Polarizer peeling machine and peeling method

A polarizer and peeling machine technology, applied in chemical instruments and methods, optics, nonlinear optics, etc., can solve the problems of inability to continuously peel off polarizers, low efficiency, harm to glass substrate circuits and operators, and improve Stripping efficiency, process saving, and easy stripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate and explain the technical solutions of the present invention, but are not intended to limit the scope of the present invention.

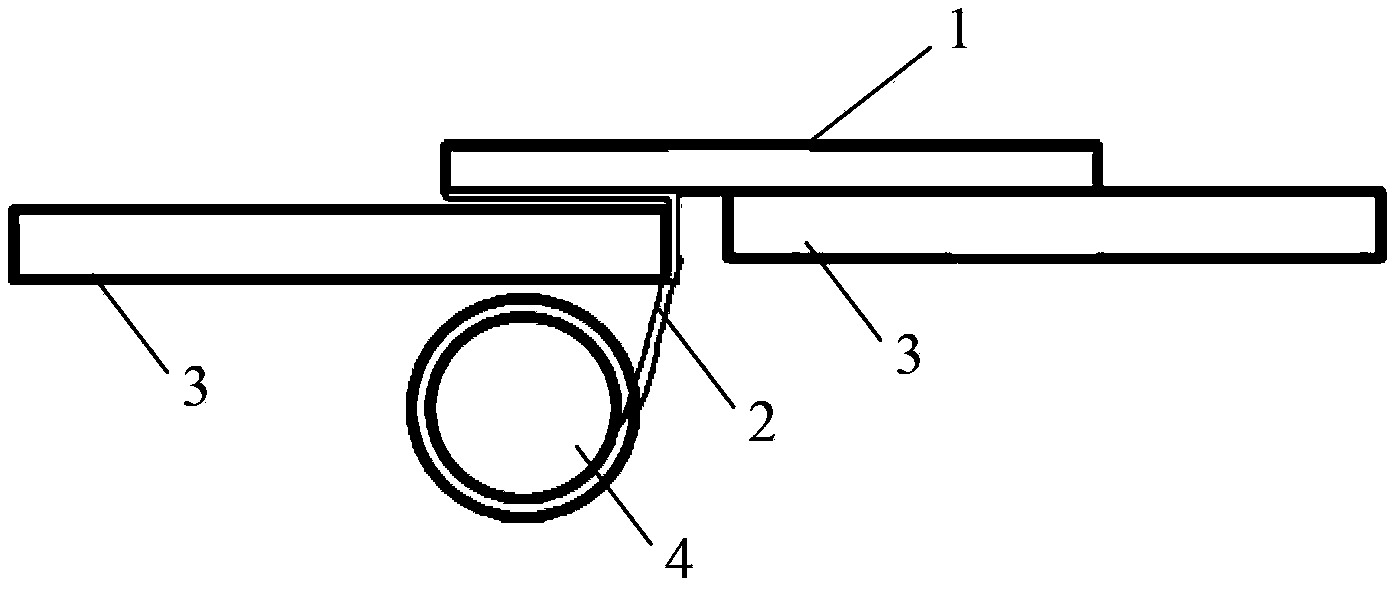

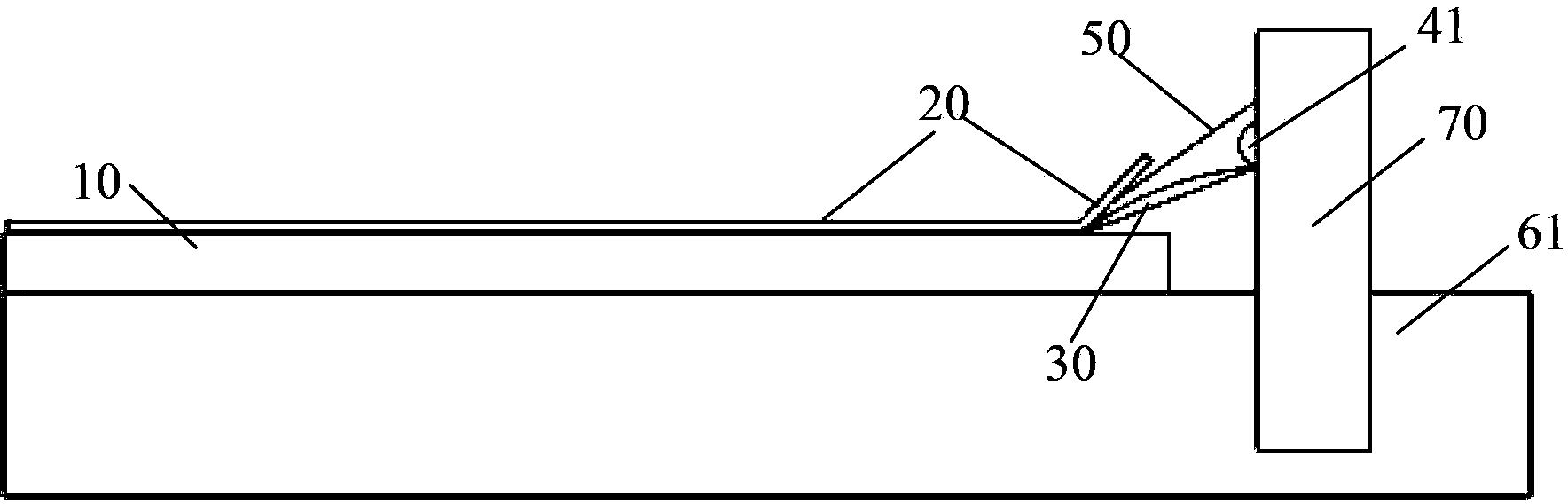

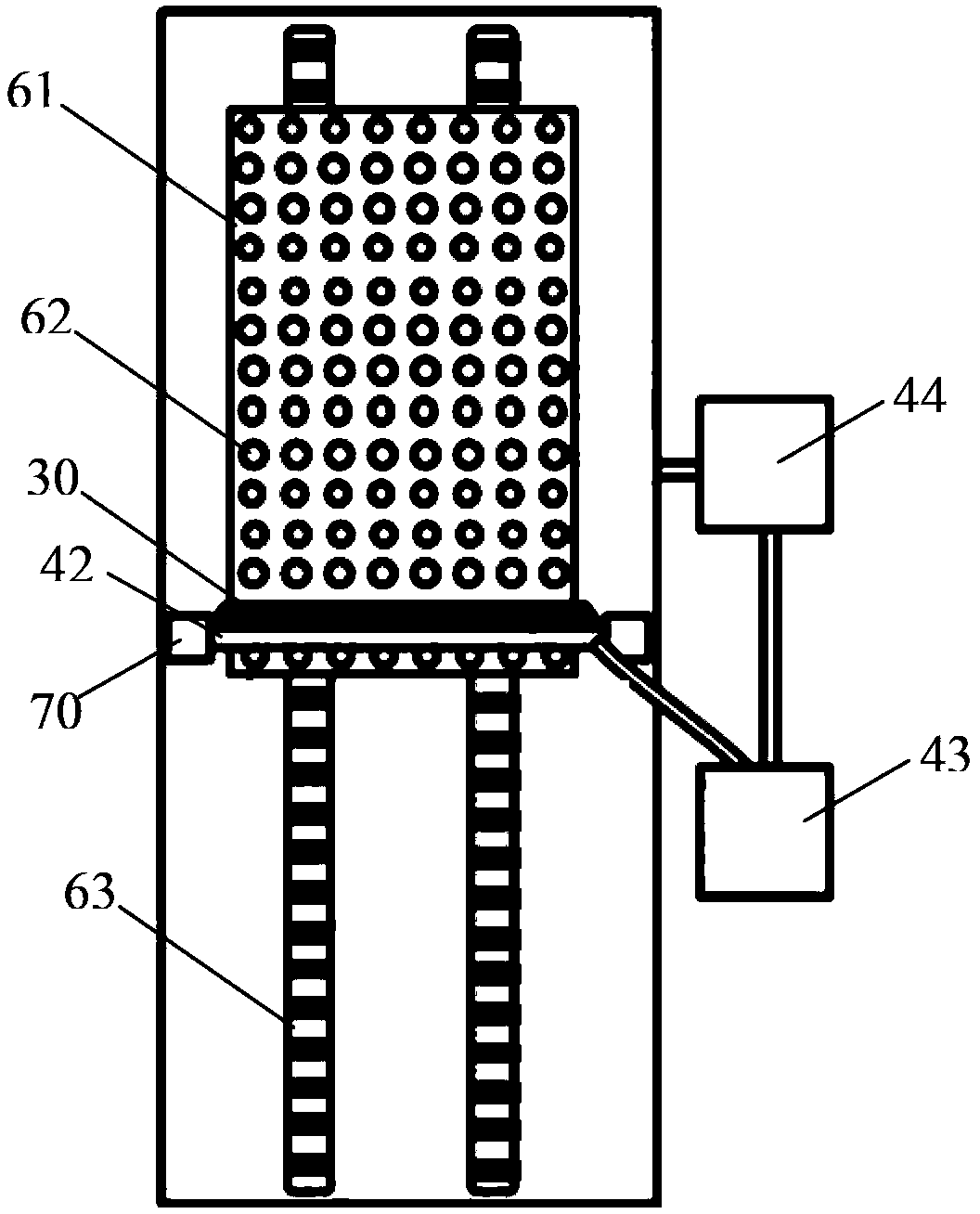

[0030] Such as figure 2 with 3 As shown, a polarizer peeling machine of the present invention includes a peeling blade 30 and a liquid medicine system, the peeling blade 30 is used to peel off the polarizer 20, the liquid medicine system includes a liquid spray nozzle 41, and the peeling blade 30 is used to peel off the polarizer 20. 20 is peeled off, the chemical liquid spray head 41 sprays the adhesive remover between the polarizer 20 and the liquid crystal panel 10 . Preferably, the stripping blade 41 is arranged obliquely so that the liquid medicine can flow between the polarizer 20 and the liquid crystal panel 10 along the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com