Piston type pneumatic control valve

An air-controlled valve, piston-type technology, applied in the direction of hydraulic brake transmission, etc., can solve the problems of affecting the service life of the air-controlled valve, easy to increase the failure of moving parts, and complex structure of the moving unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

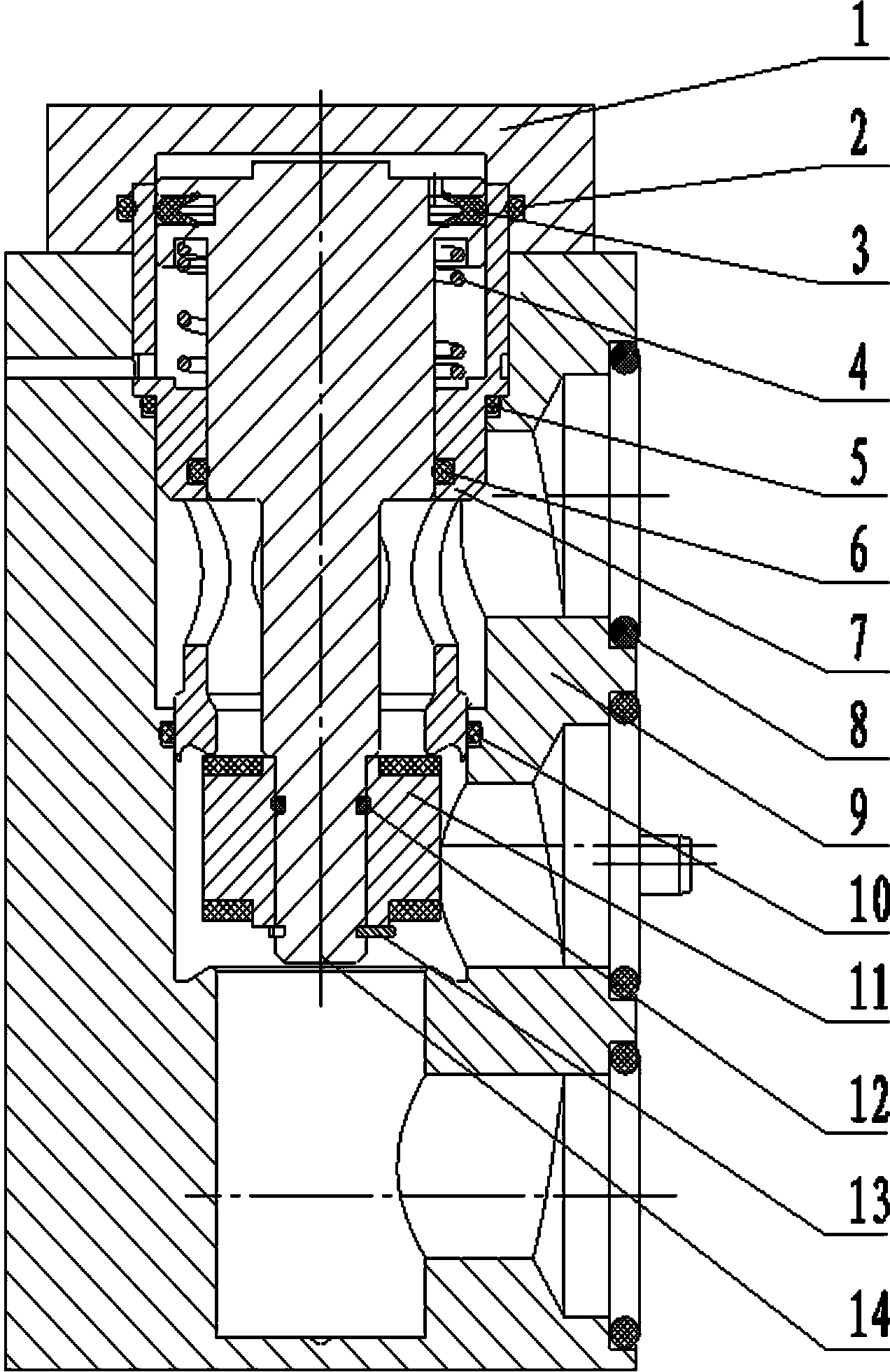

[0136] like Figure 1-6 As shown, a piston-type air control valve includes a valve body 9 with a stepped blind hole, the hole is equipped with a valve seat 7, the valve seat 7 is equipped with a valve stem 14, and the valve stem 14 is provided with a sealing ring groove. A K-shaped sealing ring 3 is installed in the sealing ring groove to realize the sealing at the sealing surface A between the valve seat 7 and the valve stem 14. The right end surface of the valve body 9 is respectively provided with an input port A1, an output port A2 and an exhaust port. Port A3, the stepped blind hole communicates with the input port A1, the output port A2 and the exhaust port A3 respectively, and the valve seat 7 is also installed on it, and the valve vulcanization assembly 11 is installed on the lower part of the valve stem 14, which includes an aluminum block and rubber The upper and lower surfaces of the aluminum block are respectively provided with boss planes, and the rubber parts are...

Embodiment 2

[0142] A piston type air control valve, similar to Embodiment 1, the difference is that the screw 16 is an American screw.

Embodiment 3

[0144] A piston type air control valve, similar to Embodiment 1, the difference is that the screw 16 is an inch screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com