Automatic flame cutting machine for square and round continuous casting billets

A flame cutting machine and continuous casting billet technology, applied in gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as accidents, inability to cut billets, adverse effects of billet preheating, etc., and achieve energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

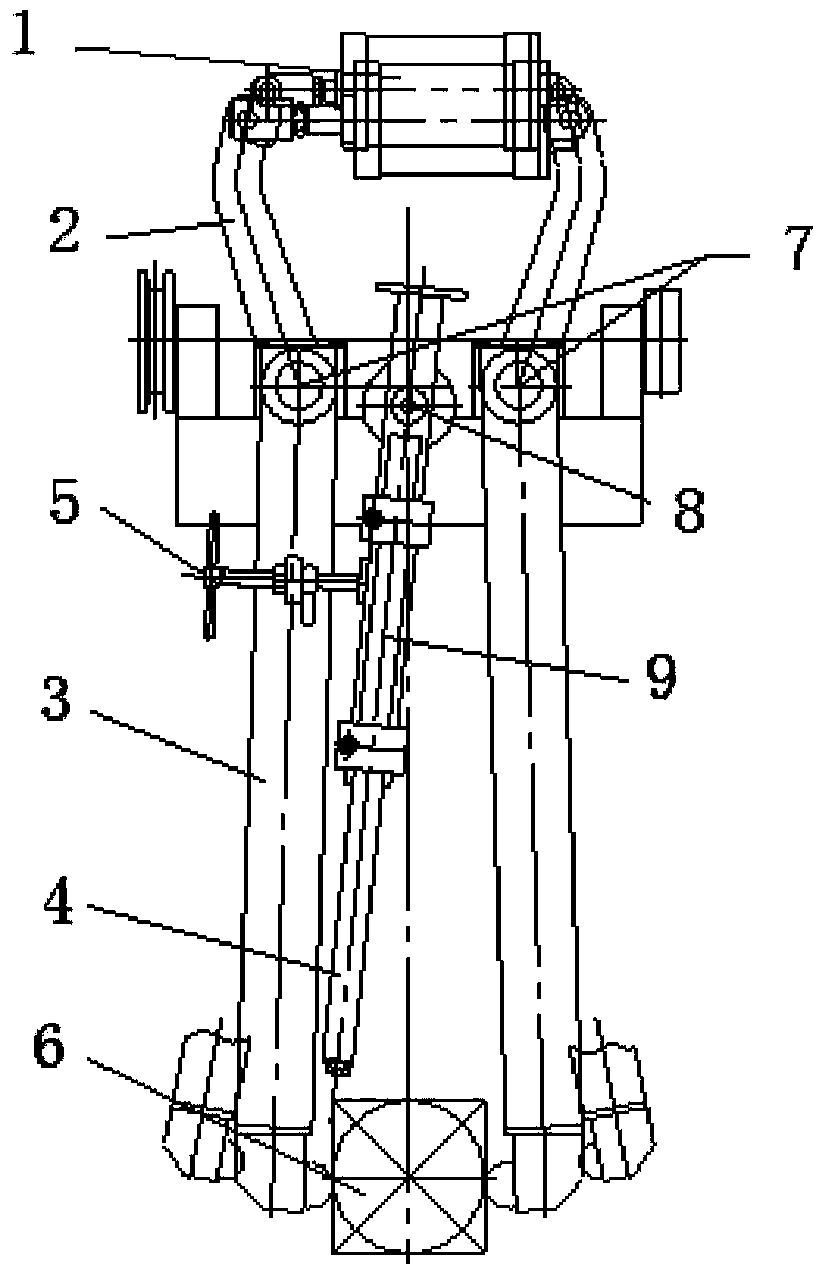

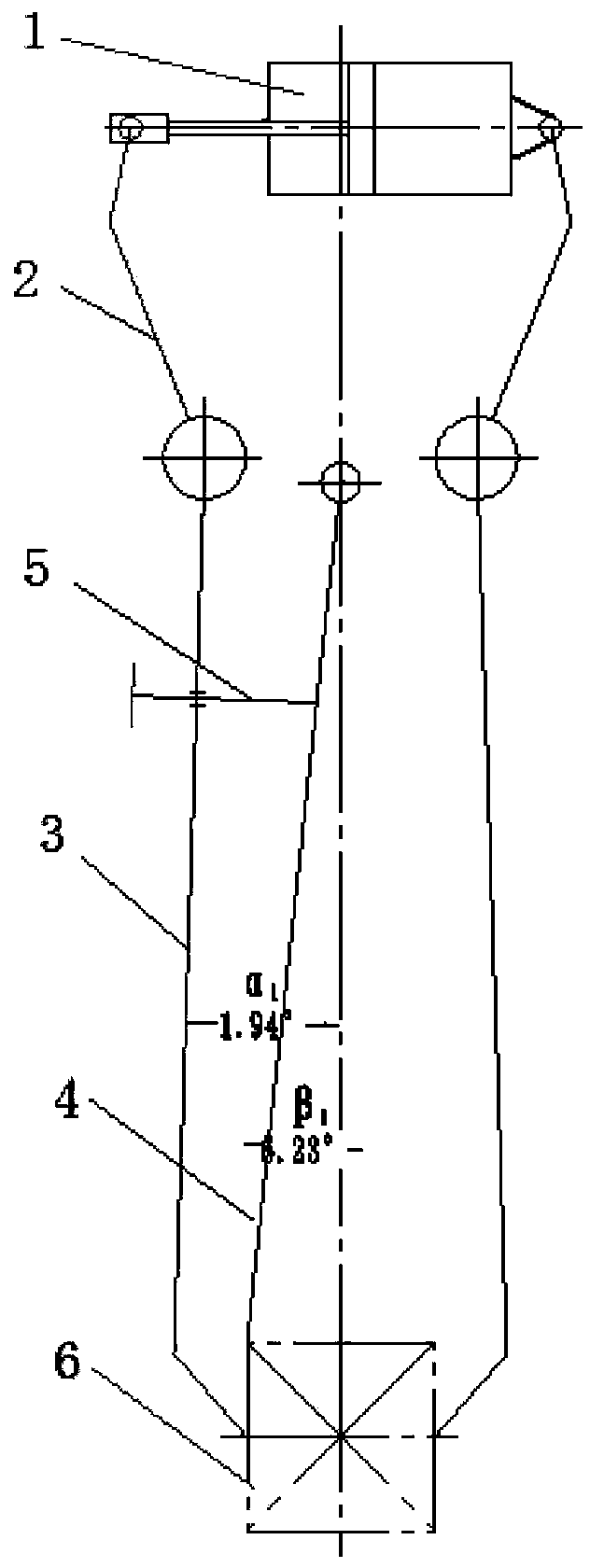

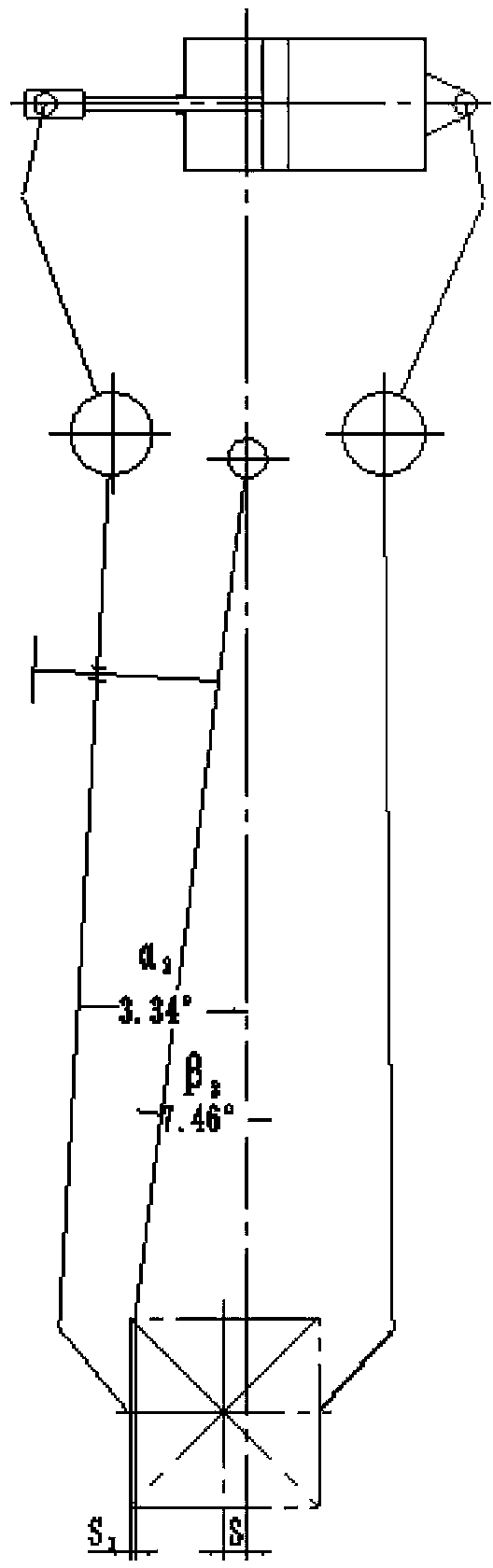

[0025] see image 3 - Fig. 4, the automatic flame cutting machine for square and round continuous casting slabs of the present invention includes two synchronous clamps and a torch located between the two synchronous clamps. For the sake of brevity, other components on the cutting machine are not shown or described in detail, and these components belong to the conventional technology that is obvious to those skilled in the art.

[0026] The synchronous tongs are used to clamp the slab 6, and the torch 4 is used to cut the slab 6. Each synchronous clamp includes an upper clamp arm 2 connected to a driving part 1 (for example, an air cylinder), a lower clamp 3 for clamping a slab 6, and an upper clamp formed between the upper clamp arm and the lower clamp. Rotating sleeve 7 between. The upper clamp arm 2, the lower clamp 3 and the rotating sleeve 7 are formed into one body. The rotating sleeve 7 is installed on the cutting locomotive body, so that the synchronous clamp can ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com