Plasma control device and method for blades of wind driven generator

A wind turbine and plasma technology, which is used in the control of wind turbines, wind turbine components, wind turbines, etc., to achieve the effects of fast response, energy enhancement, and flow separation inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

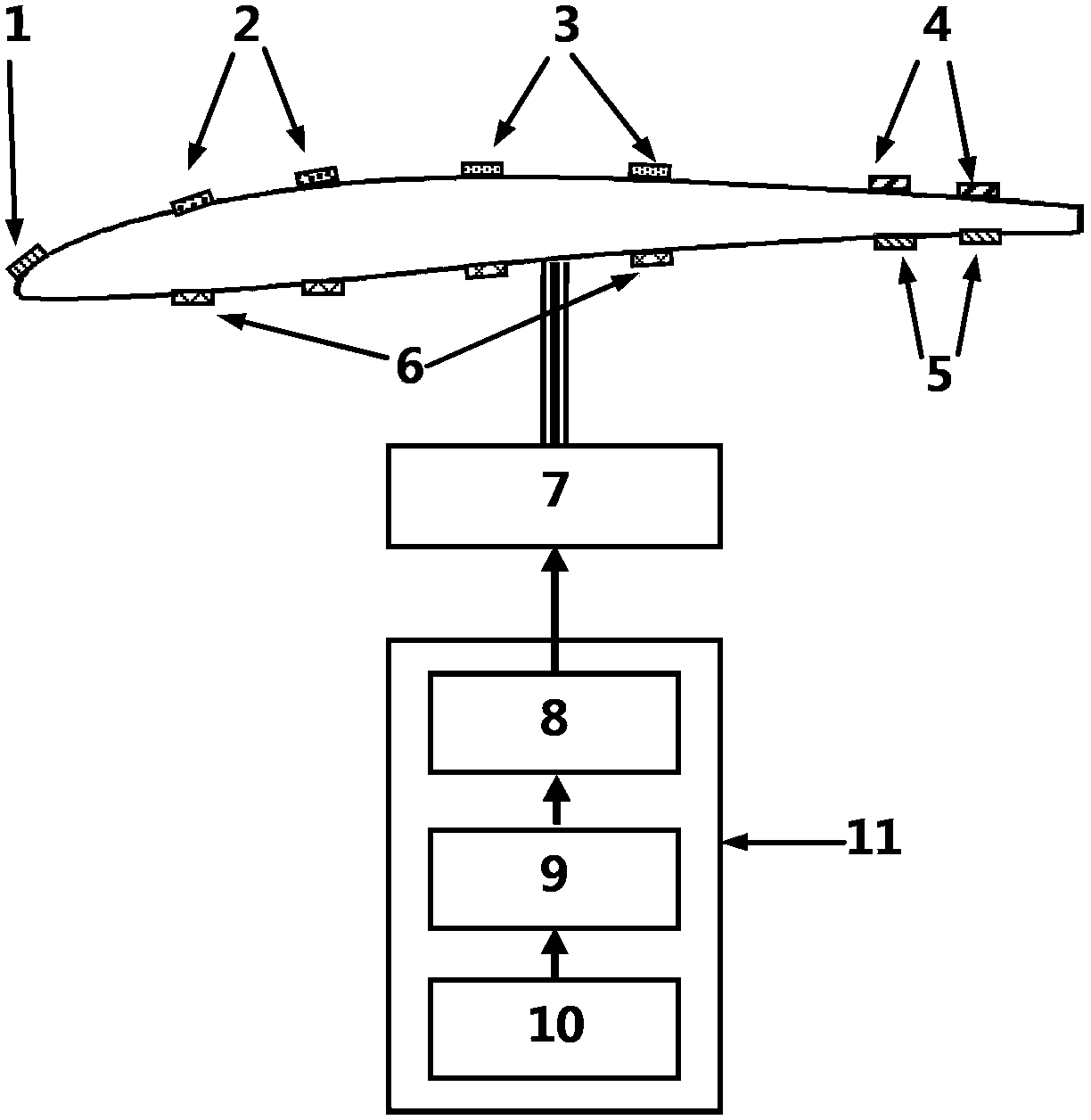

[0056] Example 1: Controlling Flow Separation on the Surface of Wind Turbine Blades

