Winding method and structure for six-groove quadrupole permanent magnet brush motor

A technology of brushed motor and winding method, applied in the shape/style/structure of winding conductors, manufacturing motor generators, electrical components, etc., can solve the problems of high magnetic energy of commutation coils and large coil inductance, and achieve the reduction of magnetic energy , The effect of reducing the coil inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

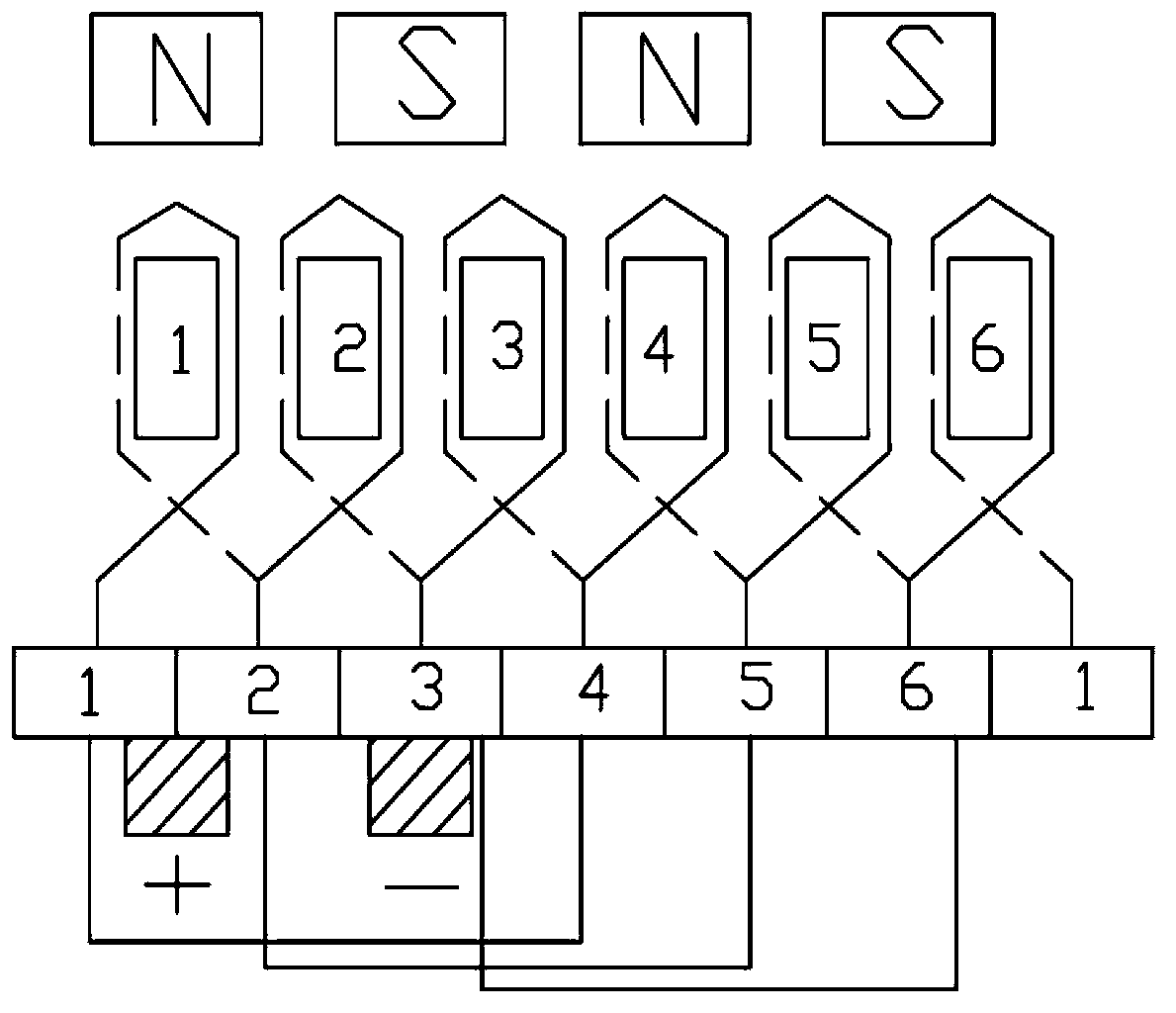

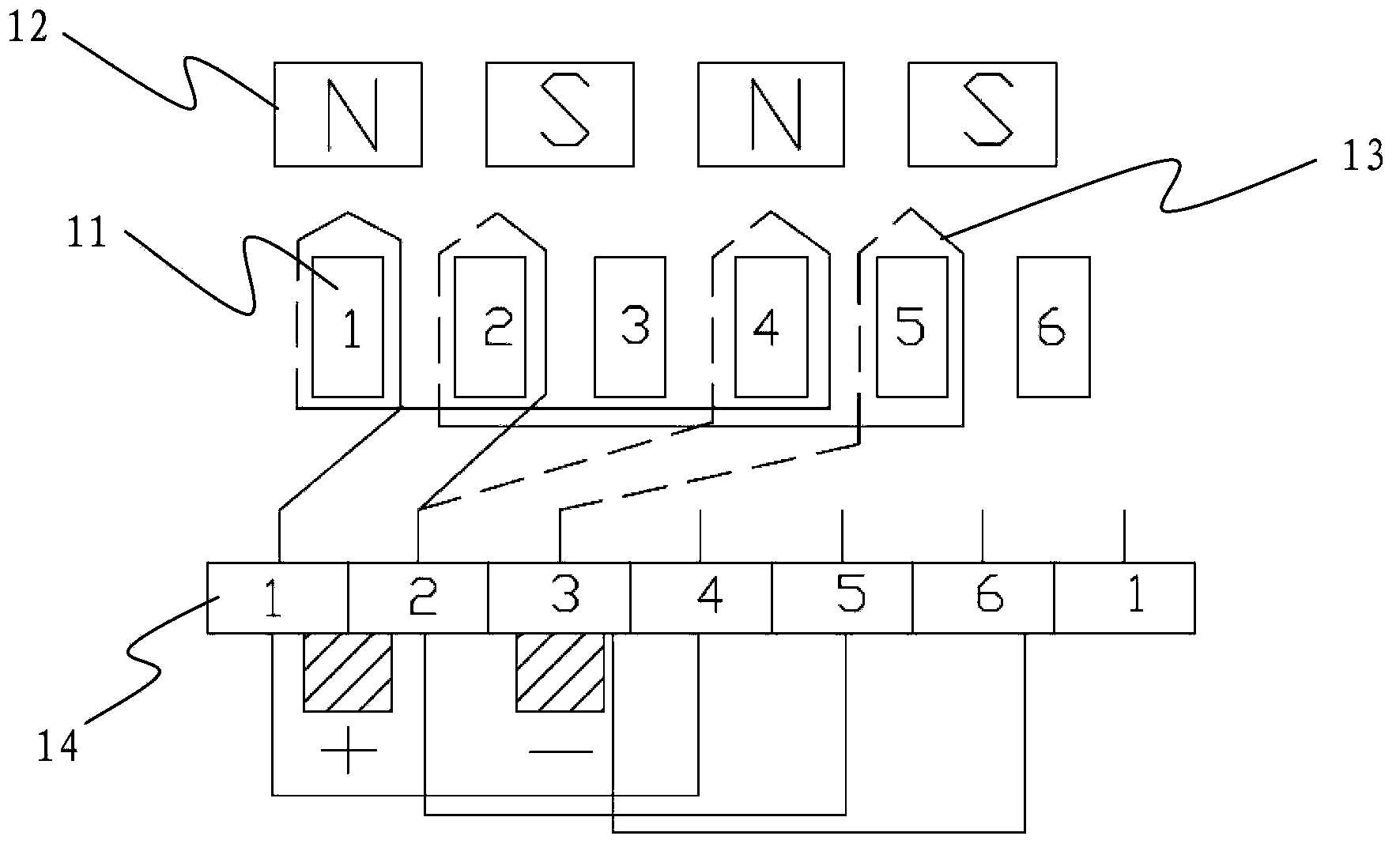

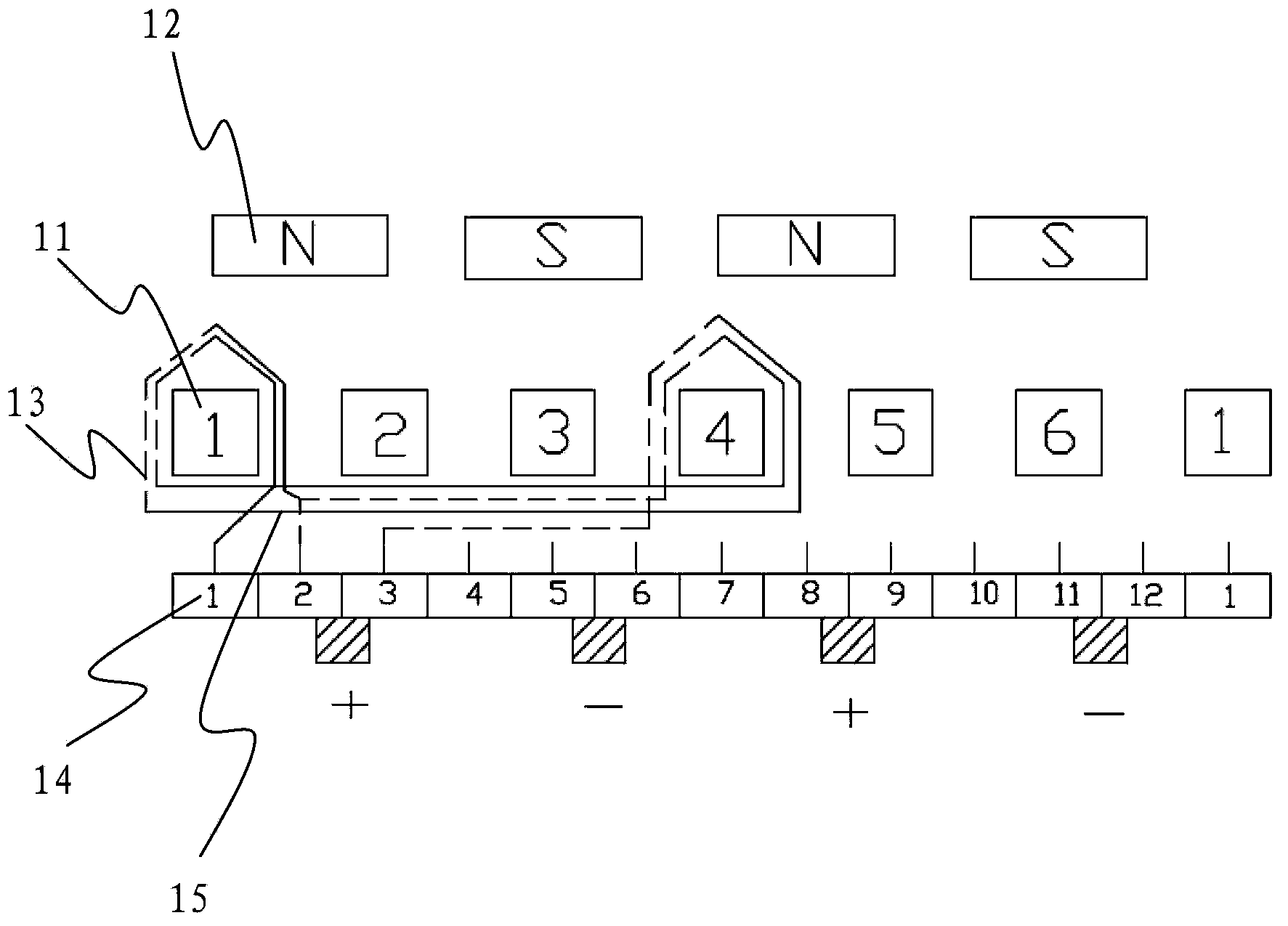

[0019] see first figure 2 As shown, the winding structure of the permanent magnet brushed motor for six slots and four poles of the present invention includes 6 winding grooves 11, 2 pairs of magnetic steel 12 and 6 commutator segments 14, the original one is replaced in the present invention The coils on the winding slots are sequentially wound on two winding slots 11: for example, on the No. 1 winding slot and the No. 4 winding slot, two coils 13 are formed, wherein the No. 1 wire slot and the No. 4 winding slot The geometric relative position of the magnetic steel 12 is the same, and they are all located under the N pole. Therefore, compared with the original structure winding method, the two coils 13 wound on the No. 1 wire slot and the No. The geometric relative position of the commutation coil 13 is also the same, and so on, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com