An electric weeding and scarifying machine

A technology of weeding and scarifying machines and electric motors, which is applied in the fields of land preparation machinery, equipment for eliminating weeds, agricultural machinery and implements, etc. It can solve the problems of unfavorable economic and social sustainable development, unsatisfactory loosening and weeding quality, and expensive mechanical equipment, etc. problem, to achieve the effect of simple and reasonable structure, small footprint and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

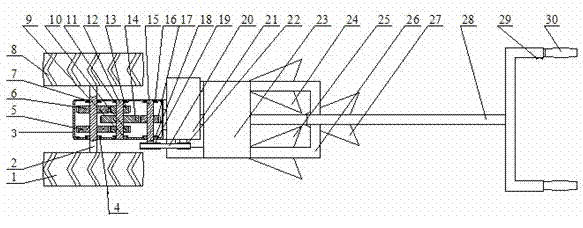

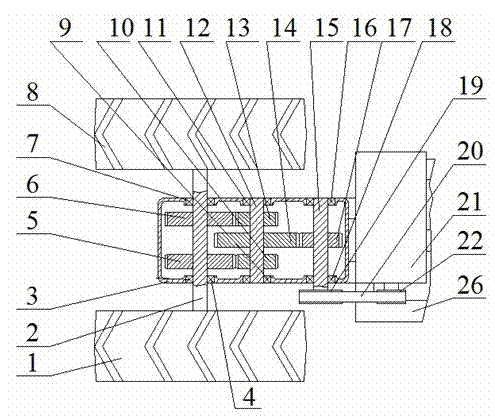

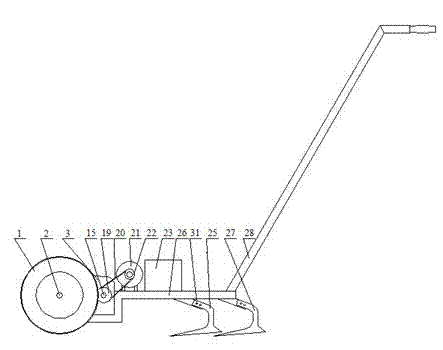

[0022] Embodiment 1: this electric weeding ripper comprises wheel I1, wheel II8, speed reducer 3, motor 21, battery 23, weeding shovel I24, weeding shovel II25, weeding shovel III27, frame 26, handrail 28; wheel I1 and wheel Ⅱ8 is connected together through the axle 2, and the axle 2 is equipped with bearing Ⅵ 4, gear Ⅵ 5, gear Ⅴ 6 and bearing Ⅴ7, and cooperates with the reducer 3 through the bearing Ⅵ 4 and bearing Ⅴ7, and the gear Ⅵ5 and the gear Ⅴ6 are respectively connected with the reducer The gear IV10 and gear III13 in the gear 3 cooperate, the speed reducer 3, the motor 21 and the storage battery 23 are installed on the frame 26, the driven wheel 19 is housed on the speed reducer 3, the drive wheel 22 is housed on the motor 21, and the motor 21 and the speed reducer 3 The power between them is transmitted by the belt 20 between the driving wheel 22 and the driven wheel 19, the battery 23 provides power for the motor 21, and the weeding shovel I 24, the weeding shovel II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com