A kind of tetradecaldehyde preparation device

A preparation device, a technology for tetradecyl aldehyde, which is used in the preparation of carbonyl compounds by condensation, chemical/physical/physical chemical processes, organic chemistry, etc., can solve the problem of poor cooling effect, affecting the quality of vitamin A acetate, tetradecaldehyde Problems such as the impact of crude product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

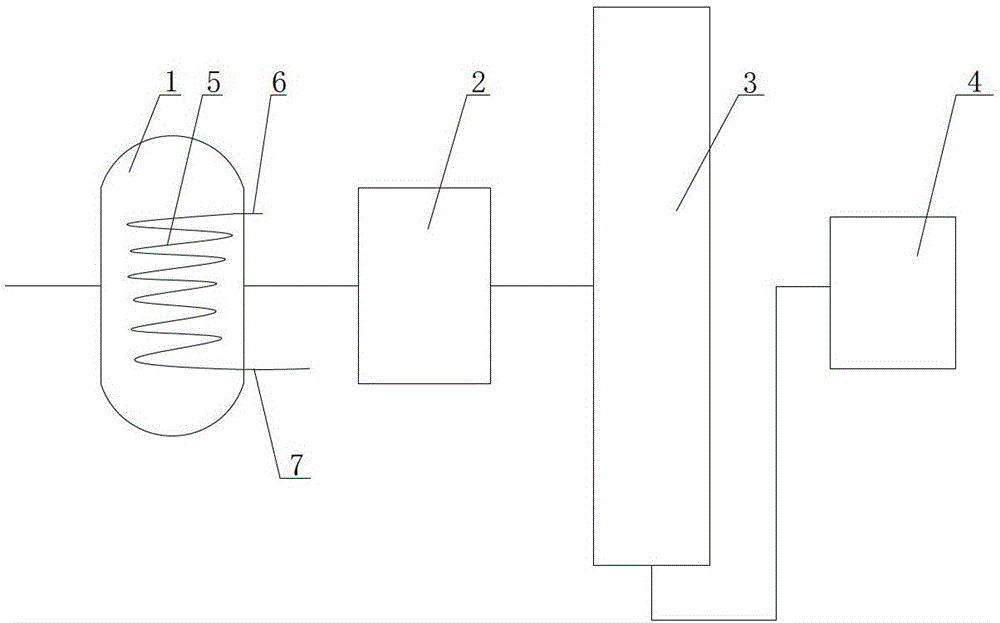

[0013] Tetradecaldehyde preparation device of the present invention comprises the main reactor 1 that reaction raw material is used, the wiped film evaporator 2 that is connected with main reactor 1 pipeline, the rectifying still 3 that is communicated with wiped film evaporator 2 pipelines, and rectifying still 3 Still still 3 pipes are connected to the product collection tank 4. Ionone, methyl chloroacetate, and sodium methoxide are placed in the main reactor 1, and the three are reacted. In order to improve the heat exchange effect of the raw materials in the main reactor 1, an inner tank with brine is provided in the main reactor 1. The coil pipe 5 and the two ends of the inner coil pipe 5 protruding from the main reactor 1 are cooling water inlet 6 and cooling water outlet 7 respectively. The heat generated during the reaction is exchanged in time by using the brine in the inner coil 5 to ensure the orderly progress of the reaction.

[0014] Considering energy saving and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com