Motor inner stator and its manufacturing process

A manufacturing process and internal stator technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problem of low stator full slot rate in the motor, difficult winding work, Affect the motor performance and other issues, to achieve the effect of easy material management, good motor performance, and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

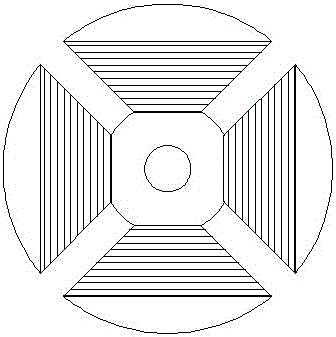

[0028] Such as Figure 3 ~ Figure 6 As shown, the inner stator of the motor includes an iron core 1 and a winding 2 , the iron core 1 is composed of two half-iron cores 101 , and the winding 2 is wound on the half-iron core 101 . The half-core 101 has a cylindrical hub unit 101c, and a shaft hole 101d is arranged in the center of the cylindrical hub unit 101c, and a plurality of winding spokes 101b are uniformly distributed on the circumferential outer surface of the cylindrical hub unit 101c. In the embodiment, there are two wire-wound spokes 101b. An outer rim unit 101a is provided at the outer end of the winding spoke 101b, and the outer rim unit 101a, the winding spoke 101b and the cylindrical hub unit 101c are integrated; 101d is coaxial, the height of the cylindrical hub unit 101c is half of the height of the outer rim unit 101a, the winding spoke 101b is equal to the height of the outer rim unit 101a, and the two half-cores 101 are staggered to form the core 1 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com