A soft-pack lithium battery aluminum-plastic film preheating and folding mechanism

A soft-packed lithium battery, aluminum-plastic film technology, applied in battery pack parts, circuits, structural parts, etc., can solve the problems of unsatisfactory bonding effect and limited molding effect accuracy, and achieve good bonding effect and compact structure. , good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] To facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

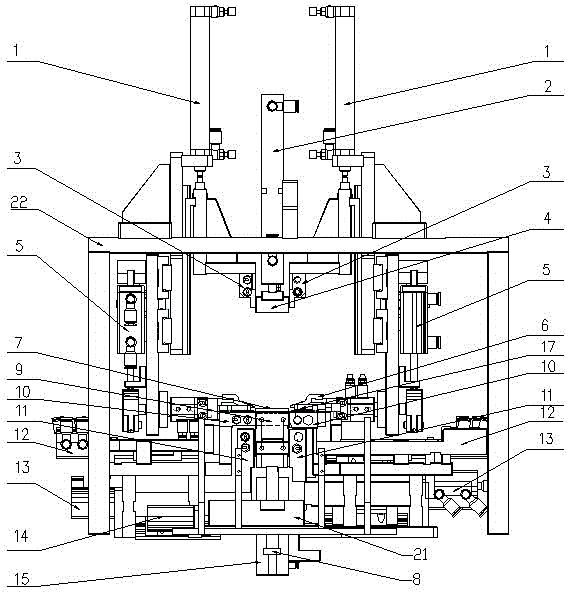

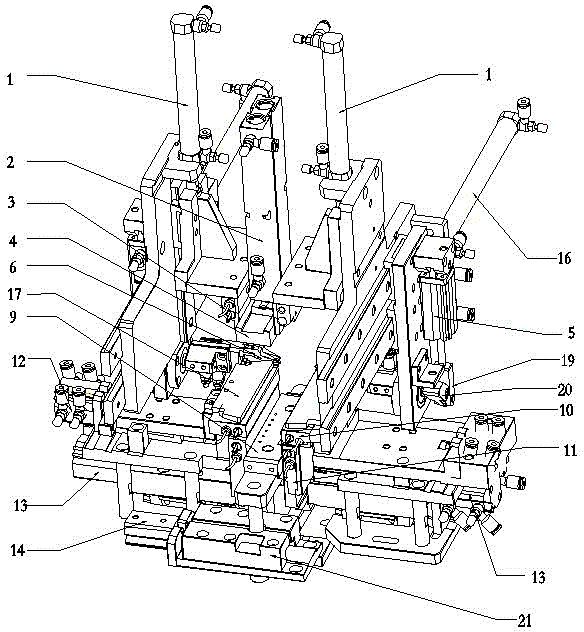

[0014] Specific as attached figure 1 , 2 shown. This embodiment discloses a soft-packed lithium battery aluminum-plastic film preheating and folding mechanism. The overall structure of the mechanism includes a frame. On the driving element three 2 of the movement, a heating block one 3 is arranged on both sides of the pressing fixture, and the heating block one is fixed on the driving element two 1 that can move vertically up and down. The tool is fixed on the driving element 6 15 that can move vertically up and down. The two sides of the fixed fixture are respectively provided with heating block 3 11, heating block 2 10, and cold ironing block 17 from bottom to top. The heating block 3 is fixed on and can move horizontally and horizontally. The driving element 7 13 is on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com