Enteric drug film coating premixture and preparation method thereof

A technology of film coating and premix, applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, etc., can solve the problems of very high technical requirements, uncertain reaction degree, and large restrictions, and achieve the reduction of active ingredients , improved food safety, good effect of chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

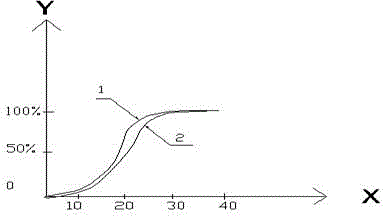

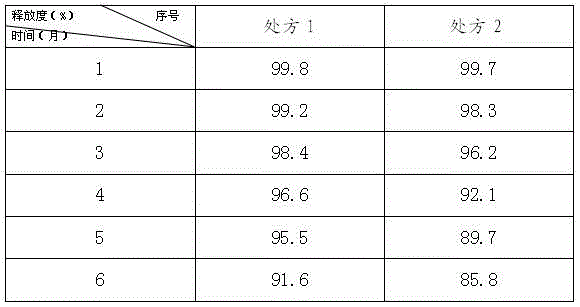

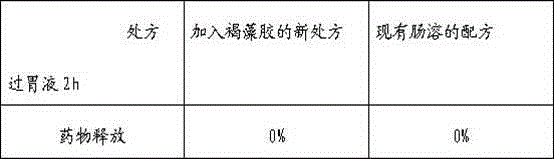

Image

Examples

Embodiment 1

[0019] Embodiment one: the enteric-coated drug film coating premix of the present invention, its composition comprises 40 parts of alginate, 20 parts of talcum powder, 20 parts of triethyl citrate, 5 parts of ethanol whose mass concentration is 99%, above-mentioned The parts are the parts by mass of each component in the premix.

[0020] The method for preparing the above drug film coating premix comprises the following steps, (1) mixing 40 parts of alginate, 20 parts of talcum powder, 20 parts of triethyl citrate, and 5 parts of ethanol with a mass concentration of 99%. Stirring, the above-mentioned parts all represent the mass parts of each component in the coating premix;

[0021] (2) Dry the mixture in the previous step. When the mass percentage of water in the mixture is ≤8%, it is qualified and enters the next step;

[0022] (3) Grind the dried mixture in step (2) until it can pass through a 50-mesh sieve. After sieving, mix it uniformly for 60 minutes to obtain a premi...

Embodiment 2

[0028] Embodiment two: a kind of drug film coating premix developed by the present invention, the premix includes 60 parts of alginate, 40 parts of talcum powder, 30 parts of triethyl citrate, 10 parts of 99% mass concentration For ethanol, the above-mentioned parts are the parts by mass of each component in the premix.

[0029] The premix also includes 10 parts by mass of silica gel, and the particle size of the silica gel is at least 320 mesh.

[0030] The method for preparing the above drug film coating premix comprises the following steps: (1) 60 parts of alginate, 40 parts of talcum powder, 30 parts of triethyl citrate, 10 parts of ethanol with a mass concentration of 99%, 10 parts The silica gel is mixed and stirred, and the above-mentioned parts represent the mass parts of each component in the coating premix;

[0031] (2) Dry the mixture in the previous step. When the mass percentage of water in the mixture is ≤8%, it is qualified and enters the next step;

[0032] (...

Embodiment 3

[0037] Embodiment 3: A kind of pharmaceutical film coating premix developed by the present invention comprises 50 parts of alginate, 30 parts of talcum powder, 25 parts of triethyl citrate, 8 parts of ethanol with a mass concentration of 99%, 5 parts of Titanium dioxide, the above-mentioned parts are the parts by mass of each component in the premix.

[0038] The premix also includes 20 parts by mass of silica gel, and the particle size of the silica gel is at least 320 mesh.

[0039] The method for preparing the above drug film coating premix comprises the following steps: (1) 60 parts of alginate, 40 parts of talcum powder, 30 parts of triethyl citrate, 10 parts of ethanol with a mass concentration of 99%, 20 parts of The silica gel is mixed and stirred, and the above-mentioned parts represent the mass parts of each component in the coating premix;

[0040] (2) Dry the mixture in the previous step. When the mass percentage of water in the mixture is ≤8%, it is qualified and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com