A production process of colored spunlaced nonwoven wiping cloth

A production process and wiping cloth technology, which is applied in the field of textile processing, can solve the problems of nylon fiber performance damage, difficulty in ensuring style, and difficulty in dyeing and finishing, achieve good penetration and level dyeing, and solve monotonous products and simple processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

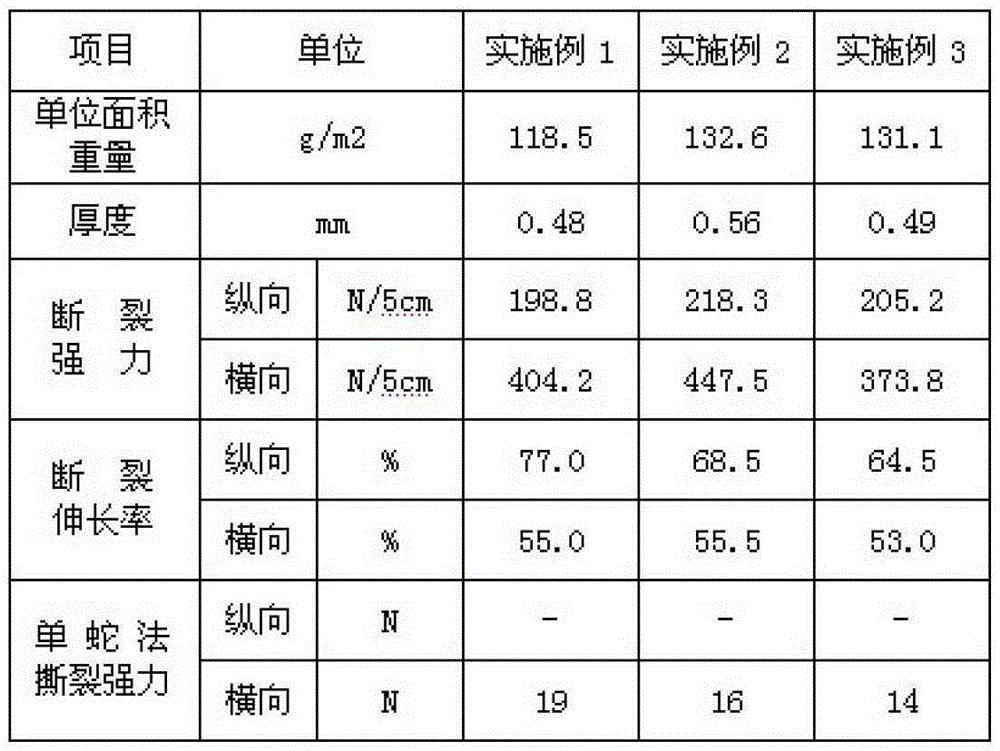

Examples

Embodiment 1

[0046] (1) Opening:

[0047] The drop distance of the beater is 10mm, one hit point is adopted, and the speed of the beater is reduced to make the opening force moderate, and the speed of the beater is 810m / min.

[0048] (2) Combing into a web:

[0049] According to the actual situation, the process parameters of the carding machine for split type microfiber are:

[0050] Main cylinder speed: 740m / min;

[0051] Work roll speed: 75m / min;

[0052] Output speed: 44m / min;

[0053] Carding point spacing of the main cylinder (mm): 0.8, 0.6, 0.5, 0.5, 0.5.

[0054] (3) Spunlace:

[0055] Set the production speed to 12m / min, the pre-wetting pressure to 8Mpa, the initial spunlace pressure to 98MPa, and the subsequent spunlace pressure to 118MPa, 98MPa, and 78MPa respectively.

[0056] (4) Drying:

[0057] Drying is carried out with a hot air penetration dryer, the drying temperature is 120°C, and the fan speed is 1800r / min.

[0058] (5) Dyeing and finishing:

[0059] Pre-setti...

Embodiment 2

[0062] (1) Opening:

[0063] The drop distance of the beater is 13mm, 1 hit point is adopted, and the speed of the beater is reduced to make the opening force moderate, and the speed of the beater is 850m / min.

[0064] (2) Combing into a web:

[0065] Main cylinder speed: 750m / min;

[0066] Work roll speed: 80m / min;

[0067] Output speed: 45m / min;

[0068] Carding point spacing of the main cylinder (mm): 0.8, 0.6, 0.5, 0.5, 0.5.

[0069] (3) Spunlace:

[0070] Set the production speed to 12m / min, the pre-wetting pressure to 8Mpa, the initial spunlace pressure to 100MPa, and the subsequent spunlace pressure to 120MPa, 100MPa, and 80MPa respectively.

[0071] (4) Drying:

[0072] Drying is carried out with a hot air penetration dryer, the drying temperature is 130°C, and the fan speed is 1900r / min.

[0073] (5) Dyeing and finishing:

[0074] Pre-setting (175℃×2min)——padding dyeing solution (two dipping and two padding, liquid loading rate 80-90%)—hot air penetration dryi...

Embodiment 3

[0077] (1) Opening:

[0078] The drop distance of the beater is 15mm, 1 hit point is adopted, and the speed of the beater is reduced to make the opening force moderate, and the speed of the beater is 880m / min.

[0079] (2) Combing into a web:

[0080] According to the actual situation, the process parameters of the carding machine for split type microfiber are:

[0081] Main cylinder speed: 760m / min;

[0082] Work roll speed: 85m / min;

[0083] Output speed: 46m / min;

[0084] Carding point spacing of the main cylinder (mm): 0.8, 0.6, 0.5, 0.5, 0.5.

[0085] (3) Spunlace:

[0086] Set the production speed to 12m / min, the pre-wetting pressure to 10Mpa, the initial spunlace pressure to 102MPa, and the subsequent spunlace pressure to 122MPa, 102MPa, and 82MPa respectively.

[0087] (4) Drying:

[0088] Drying is carried out with a hot air penetration dryer, the drying temperature is 140°C, and the fan speed is 2000r / min.

[0089] (5) Dyeing and finishing:

[0090] Pre-sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com