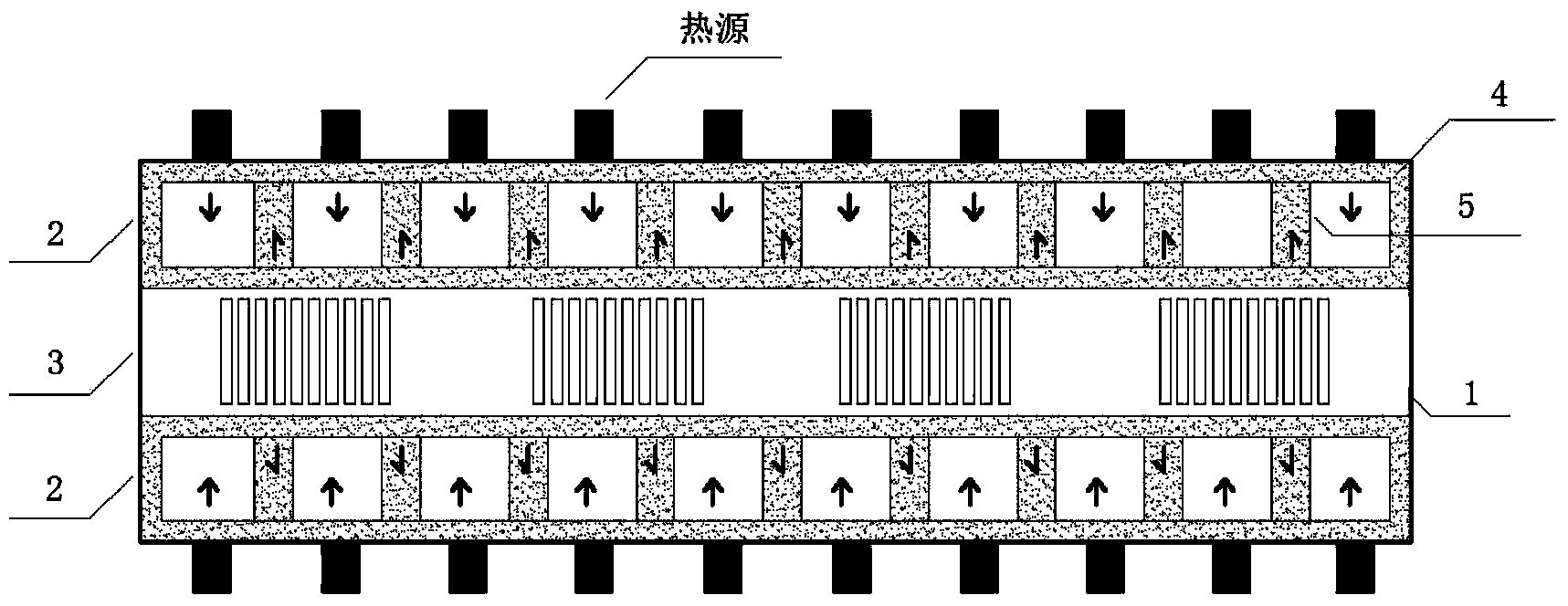

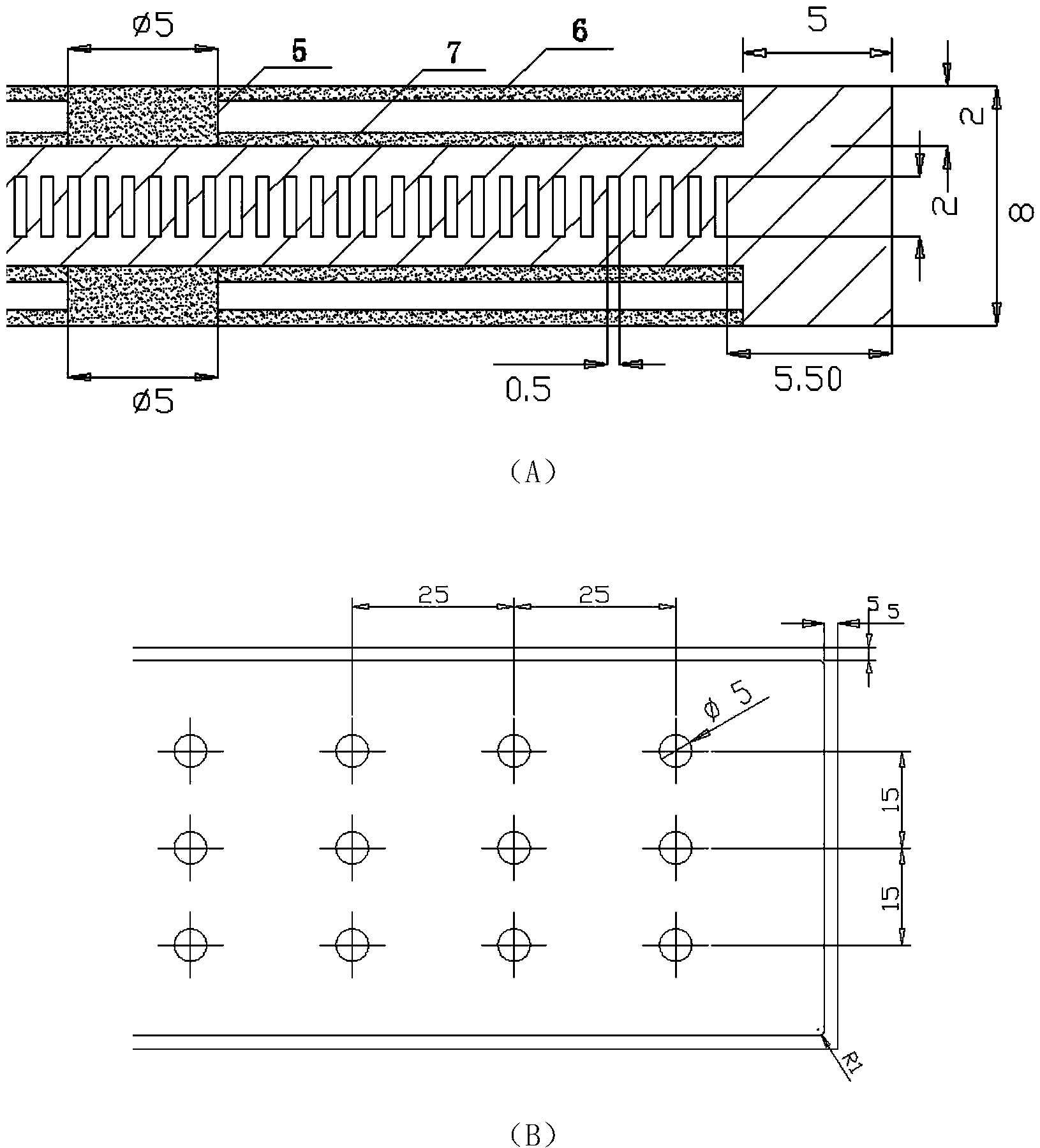

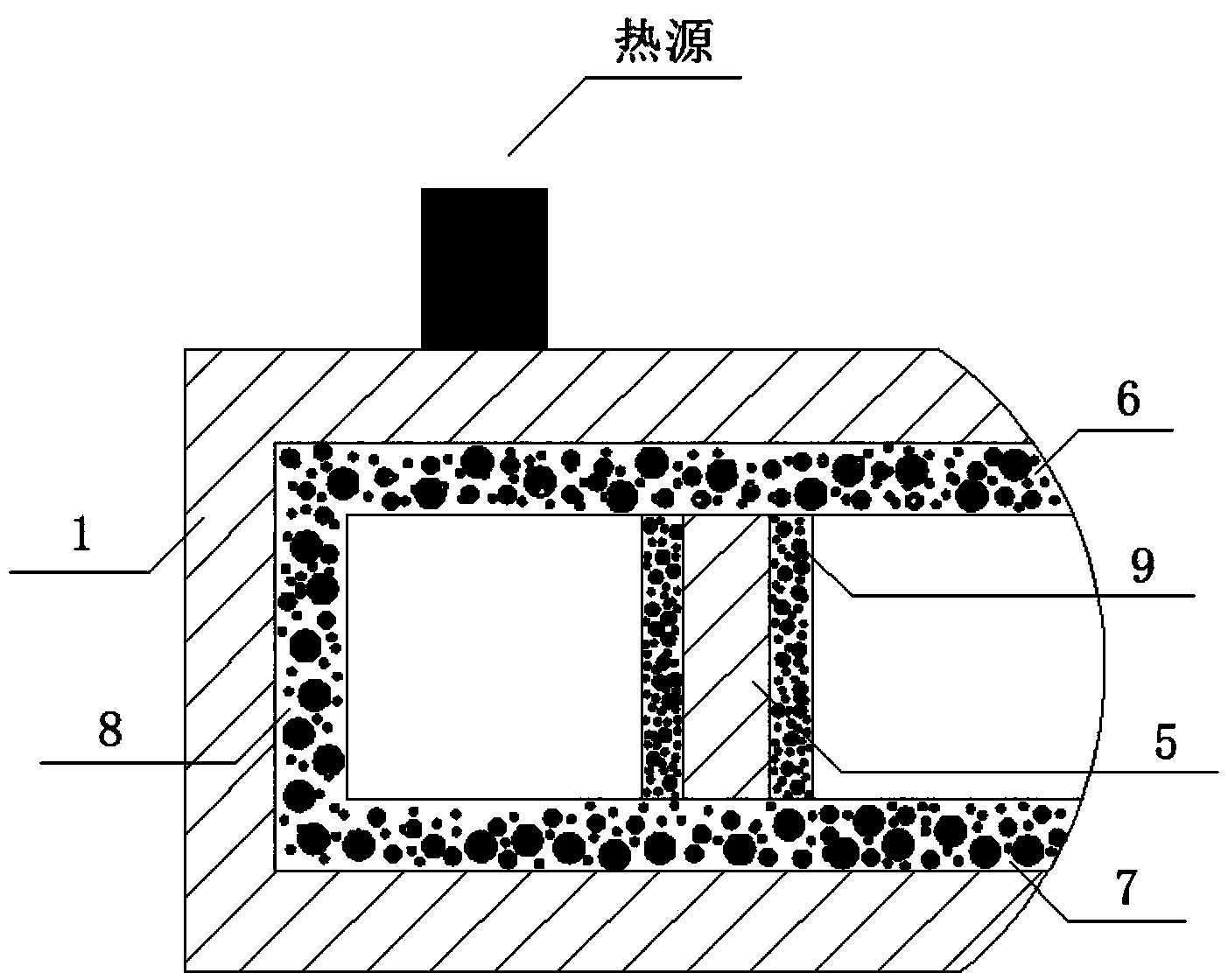

[0011] combine figure 1 , the high heat flux electronic devices arranged on the surface of the steam chamber heat pipe layer 2 ( figure 1 is referred to as the heat source) through heat conduction to transfer a large amount of heat to the capillary layer 6 on the evaporation surface of the heat pipe layer 2 in the steam chamber. Since the heat pipe layer 2 in the steam chamber is in a state of vapor-liquid two-phase saturation, the liquid working medium that absorbs heat vaporizes rapidly, accompanied by As the pressure increases, the gas working medium moves toward the capillary layer 7 on the condensation surface. When it reaches the capillary layer 7 on the condensation surface, it is cooled by the cold plate layer 3 in the middle microchannel, and the gas working medium releases the latent heat of vaporization and turns into a liquid again. Driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com