Method for preparation of three-dimensional ordered macroporous Ce-Zr material by using PMMA as template

A three-dimensional ordered, ce-zr technology, applied in the field of material chemistry, can solve the problems of poor thermal stability, small specific surface area, and no special structure, etc., to achieve excellent heat dissipation performance, large specific surface area, improved catalytic activity and production efficiency rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) According to the molar ratio of Ce ion and Zr ion is 3:1, mix cerium nitrate and zirconium nitrate, then add deionized water to prepare a solution with a concentration of 0.1mol / L;

[0028] (2) According to the mass ratio of metal salt (cerium nitrate and zirconium nitrate): citric acid = 1:1.5, add citric acid to the solution in step (1), and stir at a constant temperature of 800r / min at 30°C for 40 minute;

[0029] (3) According to the mass ratio of PMMA: metal salt (cerium nitrate and zirconium nitrate) = 1:1, add the PMMA template to the solution in step (2) for mixing;

[0030] (4) The mixed solution in step (3) was left to stand at room temperature for 3 hours, and then dried at 90°C for 24 hours to obtain the crude product to remove the water therein;

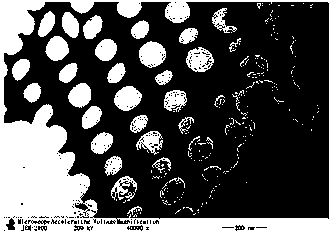

[0031] (5) Heating the crude product obtained in step (4) to 500°C at a heating rate of 2°C / min and then holding the temperature for 3 hours to obtain a three-dimensional ordered macroporous Ce-Zr material; ...

Embodiment 2

[0037] (1) According to the molar ratio of Ce ion and Zr ion is 9:1, mix cerium nitrate and zirconium nitrate, then add deionized water to prepare a solution with a concentration of 0.5mol / L;

[0038] (2) According to the mass ratio of metal salt (cerium nitrate and zirconium nitrate): citric acid = 1:1.2, add citric acid to the solution in step (1), and stir at a constant temperature of 1000r / min at 20°C for 30 minute;

[0039] (3) According to the mass ratio of PMMA: metal salt (cerium nitrate and zirconium nitrate) = 1:2, add the PMMA template to the solution in step (2) for mixing;

[0040] (4) The mixed solution in step (3) was left to stand at room temperature for 4 hours, and then placed at 60°C for 20 hours at a constant temperature to obtain the crude product to remove the water therein;

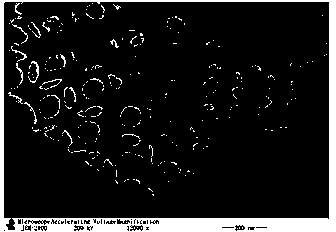

[0041] (5) The crude product obtained in step (4) was heated to 450°C at a heating rate of 2°C / min, and then kept at a constant temperature for 4 hours to obtain a three-dimensiona...

Embodiment 3

[0047](1) According to the molar ratio of Ce ions and Zr ions as 1:1, mix cerium nitrate and zirconium nitrate, and then add deionized water to prepare a solution with a concentration of 1mol / L;

[0048] (2) According to the mass ratio of metal salt (cerium nitrate and zirconium nitrate): citric acid = 1:1, add citric acid to the solution in step (1), and stir at a constant temperature of 300r / min at 90°C for 60 minute;

[0049] (3) According to the mass ratio of PMMA: metal salt (cerium nitrate and zirconium nitrate) = 1:3, add the PMMA template to the solution in step (2) for mixing;

[0050] (4) The mixed solution in step (3) was left to stand at room temperature for 2 hours, then placed at 30°C and dried at a constant temperature for 12 to 24 hours to obtain the crude product to remove the water therein;

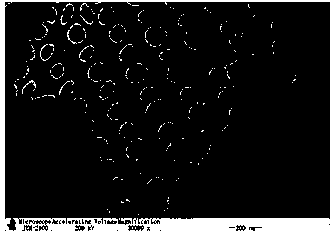

[0051] (5) The crude product obtained in step (4) was heated to 600°C at a heating rate of 2°C / min and then kept at a constant temperature for 2 hours to obtain a three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com