Cold rolling lubricant for titanium and titanium alloy strips

A cold-rolling lubricant, titanium alloy plate technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of difficult rolling efficiency, and achieve the effect of facilitating annealing treatment, reducing the degree of damage, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

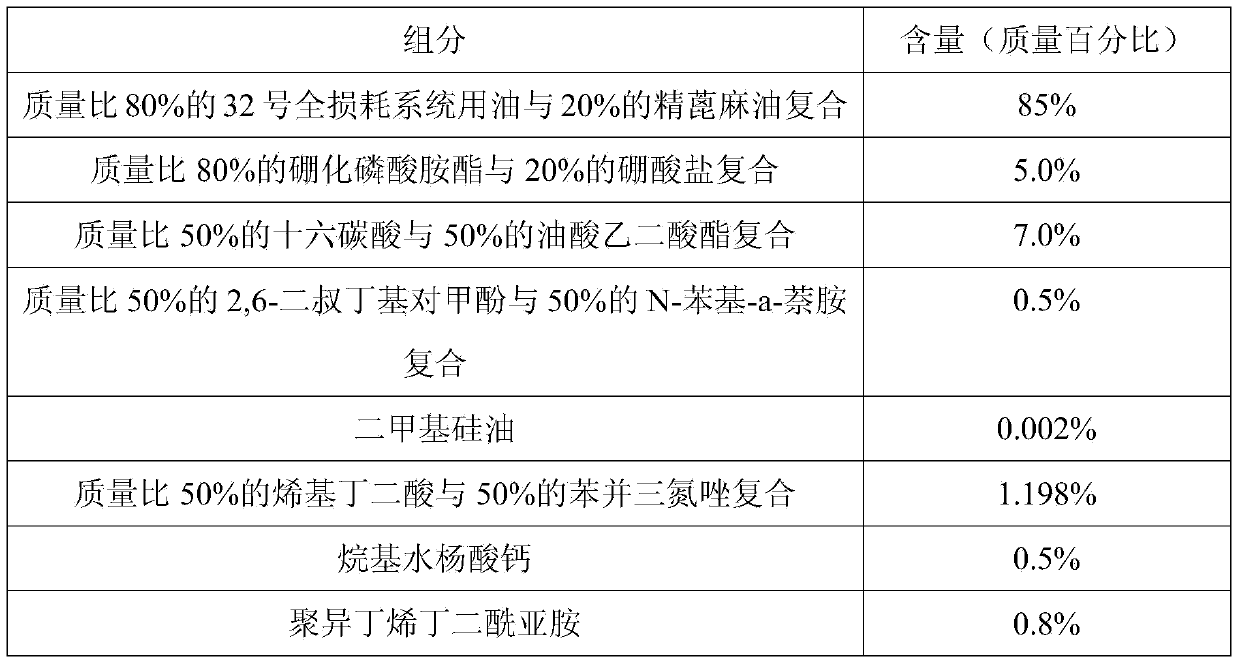

[0017] The following components are blended according to mass percentage:

[0018] components

[0019] The sum of the above components is 100%.

Embodiment 2

[0021] The following components are blended according to mass percentage:

[0022] components

[0023] The mass ratio of 75% No. 32 total loss system oil is compounded with 25% refined castor oil

[0024] The sum of the above components is 100%.

Embodiment 3

[0026] The following components are blended according to mass percentage:

[0027]

[0028] The sum of the above components is 100%.

[0029] The following are the main physical and chemical indicators of the product of embodiment 3:

[0030] project

[0031] Mechanical impurities, % not greater than

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com