[0057] Step 1. Install the plasma actuator system

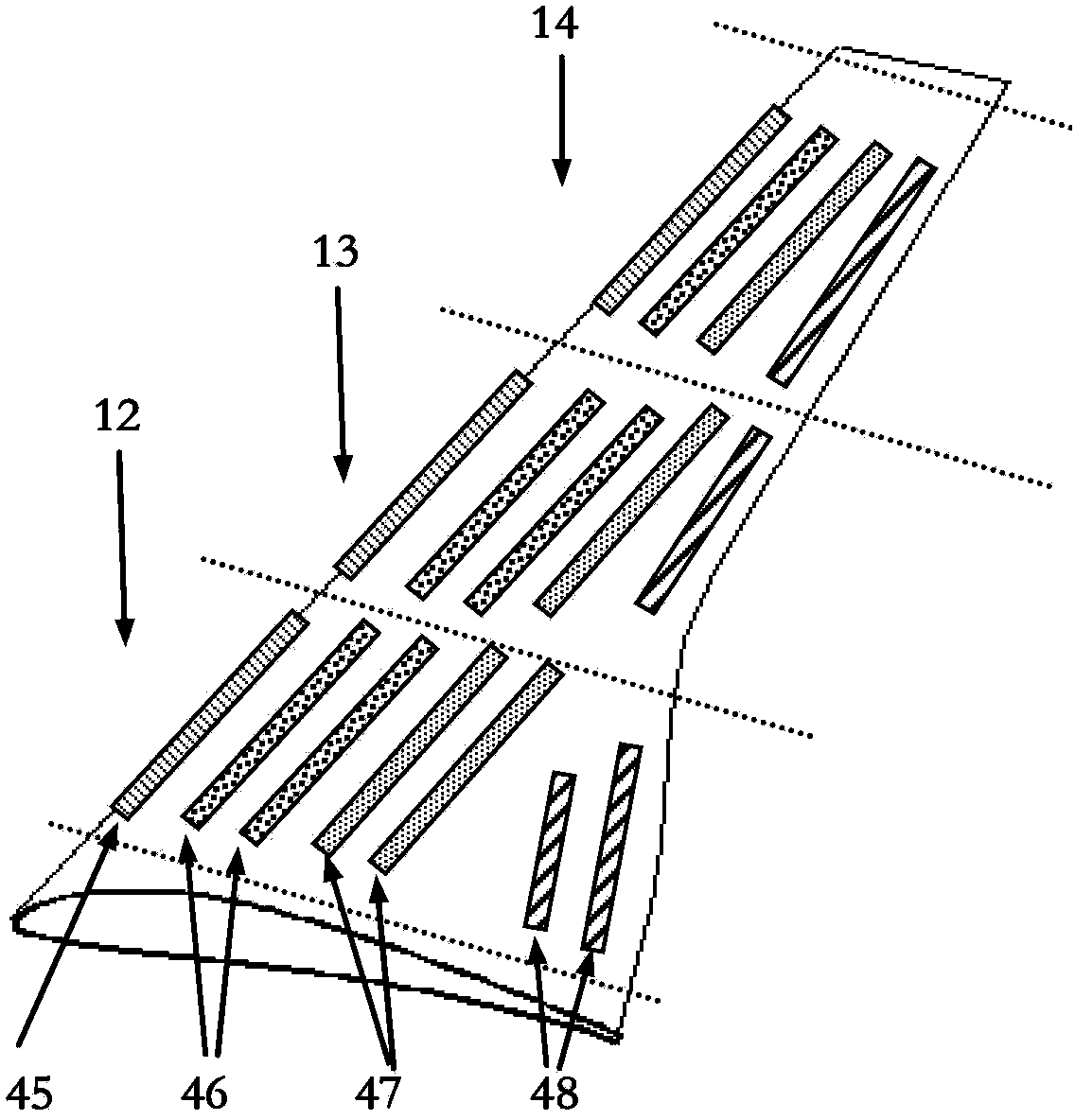

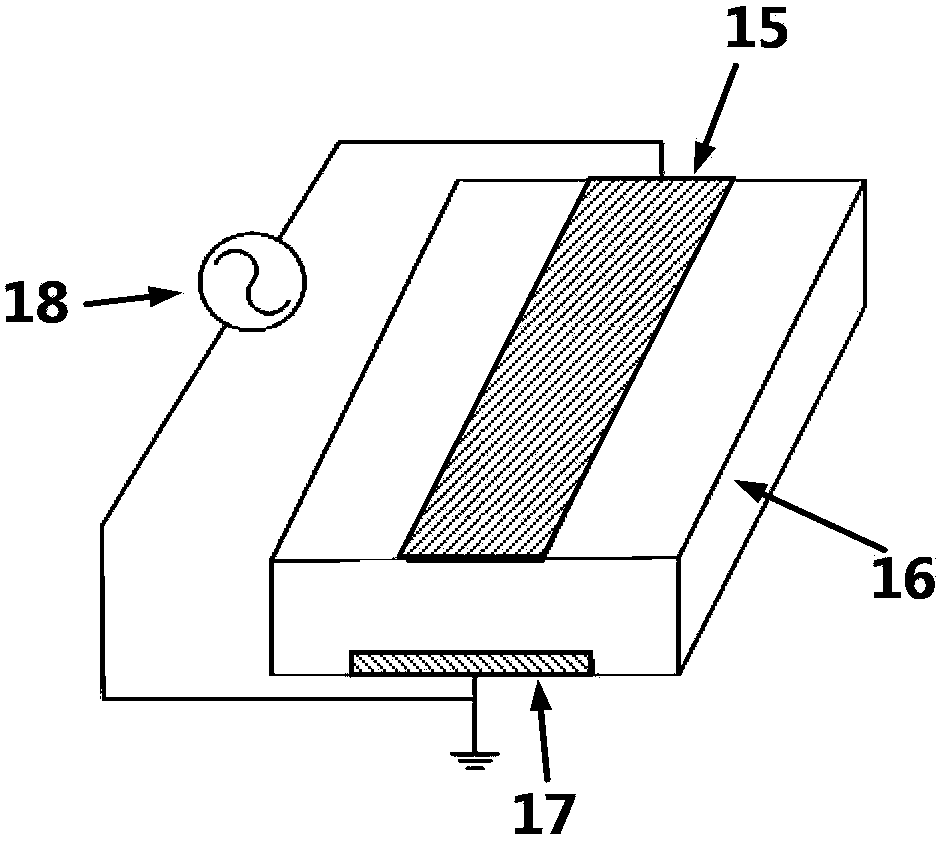

[0058] According to the embodiment, the length of the blade of the wind power generator selected is 39.1m, which is divided into 6 control areas in the radial direction, and the lengths of the 6 control areas from the root of the blade to the tip of the blade are 5m, 5m, 7m, 7m, 7m, 8.1 m; Each control area includes 6 control sub-areas including leading edge 1, front upper surface 2, rear upper surface 3, trailing edge upper surface 4, trailing edge lower surface 5, and lower surface 6; the first The wind turbine blades in the control area do not need to apply flow control, only need to install plasma actuators for anti / deicing control; 20 plasma actuators are evenly installed in control area 1; control areas 2, 3, 4, 1 plasma actuator is arranged in the leading edge control sub-area 1 of 5 and 6; the plasma excitation is arranged at an int...

Embodiment 2

[0066] Embodiment 2: Anti-icing on the surface of wind turbine blades

[0067] The area where the wind turbine is located has just experienced a rainfall, resulting in a rapid increase in air humidity, while the temperature drops in the morning and evening, causing ice to form on the surface of the wind turbine blades. It is necessary to turn on the plasma control system for anti-icing treatment.

[0068] Step 1. Install the plasma actuator system

[0069] The arrangement of the plasma actuator system is the same as Step 1 of Embodiment 1.

[0070] Step 2. Plasma actuator system anti-icing work

[0071] The microprocessor 9 in the control system 11 determines that the surface of the wind turbine blade reaches the freezing condition according to the measurement of the temperature sensor and the humidity sensor, and determines that all the plasma actuators in the 6 control areas on the surface of the wind turbine blade are all turned on for anti-icing, and start Excitation pow...

Embodiment 3

[0072] Embodiment 3: Deicing the surface of wind turbine blades

[0073] The area where the wind turbine is located has experienced continuous low-temperature rainfall for a long time, and the surface of the blades of the wind turbine has icing phenomenon, so it is necessary to turn on the plasma control system for deicing.

[0074] Step 1. Install the plasma actuator system

[0075] The layout of the plasma actuator system is the same as step 1 of the first embodiment.

[0076] Step 2. Plasma actuator system deicing work

[0077]The icing sensor in the plasma control system 11 measures that the icing on the surface of the wind turbine blade reaches 1 mm, and is increasing at a speed of 1 mm / h. The microprocessor 9 of the control system 11 determines 6 control areas on the surface of the wind turbine blade All the plasma exciters are turned on and working, among which the plasma exciters in the control sub-regions of leading edge 1 and front upper surface 2 can be excited by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com