Method for generating heat through fermentation of pig manure

A pig manure, heat generation technology, applied in the application, animal houses, animal husbandry and other directions, can solve the problem of high equipment investment, achieve the effect of increasing the calorific value, saving labor, and reducing the amount of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

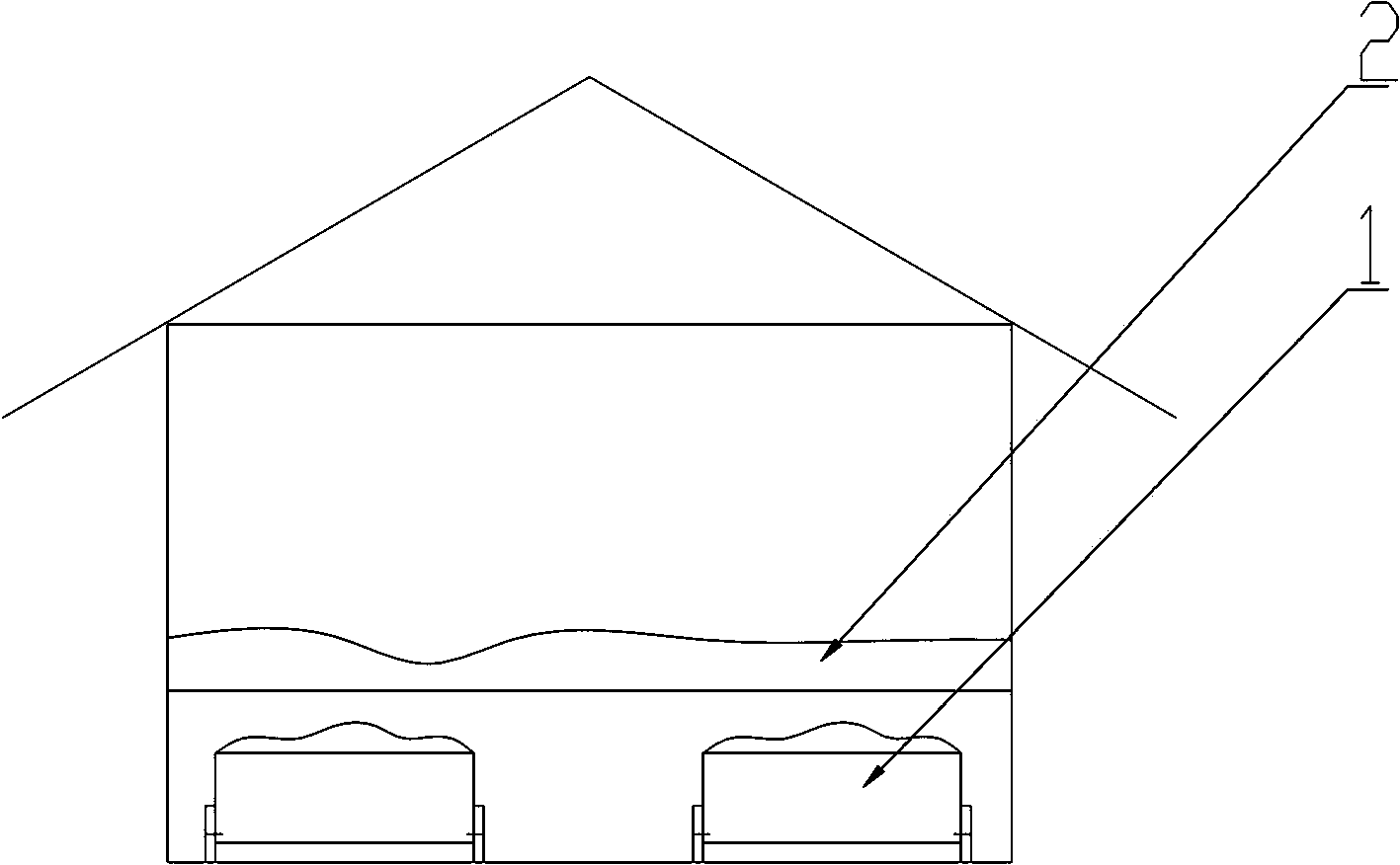

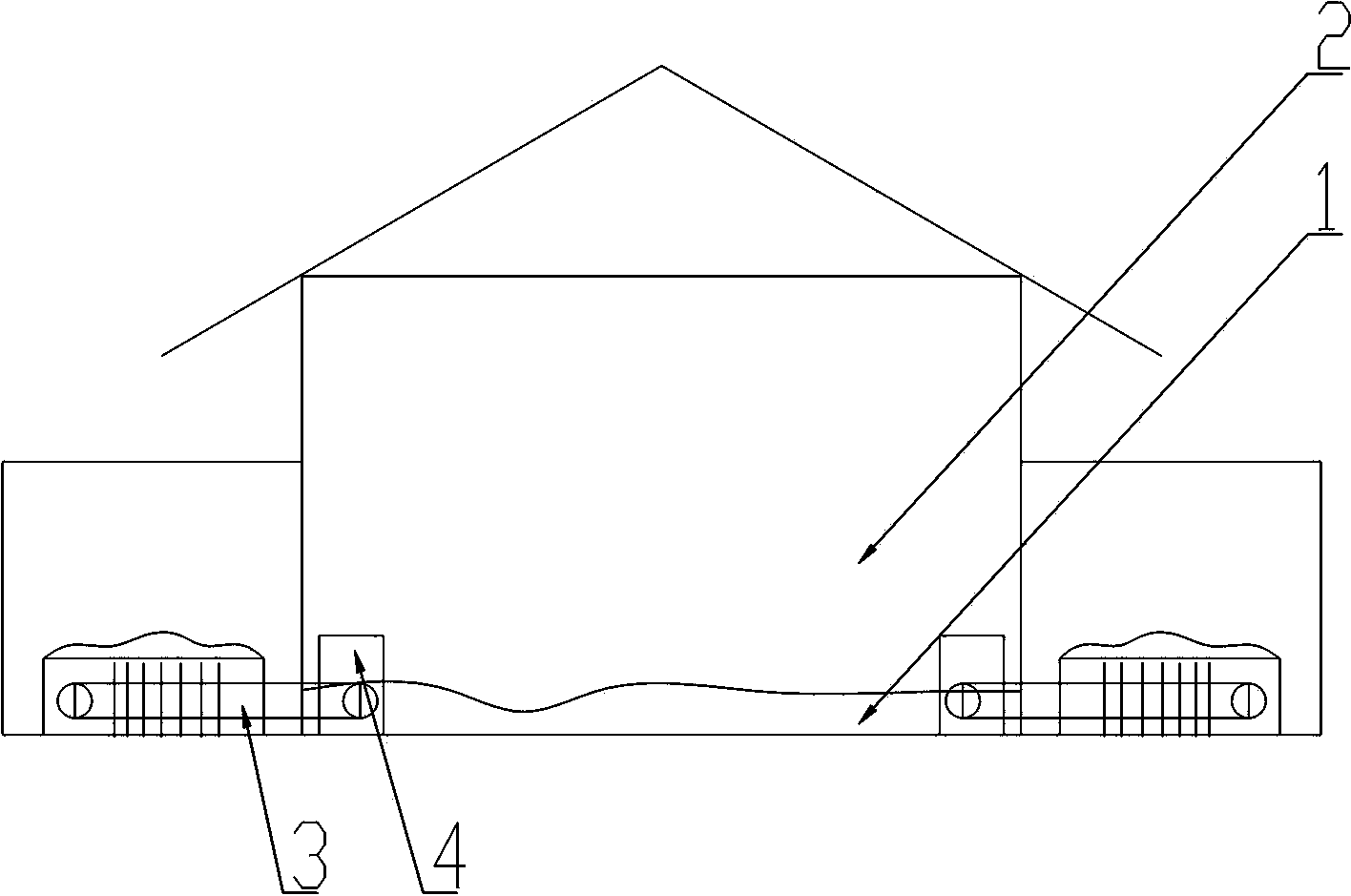

[0029] A method for generating heat by fermenting pig manure, comprising the following steps:

[0030] One, with 4500kg of pig manure in parts by weight, 4500 kg of sawdust, 1800kg of rice bran powder and 0.7kg of fermented bacterial classification, after mixing, add water and insulate and ferment to obtain the original bacteria; the water content is controlled at 25 ~ 60%, and the preferred water content is controlled at 30-45%, since the purpose of the present invention is mainly to obtain the heat generated by the fermentation of pig manure, it is beneficial to reduce the water content to prolong the fermentation time, and reducing the water content can inhibit the growth of miscellaneous bacteria. The fermentation time is 15-40 days, wherein summer is 15-20 days, and winter is 30-40 days.

[0031] Optimized, stack the prepared materials into long strips with a width of 1.5-2 meters and a height of 0.3-0.4 meters, cover them with plastic film, and cover the film with straw ...

Embodiment 2

[0037] 1. Mix 4,800kg of pig manure, 4,800kg of sawdust, 2,000kg of rice bran powder and 1kg of fermented bacteria in parts by weight, add water and heat-preserve and ferment to obtain the original bacteria; the water content is controlled at 40-50%.

