Process for recycling desulfurization catalyst from HPF (Hydroquinone, PDS, Ferrous Sulfate) coking desulfuration waste liquid

A technology of coking desulfurization waste liquid and desulfurization catalyst, which is applied in the direction of physical/chemical process catalysts, catalyst regeneration/reactivation, chemical instruments and methods, etc., can solve the problems of increasing operating costs, and achieve the goal of reducing desulfurization costs and reducing serious pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

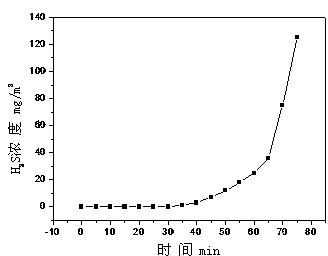

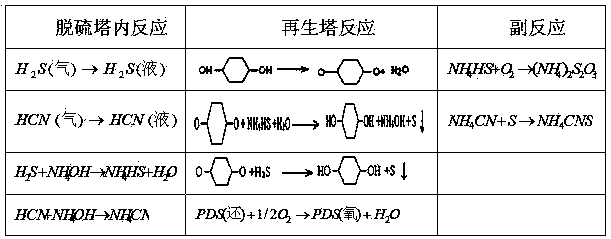

[0023] The desulfurization waste liquid used in this embodiment is the desulfurization waste liquid produced by the coke oven gas in the coking plant using HPF wet method to remove hydrogen sulfide. The process is as follows:

[0024] In the first step, take 500ml of desulfurization waste liquid, and filter the desulfurization waste liquid by means of suction filtration, and filter out 4.8g of insoluble matter;

[0025] In the second step, send the filtrate obtained in the first step above into the catalyst recoverer, and add 50ml of desulfurization catalyst recovering agent to the recoverer at the same time, the C:H:O in the recovering agent is 68.597:14.106:17.297, stir and mix , static, layered;

[0026] The third step is to collect the recovery liquid containing the catalyst in the upper layer of the recovery device in the second step above, and then send it to an evaporative dryer, and carry out evaporation and drying treatment under the condition of 60°C to 90°C, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com