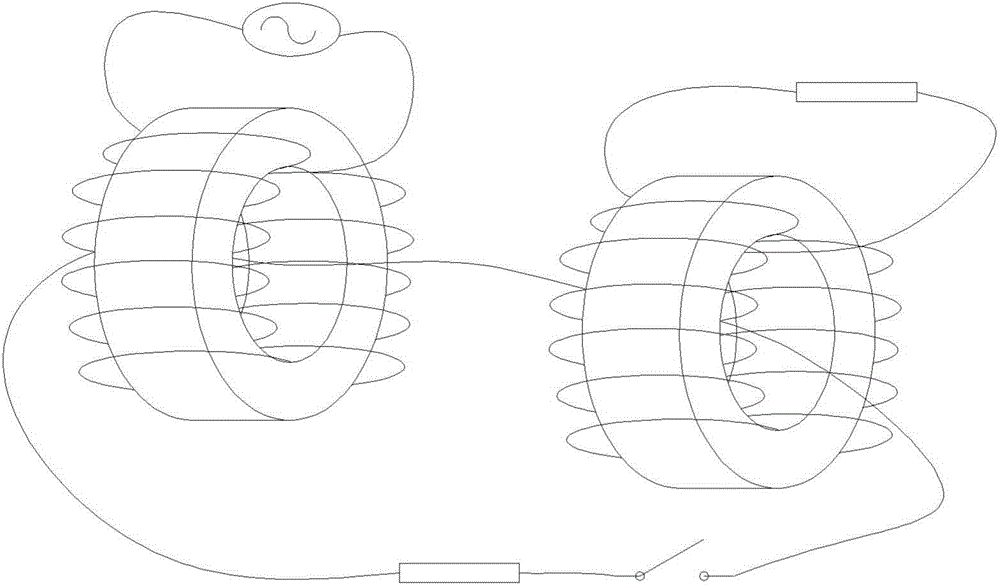

A device and method for measuring fluid conductivity

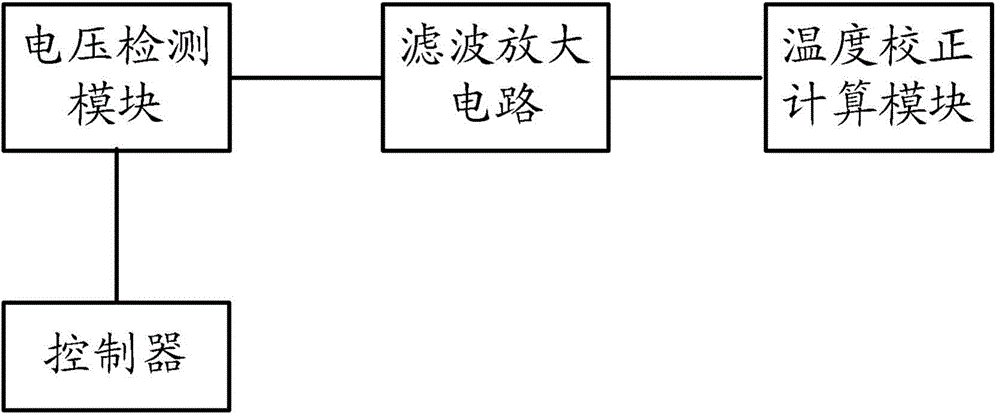

A conductivity and fluid technology, applied in the direction of fluid resistance measurement, material resistance, etc., can solve problems affecting measurement accuracy, signal drift, etc., to achieve the effects of ensuring measurement accuracy, eliminating temperature drift, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0095] Generally, the temperature range of the monitoring fluid for cable formation testing is 25°C to 150°C, the selection range of the winding resistance is between 100 and 1K ohms, and the power supply part of the winding transmitting coil is a sinusoidal excitation voltage with an amplitude of 20v and a frequency of 20kHz to 40khz; preferably 20V, 20kHz AC power supply.

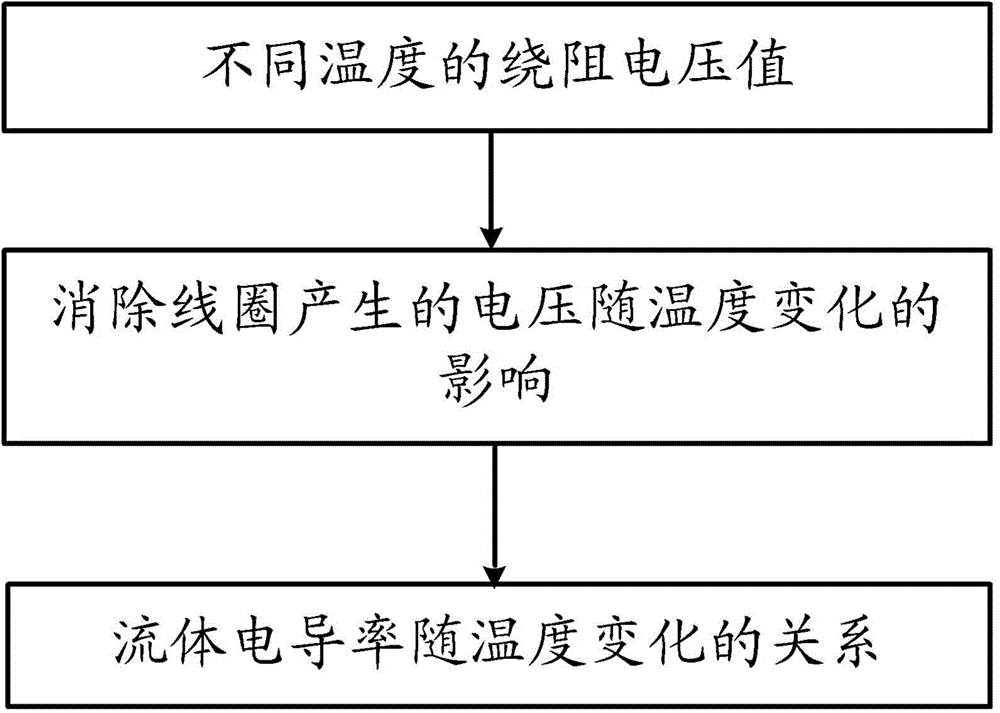

[0096]In this embodiment, 25°C to 150°C can be selected as a sampling point with a temperature interval of 25°C, and 6 sample points are selected, assuming that the relationship between the induced voltage generated by the transmitting coil at both ends of the receiving resistor with temperature can be expressed as Relational formula: f(t)=At 3 +Bt 2 +Ct+D; the coefficients A, B, C, and D in the above formula are obtained by inversion of f(t) values measured at six sample temperature points.

[0097] In order to invert more accurately the relationship between the voltage of the transmitting coil at bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com