Safety injection tank

A safety injection box and safety injection pipe technology, which is applied in reactors, greenhouse gas reduction, nuclear engineering, etc., can solve the problems of inability to effectively improve the safety of nuclear power plants, the risk of effective cooling of the core, and the low mitigation ability of primary circuit loss of water accidents, etc. problems, to achieve high reliability, improve security, and enhance mitigation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

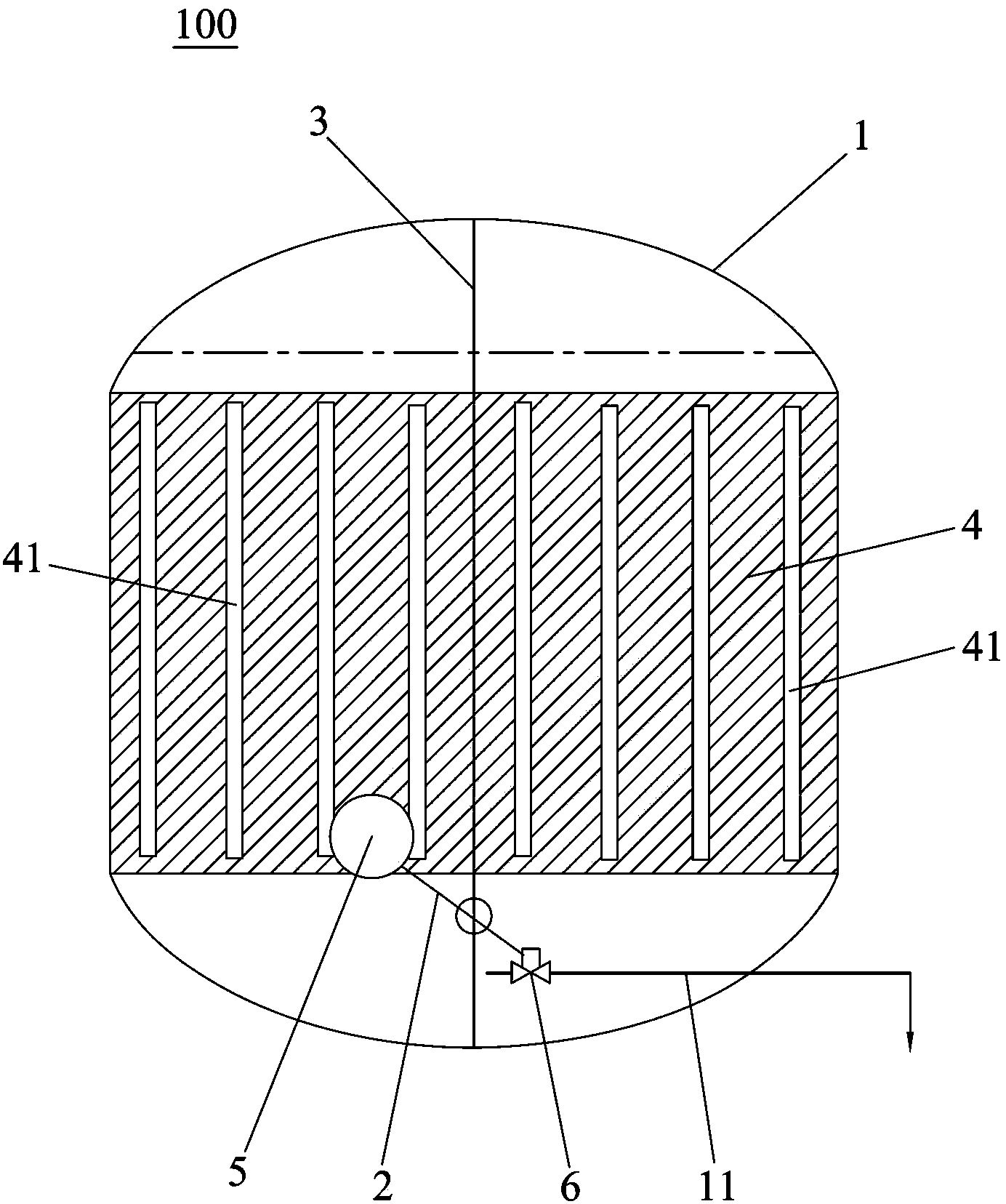

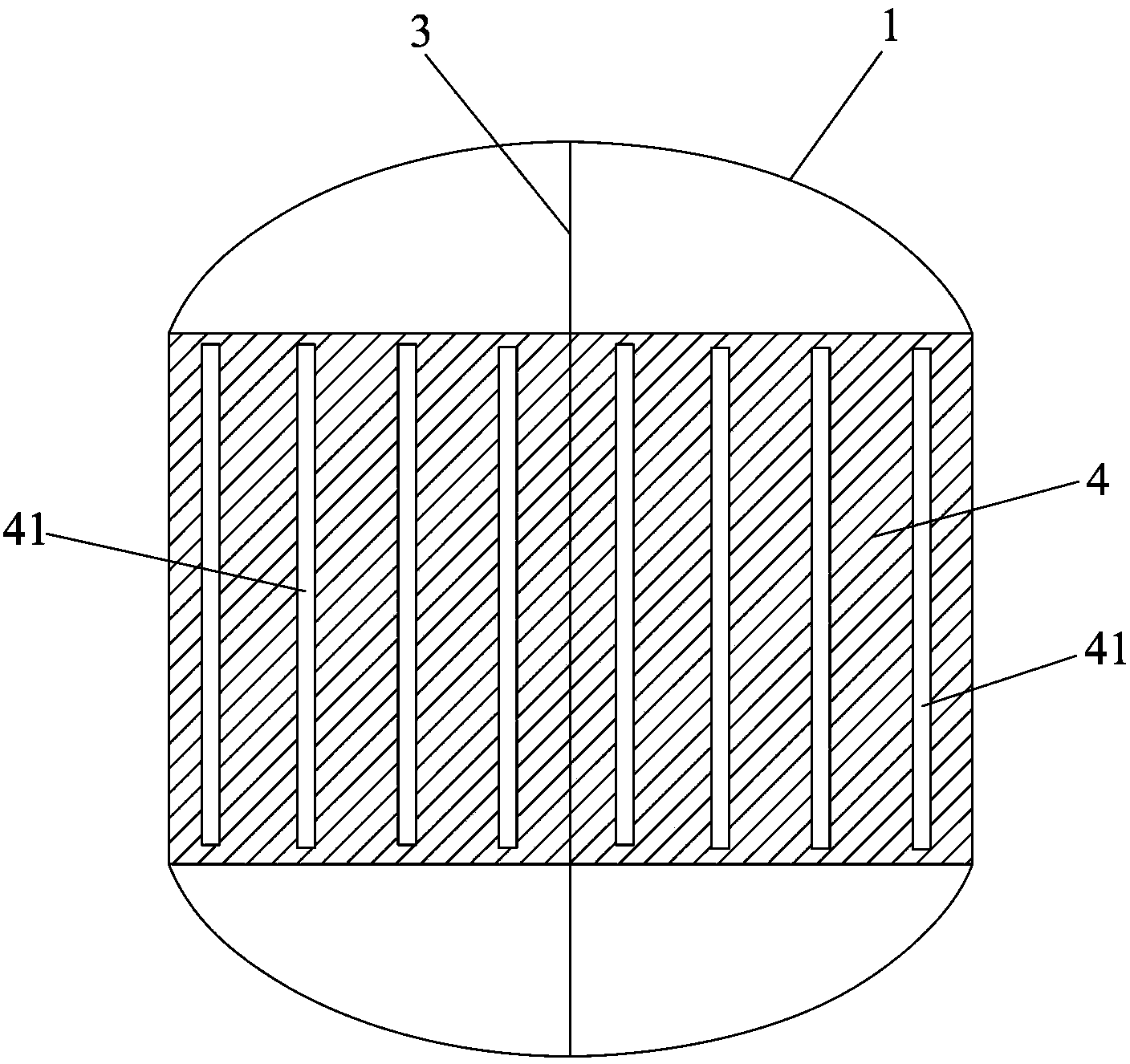

[0021] Such as Figure 1 to Figure 3 As shown, the safety injection tank 100 of the present invention includes a box body 1 for storing boron-containing water and gas, a floating body, a connecting rod 2, a switch, a support member 3 and an anti-rotation device, the anti-rotation device is an anti-rotation partition 4, and the floating body is a floating body The ball 5, the switch is the isolation valve 6. The middle part of the box 1 is cylindrical, and the upper and lower ends are hemispherical; the box 1 is provided with a safety injection pipe 11 connected to the reactor pressure vessel or the primary circuit of the reactor; the safety injection pipe 11 is usually provided with a control valve (not shown in the figure) , the control valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com