Dual soft sealing flat gate valve

A technology of flat gate valve and soft seal, which is applied in the direction of sliding valve, valve detail, valve device, etc., can solve the problems such as no patent documents have been found, and achieve the effect of simple structure, flexible valve control, and low sealing specific pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

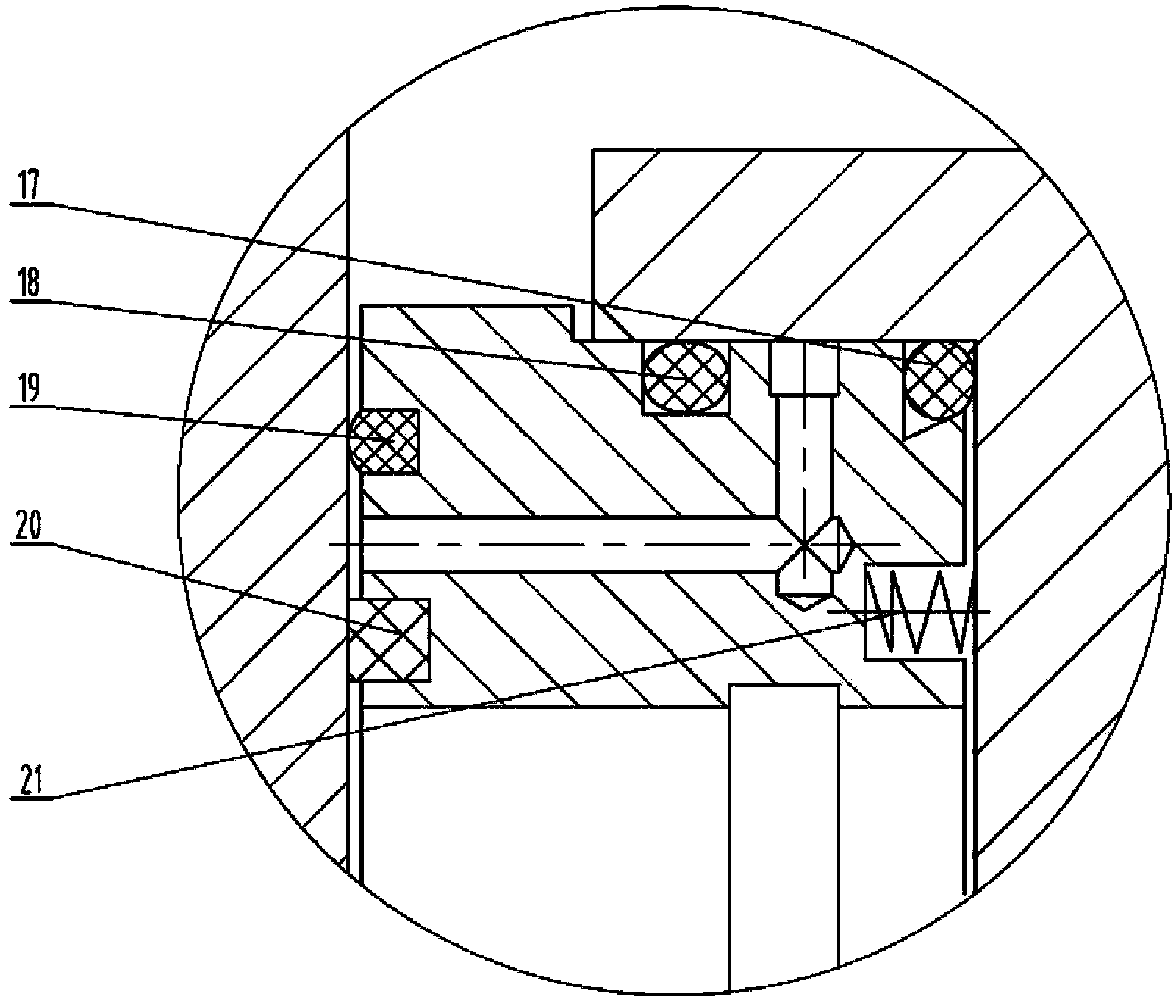

[0019] A double soft-seal flat gate valve, including a valve body 1, a valve cover 6, a gasket 5, a valve stem 4, a packing pressure plate 11, a gate plate 2, a bracket 8 and a valve seat 3, as attached figure 1 As shown, the medium flow channel is coaxially formed in the valve body horizontally, a bonnet is fixed coaxially on the upper end of the valve body, and a sealing gasket is coaxially pressed between the valve body and the bonnet; There is a packing plate coaxially set between the valve stem and the valve cover, and the valve stem can be flexibly rotated and lifted in the valve cover; a stuffing box 12 is coaxially pressed between the valve stem and the valve cover at the lower end of the pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com