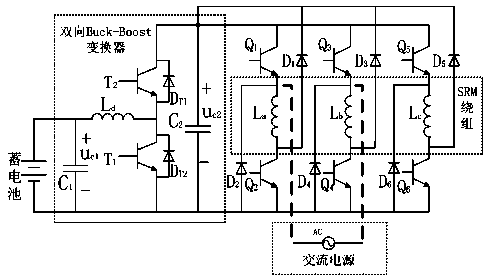

Topological structure of power converter of electric car switch reluctance motor

A technology of switched reluctance motors and power converters, which is applied in motor generator control, electric vehicles, and conversion of AC power input to DC power output. , reduce pollution, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

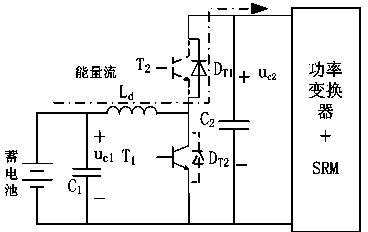

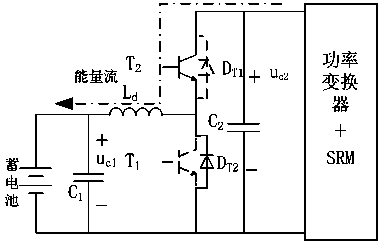

Embodiment 1

[0015] Embodiment 1: Add a bidirectional Buck-Boost converter before the asymmetrical half-bridge power converter of the switched reluctance motor; the described bidirectional Buck-Boost converter includes a capacitor C 1 , capacitance C 2 , switch tube T 1 , switch tube T 2 , Freewheeling diode D T1 , Freewheeling diode D T2 and inductance L d ; switch tube T 1 The collector and switch tube T 2 The emitter is connected to the switching tube T 2 The collector is the positive output terminal, the switching tube T 1 The emitter of the pole is the negative output terminal, the capacitor C2 is connected to the positive input terminal and the negative output terminal, and the switch tube T 1 and switching tube T 2 There are freewheeling diodes D connected in parallel on the collector and emitter respectively. T2 , Freewheeling diode D T1 ; Capacitance C 1 and inductance L d Constitutes an LC type filter, the inductance L d One end is connected to the switch tube T 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com