[0038] In the fermented strains, the content of thermophilic coprophagous by weight is 50%.

[0039] In the fermented strains, the content of anaerobic and facultative anaerobic thermophilic bacteria is 30% by weight.

[0040] 2. Put 10000kg of pig manure in parts by weight, 10000kg of sawdust and 1000kg of original bacteria into the fermentation bed in the pig house for fermentation after adding water and mixing; the water content is controlled at 35-55%.

[0041] Other parameters are the same as in Example 1. Through the above steps, the temperature of the pig house can be raised by using the heat generated by the fermentation of pig manure. In this example, when the ambient temperature is zero, the temperature inside the pi...

Embodiment 3

[0043] A method for generating heat by fermenting pig manure, comprising the following steps:

[0044] 1. Mix 4900 kg of pig manure, 4900 kg of sawdust, 3000 kg of rice bran powder and 1.1 kg of fermented strains in parts by weight, add water and heat-preserve and ferment to obtain the original bacteria; the water content is controlled at 40-50%.

[0045] In the fermented strains, the content of thermophilic coprophagous by weight is 70%.

[0046]In the fermented strains, the content of anaerobic and concurrently anaerobic thermophilic bacteria is 45% by weight.

[0047] 2. Put 11000kg of pig manure in parts by weight, 11000kg of sawdust and 1000kg of original bacteria into the fermentation bed in the piggery after mixing with water; the water content is controlled at 35-55%.

[0048] Other parameters are the same as in Example 1. Through the above steps, the temperature of the pig house can be raised by using the heat generated by the fermentation of pig manure. When the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com