Method for preparing high-grade zinc oxide by utilizing cast iron dust

A zinc oxide, high-grade technology, applied in blast furnaces, blast furnace details, process efficiency improvement, etc., to achieve high economic benefits, increase application range, and improve product grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

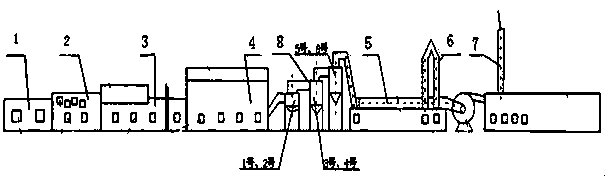

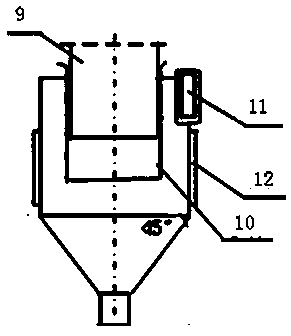

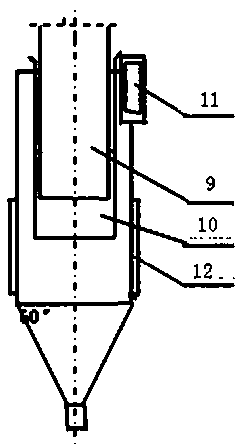

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of 98% zinc oxide from cast iron dust with high content of lead, indium, silver and bismuth

[0038] Select a batch of 2000 kg of cast iron dust, the chemical composition of which is shown in Table 1, and carry out the test according to the following steps:

[0039] Table 1 Chemical composition of dust removal ash

[0040] Element content(%) Element content(%) Element content(%) Element content(%) Zn 25.31 Pb 6.72 F 0.40 Cl 0.60 Fe 22.2 mn 2.1 Si 3.3 Mg 0.72 sn 0.01 Al 1.0 Ca 2.3 C 9.1 In 0.03 Bi 0.02 Ag 0.02 h 2 o 11

[0041] Step a: Mix the dedusted ash with 1000 kg of powdered anthracite coal and 300 kg of lime in a mixer for 10 minutes to achieve a uniform mixture, transport it to a briquetting machine and press it into a 5 cm briquette, and dry it until the water content is about 8%. Powdered anthracite is mixed in as reducing agent.

[0042]Step b: Throw...

Embodiment 2

[0052] Example 2: Preparation of 98% zinc oxide from cast iron dust with low content of lead, indium, silver and bismuth

[0053] Select a batch of 2000 kg of cast iron dust, the chemical composition of which is shown in Table 3, and carry out the test according to the following steps:

[0054] Table 3 Chemical composition of dust removal ash

[0055] Element content(%) Element content(%) Element content(%) Element content(%) Zn 45.31 Pb 1.72 F 0.56 Cl 0.42 Fe 17.9 mn 1.2 Si 2.83 Mg 0.57 sn 0.015 Al 1.8 Ca 1.69 C 7.3 In 0.012 Bi 0.013 Ag <0.001 h 2 o 19.2

[0056] Step a: Mix the dedusted ash with 1000 kg of powdered anthracite coal and 300 kg of lime in a mixer for 10 minutes to achieve a uniform mixture, transport it to a briquetting machine and press it into a 5 cm briquette, and dry it until the water content is about 8%. Powdered anthracite is mixed in as reducing agent.

[0057] Step...

Embodiment 3

[0067] Example 3: Preparation of 98% zinc oxide from cast iron dust with moderate lead, indium, silver and bismuth content

[0068] Select a batch of 2000 kg of cast iron dust, the chemical composition of which is shown in Table 1, and carry out the test according to the following steps:

[0069] Table 5 Chemical composition of dust removal ash

[0070] Element content(%) Element content(%) Element content(%) Element content(%) Zn 32.03 Pb 3.72 F 0.51 Cl 0.68 Fe 15.76 mn 2.78 Si 4.1 Mg 0.62 sn 0.013 Al 1.51 Ca 3.12 C 8.45 In 0.024 Bi 0.018 Ag 0.021 h 2 o 9.00

[0071] Step a: Mix the dedusted ash with 1000 kg of powdered anthracite coal and 300 kg of lime in a mixer for 10 minutes to achieve a uniform mixture, transport it to a briquetting machine and press it into a 5 cm briquette, and dry it until the water content is about 8%. Powdered anthracite is mixed in as reducing agent.

[0072] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com