A modified single crystal multi-component positive electrode material and its preparation method

A cathode material and modification technology, applied in the field of new energy material preparation, can solve the problems of complicated preparation process, low volume energy density, poor high temperature cycle performance, etc., and achieve high volume energy density, high degree of monodispersity, compact density and high volumetric energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

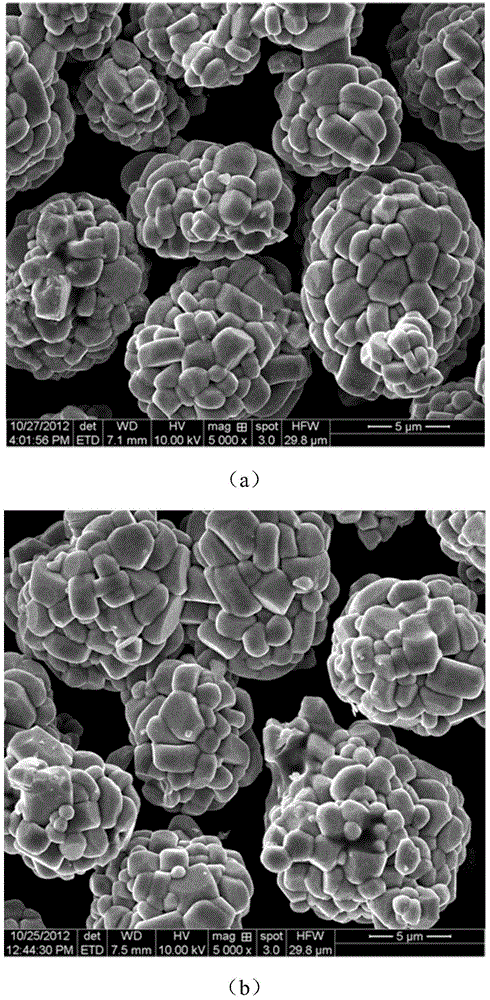

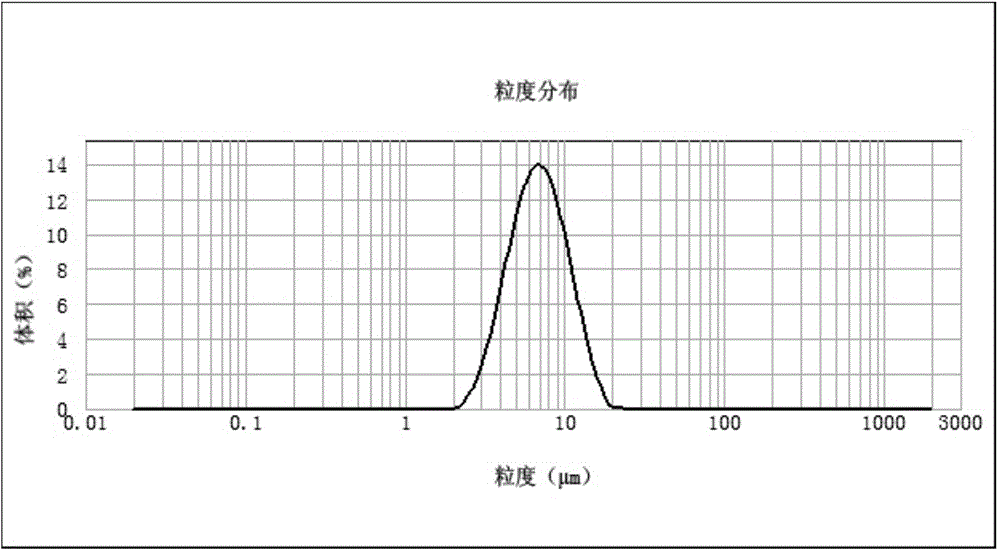

[0031] Dissolve 60g of soluble chitosan in 1kg of water, stir well, then mix 202.18g of LiOH·H 2 O and 10.11g LiF were sequentially added to the above solution, heated and stirred evenly to obtain a mixed sol with uniform particle size distribution; 400g co-precipitated porous precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 and added to the above mixed sol, heated and stirred at 80°C, and slowly evaporated to dryness, so that the mixed sol entered the interior of the porous precursor and evenly adsorbed and deposited on the inner pore surface and outer surface of the porous precursor to obtain the mixture B1; after drying, mix Material A was sintered once at a temperature of 970°C and held for 12 hours to obtain a modified monocrystalline multi-component positive electrode material C1 with a high degree of monodispersity (such as figure 1 (a), (b) shown). The particle size of the monocrystalline multi-element cathode material C1 presents a normal distribution and a high compaction d...

Embodiment 2

[0038] Dissolve 16g of polyvinyl alcohol in 3.68kg of water, stir evenly, then mix 183.8g of LiOH·H 2 O with 23.89g Li 3 PO 4 Add it to the above solution in turn, heat and stir evenly to obtain a mixed sol with uniform particle size distribution; take 400g of co-precipitated porous precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 and added to the above mixed sol, heated and stirred at 80°C, and slowly evaporated to dryness, so that the mixed sol entered the interior of the porous precursor and evenly adsorbed and deposited on the inner pore surface and outer surface of the porous precursor to obtain the mixture B2; after drying, mix The material A was sintered once at a temperature of 980° C. and held for 20 hours to obtain a modified single crystal multi-component positive electrode material C2 with a high degree of monodispersity.

Embodiment 3

[0040] Dissolve 80g of polyvinylpyrrolidone in 2.2kg of water, stir well, then mix 220.56g of LiOH·H 2 O with 2.51gLiH 2 PO 4 Add it to the above solution in turn, heat and stir evenly to obtain a mixed sol with uniform particle size distribution; take 400g of co-precipitated porous precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 And add it to the above mixed sol, heat and stir at 70°C, and slowly evaporate to dryness, so that the mixed sol enters the interior of the porous precursor and is evenly adsorbed and deposited on the inner pore surface and outer surface of the porous precursor to obtain the mixture B3; after drying, mix The material A was sintered once at a temperature of 1100° C. and held for 15 hours to obtain a modified single crystal multi-component positive electrode material C3 with a high degree of monodispersity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com